bore_butter

36 Cal.

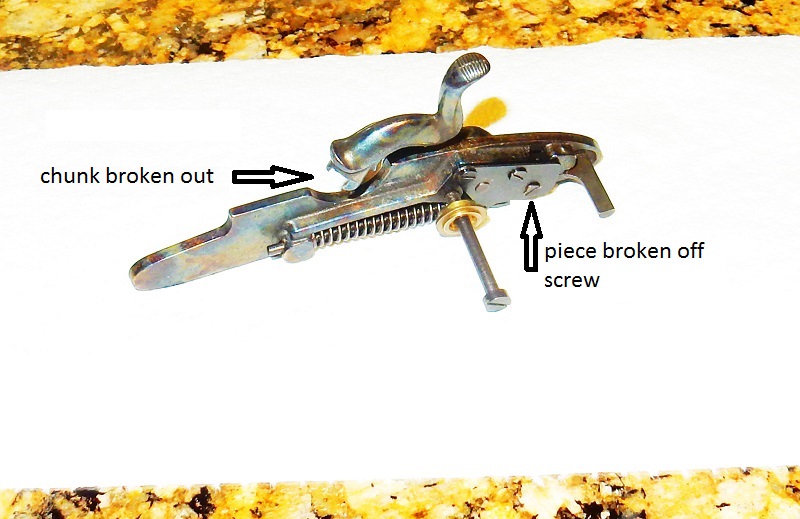

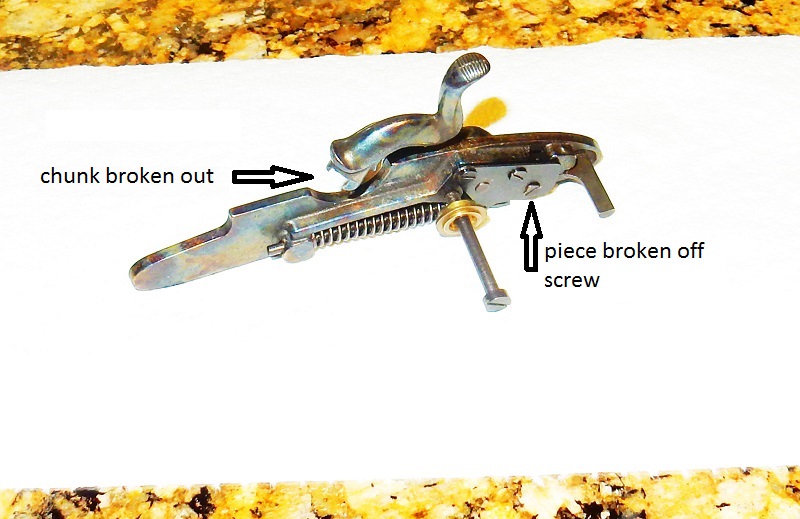

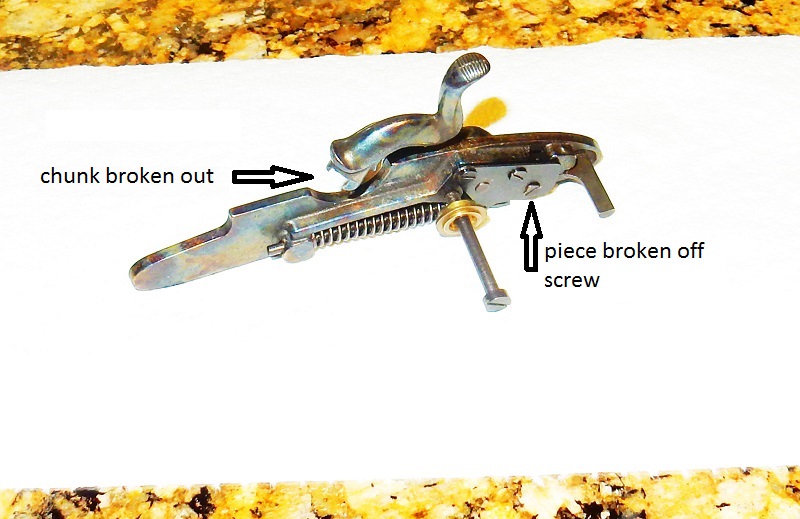

this plate is bent, can it be pressed flat without applying heat?

DoubleDeuce 1 said:It’s difficult to see where the plate is bent. Does the bend in the plate hamper the function of the hammer ? How was the hammer chipped ? Can you fit a small shim under the plate to straighten it out when you put the lock back into the stock ? Does the lock mortise need a slight adjustment where the bend in the plate is ? :hmm:

I had forgotten you said that was a new hammer. Not likely to be bent, and since its the second on the rifle even less likely BOTH would be bent. I'd go with your original assessment that the plate is somehow bent or twisted slightly

I had forgotten you said that was a new hammer. Not likely to be bent, and since its the second on the rifle even less likely BOTH would be bent. I'd go with your original assessment that the plate is somehow bent or twisted slightly

Enter your email address to join: