- Joined

- Nov 26, 2005

- Messages

- 5,024

- Reaction score

- 9,998

Good PNC,Excellent tutorial, Dave. I am learning many things from you here, thank you!

That is what this forum and the ALR forum are all about.

dave

Good PNC,Excellent tutorial, Dave. I am learning many things from you here, thank you!

Hi Simon,

I've thought about that. I figured since one of Jim Kibler's CNC machines did 90% of the work, I thought I would sign it with my name and the serial number of that machine.Just kidding. I am planning on signing it and engraving "Braintree Hill" which is my shop.

dave

Hi Norman,Are the plier and other tools something you make?

WowHi Norman,

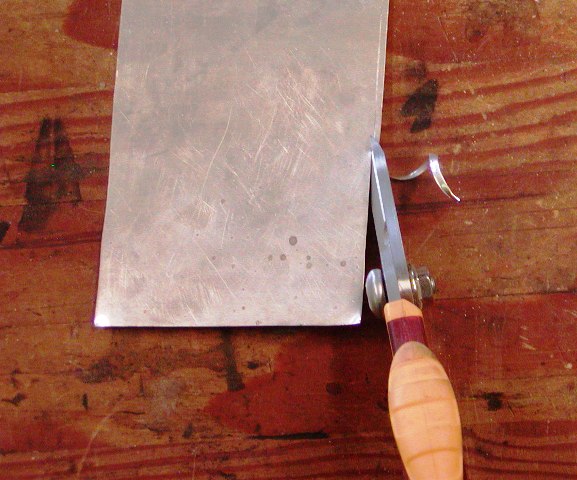

They are purchased from Rio Grande jewelry supply (www.riogrande.com). You can easily do the same thing just by having some metal or wooden pegs of different sizes to wrap the ribbon around. I just find the pliers to be a little more flexible for shaping the wire before inserting it. I have a great video of Frank Bartlett, one of the best wire men ever, working on a rifle. He used a screw driver sharpened for making the incised lines, then used the shaft for bending the wire when needed, and then the top of the handle to tap the wire in place. He essentially used one tool, which almost never left his hand. Frank could decorate an entire rifle with extensive wire inlay in 1-2 hours. I am not at that level yet. I go a bit slower and use more tools.

dave

Hi,

Finished the wire work on the cheek piece side. I added some fine silver wire to thicken the front edges of the small cloud, which gives it a little more mass and a bright edge reflecting sunlight. I more or less copied a Moravian star on one of Christian Oerter's rifles but did it in wire rather than solid silver. The wire matches his engraving. I am going to put some wire on the patch box side, then finish all the carving. Since the owner lives in Florida, maybe I'll do a hurricane scene, or the Little Mermaid from Disney World, or some old guy playing golf.After that, stain.

dave

Hi Simon,

It will be something historically correct. I have a bunch of ideas in my head that I have to sort through.

dave

Enter your email address to join: