The

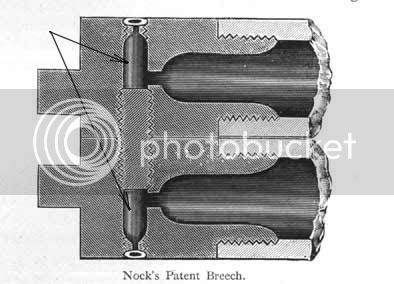

original Patent breech was designed and Patented by Nock, the noted London gunsmith in the era of the Flintlock.

It looked like this:

The purpose of this design was to create an anti-chamber which would self load with powder during loading.

The ignition of the small powder charge created a jet of flame thru the small connecting hole into the main powder charge and was supposed to provide increased velocity and less fouling.

Some testing that I've read about seemed to prove the theory was correct.

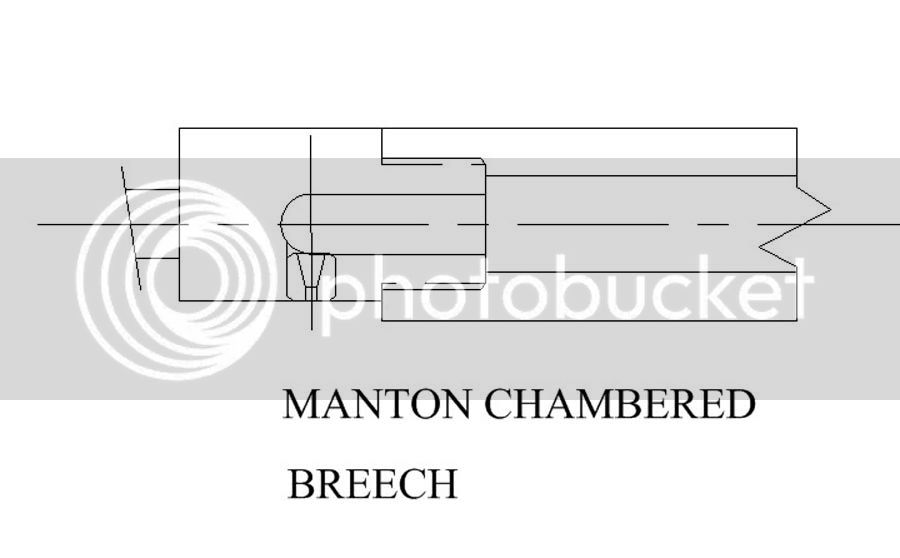

Because of Nock's Patent his competition couldn't use it in their guns so Manton used the "chambered breech" that so many of us wrongly call a patent breech.

It too is supposed to create a jet of flame to improve the ignition of the main powder charge.

Below is a sketch of this

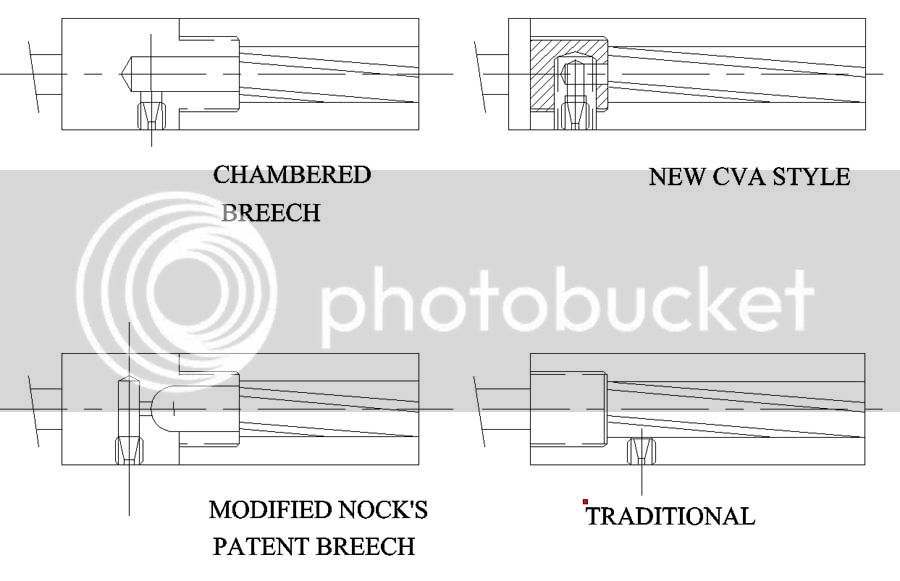

In the late 1970's or early 1980's Ardesa in Spain created their own design of a breech that would provide improved ignition.

They did Patent this design so when people are speaking of the CVA's breech and calling it a Patent breech they are correct. They are refering to a different Patent though as it is different than Nocks original design.

Here's a drawing showing the typical flintlock breeches found in most muzzleloading rifles.

The percussion breeches are similar but use a flame channel to connect the breech with the nipple.