-

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Percussion to Flint

- Thread starter Jo

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

first you will need a lock. then you will have to get a touch hole. if it has a screw in bolster{cva} just unscrew it and put in a touch hole liner. if it has a forged bolster{t-c} you either have to change the breach or mill the one you have flat and drill and tap it for a liner. now with all this changing you have to make everything line up.

mite be easier to buy a flint and sell the cap lock.

mite be easier to buy a flint and sell the cap lock.

There are several different types of "screw in" bolster's.

Not knowing what rifle you have makes it difficult to say exactly what you are dealing with.

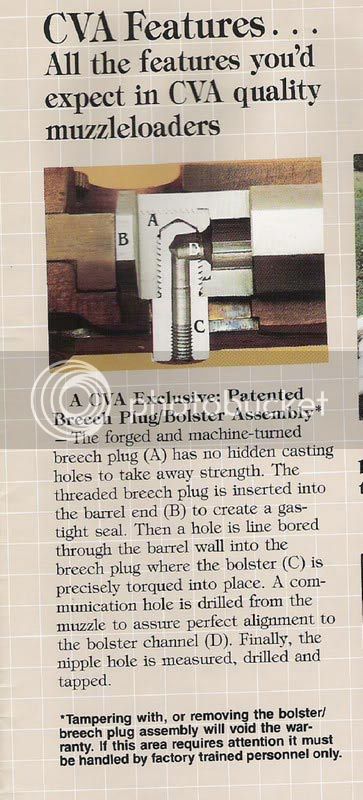

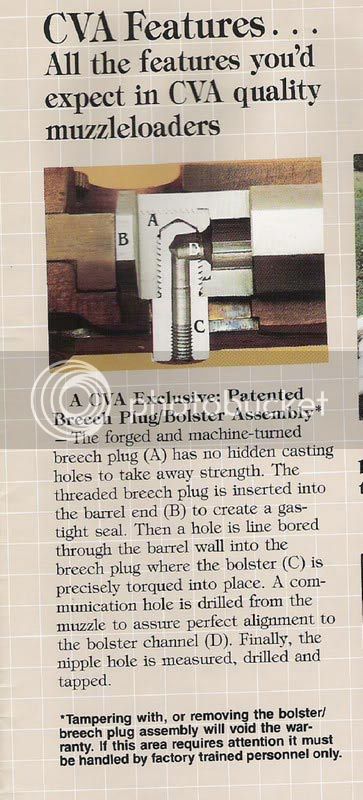

If it is a CVA or a Traditions, a cross-section thru the breech looks like this.

Notice, if you remove the "drum" you will end up with a huge hole to fill.

Obviously not the way to go.

With breeches like this, the best way to do it in my opinion is to cut off the protruding area of the drum and file it flush with the barrel's side flat. Then, run a tap drill into what's left of the flame channel (the hole that goes to the rear of the bore), and then thread the new hole for the thread size that is on your newly purchased vent liner.

The location of your new vent liner to the lock is pretty much fixed. That is, you can't do much to change its location but if you can find a CVA or Traditions flint lock to replace the percussion lock, it will be very close to the correct place.

One of the nice things about building a flintlock is, the location of the vent hole isn't too important.

As long as it is above the bottom of the pan and below the top of the "lid" on the frizzen when it is closed and somewhere between the front and rear of the pan, it will work. Of course, the closer it is to the middle of the pan and in line with the top surface of the pan (with the frizzen forward) the better but if it is off a bit, it will still work.

Now, if your gun is a custom made one, your barrel will most likely look like this:

If this is the case, you can just remove the drum and screw a flintlock vent liner into the barrel.

Not knowing what rifle you have makes it difficult to say exactly what you are dealing with.

If it is a CVA or a Traditions, a cross-section thru the breech looks like this.

Notice, if you remove the "drum" you will end up with a huge hole to fill.

Obviously not the way to go.

With breeches like this, the best way to do it in my opinion is to cut off the protruding area of the drum and file it flush with the barrel's side flat. Then, run a tap drill into what's left of the flame channel (the hole that goes to the rear of the bore), and then thread the new hole for the thread size that is on your newly purchased vent liner.

The location of your new vent liner to the lock is pretty much fixed. That is, you can't do much to change its location but if you can find a CVA or Traditions flint lock to replace the percussion lock, it will be very close to the correct place.

One of the nice things about building a flintlock is, the location of the vent hole isn't too important.

As long as it is above the bottom of the pan and below the top of the "lid" on the frizzen when it is closed and somewhere between the front and rear of the pan, it will work. Of course, the closer it is to the middle of the pan and in line with the top surface of the pan (with the frizzen forward) the better but if it is off a bit, it will still work.

Now, if your gun is a custom made one, your barrel will most likely look like this:

If this is the case, you can just remove the drum and screw a flintlock vent liner into the barrel.

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,034

- Reaction score

- 1,407

Odds are pretty good that the sizes won't line up perfectly. Likely you'll wind up with filing the drum off flush, and then installing a vent liner in to the existing stub remnant of the drum base.

Go slow with the filing though, and resist the temptation to use a grinding wheel. I'd use a hack saw to start with. You want to guard against building up too much heat, and softening the steel. Many times I've tried to trim excess off of areas that are soft soldered together with the grinding wheel, only to have the joints get loose in the process. that's not applicable in this case, but just a general hint.

Go slow with the filing though, and resist the temptation to use a grinding wheel. I'd use a hack saw to start with. You want to guard against building up too much heat, and softening the steel. Many times I've tried to trim excess off of areas that are soft soldered together with the grinding wheel, only to have the joints get loose in the process. that's not applicable in this case, but just a general hint.

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,034

- Reaction score

- 1,407

I think that if you get it too hot you can heat harden it, which might make it brittle. But I defer to those that know way more than me on the subject. I've never seen a discussion on how our barrels and parts are treated or tempered, other than zillions of them regarding how to treat frizzens.

Almost all of the barrels and breech plugs on muzzleloading rifles are left soft, as it comes from the steel mill.

In fact, almost all are made out of low carbon steel of one type or another that cannot be heat hardened.

While it is true that these low carbon steels can "work harden" if they are left in a "Cold Rolled" state and this does change their tensile strength and elongation properties slightly, the change is not in the best interests of using the steel for a barrel.

In other words, annealing the steel by heat treating cold rolled steel improves the mechanical properties in a black powder muzzleloading barrel or breech plug.

The improvement is so slight that IMO, it isn't worth adding this annealing process to the manufactured barrel.

If the barrel, breech plug, drum or bolster was made from Hot Rolled Steel, it is as soft as it can get so it will not change at all if it is heated by any means.

The bottom line is this:

Any change due to heat from grinding on the barrel, breech plug or bolster isn't worth worrying about.

In fact, almost all are made out of low carbon steel of one type or another that cannot be heat hardened.

While it is true that these low carbon steels can "work harden" if they are left in a "Cold Rolled" state and this does change their tensile strength and elongation properties slightly, the change is not in the best interests of using the steel for a barrel.

In other words, annealing the steel by heat treating cold rolled steel improves the mechanical properties in a black powder muzzleloading barrel or breech plug.

The improvement is so slight that IMO, it isn't worth adding this annealing process to the manufactured barrel.

If the barrel, breech plug, drum or bolster was made from Hot Rolled Steel, it is as soft as it can get so it will not change at all if it is heated by any means.

The bottom line is this:

Any change due to heat from grinding on the barrel, breech plug or bolster isn't worth worrying about.

Col. Batguano

75 Cal.

- Joined

- Feb 10, 2011

- Messages

- 5,034

- Reaction score

- 1,407

Zonie said:The bottom line is this:

Any change due to heat from grinding on the barrel, breech plug or bolster isn't worth worrying about.

That's great to know. I was worried about the tang on a breech plug that broke on me and I had to weld back together. Now I won't any more

AZbpBurner

54 Cal.

I looked at a rifle my Dad built in 1970 with the thought of converting it to flint. Seems simple enough, but getting everything to line up without doing a lot of woodwork convinced me that simply getting a flint rifle & leaving my family heirloom alone was the smartest bet.

For a heirloom like that, I think you are doing the best thing.

I have several things my dad made and I wouldn't sell or alter any of them.

Perhaps they wouldn't be worth a lot to anyone else but to me they are priceless.

I have several things my dad made and I wouldn't sell or alter any of them.

Perhaps they wouldn't be worth a lot to anyone else but to me they are priceless.

Similar threads

- Replies

- 50

- Views

- 2K

- Replies

- 39

- Views

- 2K

- Replies

- 10

- Views

- 475

- Replies

- 1

- Views

- 211