- Joined

- Nov 26, 2005

- Messages

- 5,017

- Reaction score

- 9,965

Hi,

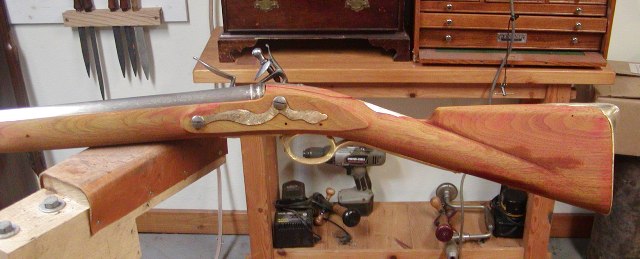

I refined the stock a bit more and inlet the trigger guard. When inletting these long guards, install the front first, pin it and then cut the mortise for the rear of the guard working backward. As the guard is set in, the rear will migrate forward so you have to plan for that. Fortunately, a Bess guard is very shallowly inlet so that forward movement is reduced a lot.

The forward part of the bow should sit down on the trigger plate with no gap. The forward part of the trigger plate is inlet a little lower than the surface of the wood so the guard can sit down into its mortise.

After installing the guard, I rounded the bottom of the stock. More wood will be removed from the sides thining the butt stock a bit.

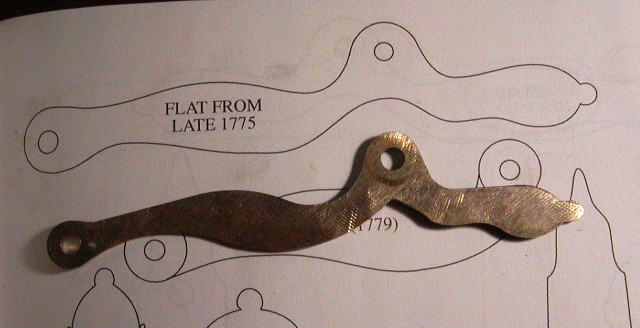

I began installing the thumb plate. First, I lined out the assembly using my drawings such that the bolt going through the wrist and attaching the thumb plate also anchors the trigger guard behind the bow and the rear of the trigger plate. The I marked the hole on the trigger guard, drilled through it and the trigger plate but only partially through through the stock. Then I located where I wanted the hole to end up on the top of the wrist, drilled down from that point until I met the other hole. Then I used a larger clearance drill sized for a 10-32 bolt to drill through the entire thickness from the trigger guard side. Finally, I drilled a hole large enough to fit the boss under the thumb plate a short way into the wrist from the top. Next I place the thumb plate down into the hole on top and remove wood from the center of the mortise.

This allows the plate to sit down on the stock enabling me to outline it accurately. I'll post photos of the finished plate later.

dave

I refined the stock a bit more and inlet the trigger guard. When inletting these long guards, install the front first, pin it and then cut the mortise for the rear of the guard working backward. As the guard is set in, the rear will migrate forward so you have to plan for that. Fortunately, a Bess guard is very shallowly inlet so that forward movement is reduced a lot.

The forward part of the bow should sit down on the trigger plate with no gap. The forward part of the trigger plate is inlet a little lower than the surface of the wood so the guard can sit down into its mortise.

After installing the guard, I rounded the bottom of the stock. More wood will be removed from the sides thining the butt stock a bit.

I began installing the thumb plate. First, I lined out the assembly using my drawings such that the bolt going through the wrist and attaching the thumb plate also anchors the trigger guard behind the bow and the rear of the trigger plate. The I marked the hole on the trigger guard, drilled through it and the trigger plate but only partially through through the stock. Then I located where I wanted the hole to end up on the top of the wrist, drilled down from that point until I met the other hole. Then I used a larger clearance drill sized for a 10-32 bolt to drill through the entire thickness from the trigger guard side. Finally, I drilled a hole large enough to fit the boss under the thumb plate a short way into the wrist from the top. Next I place the thumb plate down into the hole on top and remove wood from the center of the mortise.

This allows the plate to sit down on the stock enabling me to outline it accurately. I'll post photos of the finished plate later.

dave