- Joined

- Nov 26, 2005

- Messages

- 5,017

- Reaction score

- 9,964

Hi,

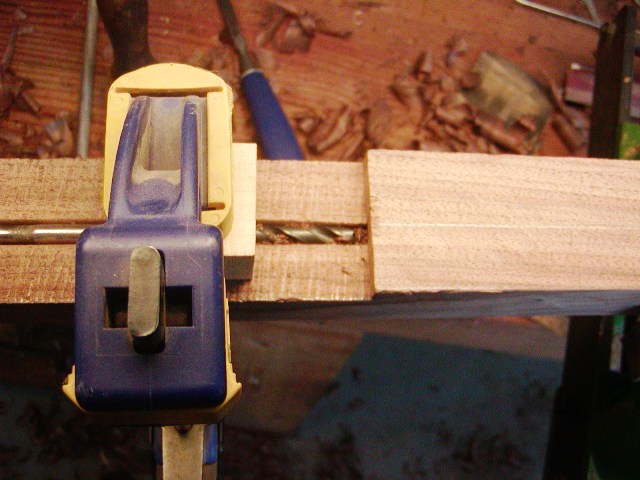

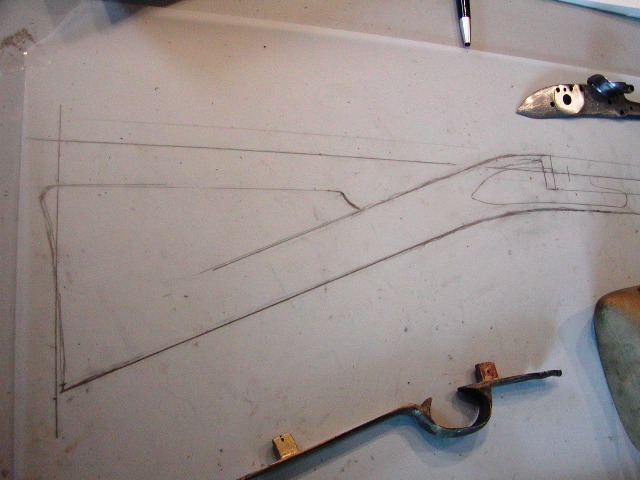

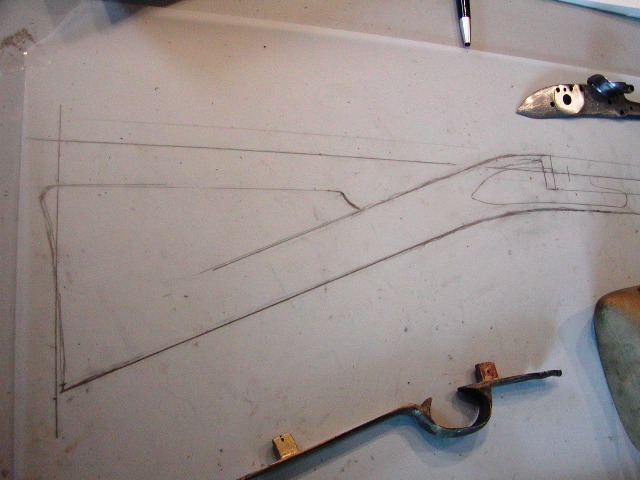

Thanks for all your comments and support. The project will be more fun now making a proper stock. I began my drawings and have the profile done sufficient for band sawing out the blank.

You can see the difference it will make from the old stock.

I dug into more of my references and notes for any further details on the Irish muskets. I think I have a good plan, which includes swapping out the Pedersoli trigger guard for one from an old Miroku Bess. I annealed the guard and then hammered out the odd crushed flattened, shape of the Miroku so it looks correct. It is much heavier brass, which is closer to the heavy, clumsier brass used on the Irish guns. As I was digging into the details I noticed many stock dimensions associated with Liege made Bess copies are similar to the Pedersoli Bess. In particular the butt plate dimensions and shape are spot on. Moreover, those muskets were of notoriously poor quality such that surviving examples often have replaced locks, frizzens, and flint cocks. I have a feeling that the prototype Bess sent to Pedersoli by Val Forgett and Turner Kirkland back in the early 1960s was a Liege gun with a replaced lock that happened to be marked "Grice 1762". Perhaps it was salvaged from an old long land musket or marine and militia musket. Back then there wasn't nearly the detailed scholarship on Besses that we have today so they may not have known any better. British ordnance got rid of the Liege contract guns as soon as they could but some may have been issued to loyalist units in America.

dave

Thanks for all your comments and support. The project will be more fun now making a proper stock. I began my drawings and have the profile done sufficient for band sawing out the blank.

You can see the difference it will make from the old stock.

I dug into more of my references and notes for any further details on the Irish muskets. I think I have a good plan, which includes swapping out the Pedersoli trigger guard for one from an old Miroku Bess. I annealed the guard and then hammered out the odd crushed flattened, shape of the Miroku so it looks correct. It is much heavier brass, which is closer to the heavy, clumsier brass used on the Irish guns. As I was digging into the details I noticed many stock dimensions associated with Liege made Bess copies are similar to the Pedersoli Bess. In particular the butt plate dimensions and shape are spot on. Moreover, those muskets were of notoriously poor quality such that surviving examples often have replaced locks, frizzens, and flint cocks. I have a feeling that the prototype Bess sent to Pedersoli by Val Forgett and Turner Kirkland back in the early 1960s was a Liege gun with a replaced lock that happened to be marked "Grice 1762". Perhaps it was salvaged from an old long land musket or marine and militia musket. Back then there wasn't nearly the detailed scholarship on Besses that we have today so they may not have known any better. British ordnance got rid of the Liege contract guns as soon as they could but some may have been issued to loyalist units in America.

dave