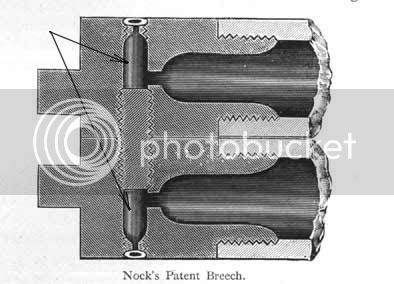

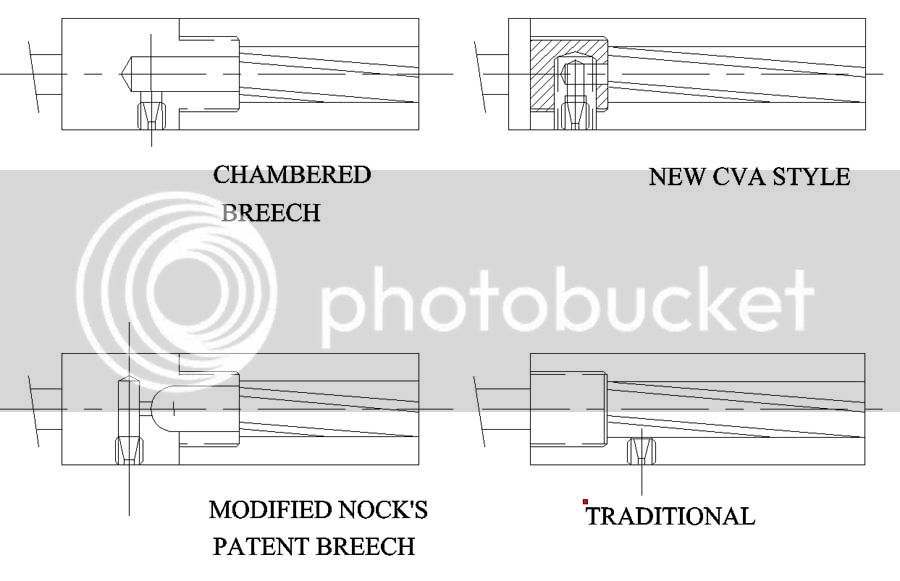

I for one think some patent or chambered breeches are too complicated...which brings up the question on your drawing....as pictured, how is the flash channel from the nipple to the ante chamber drilled?

I have a "kit" TC Hawken that I assembled {built} in 1976 and have never had a problem whatsoever w/ it not firing. Judging from the pipe cleaner that I've inserted into the flash channel after removing the clean out screw, the flash channel pretty near goes straight into the ante chamber...which is a good way to have it.

Early on after a few cleanings in a bucket of hot water, I no longer removed the cleanout screw....the ante chamber and flash channel were cleaned w/ a few pumps of the swab.

Built a Stith Hawken for a customer and the percussion patent breech whatever brand it was, had a tendency to clean well in a bucket of water, but when a patch was swabbed down the bore, it sometimes failed to fire..... a wire brush in lieu of a patch solved this problem.

The drum and nipple is much simpler and dependable than the chambered breeches, etc, but isn't as sturdy.

TC's breech is the best out there and evidently they researched which type of chambered breech is the most foolproof and took heed.

Flintlocks usually need a little more "care" than caplocks, but some caplocks w/ the various types of chambered breeches also require some "care". This shouldn't be necessary w/ a caplock.....Fred