mikemeteor

45 Cal.

- Joined

- Nov 16, 2008

- Messages

- 660

- Reaction score

- 3

Started to rust brown my barrel (Green Mountain) today with LMF.

Wet sanded with 180.

Cleaned with brake cleaner.

Wiped down with denatured alcohol.

Wore gloves.

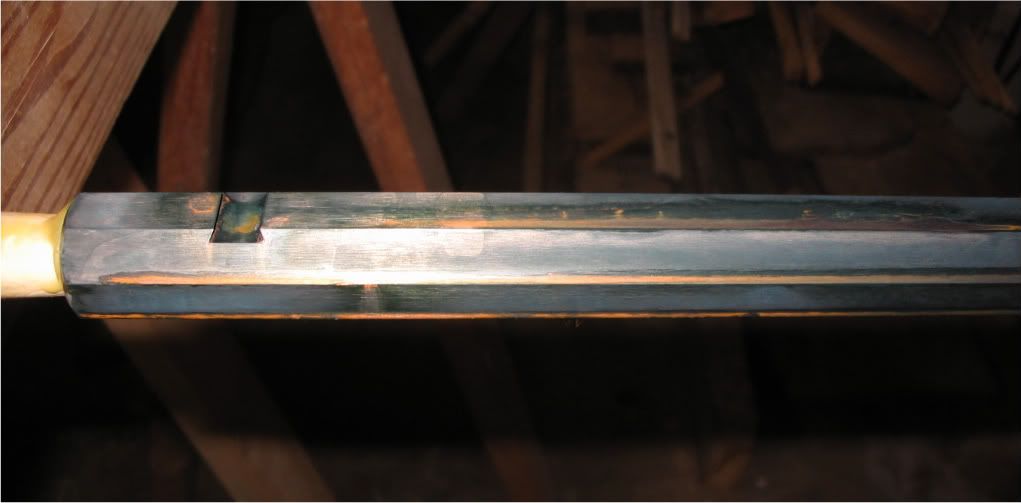

First coat of LMF pretty much went right to black, with a little coppering:

Wasn't sure if that was right - it sure didn't look like rust !

Rubbed that back with some de-oiled steel wool.

Second coat went immediately to black too:

Is this the way its supposed to look ?

Or am I doing something wrong ?

Guess I was expecting some reddish brown rust-colored scale.

It's fairly humid and about 70-degrees in the shop.

Wet sanded with 180.

Cleaned with brake cleaner.

Wiped down with denatured alcohol.

Wore gloves.

First coat of LMF pretty much went right to black, with a little coppering:

Wasn't sure if that was right - it sure didn't look like rust !

Rubbed that back with some de-oiled steel wool.

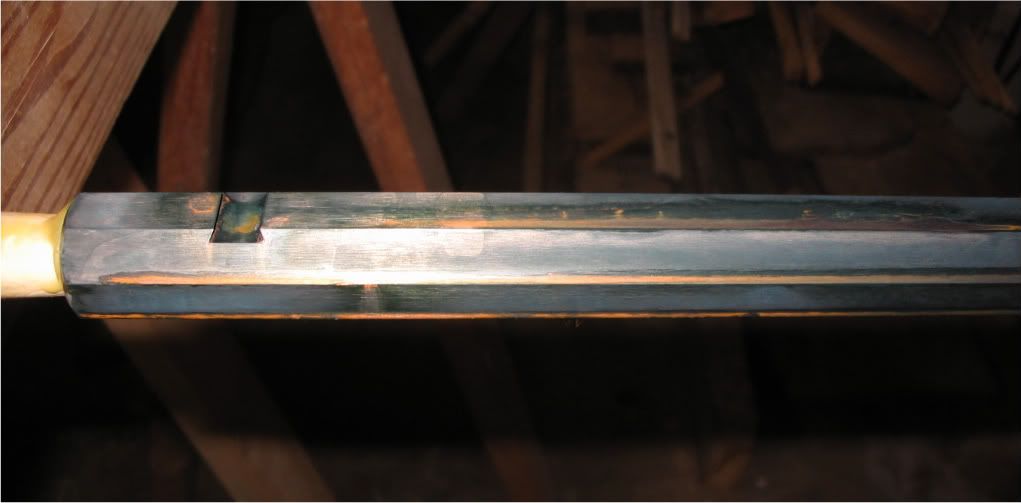

Second coat went immediately to black too:

Is this the way its supposed to look ?

Or am I doing something wrong ?

Guess I was expecting some reddish brown rust-colored scale.

It's fairly humid and about 70-degrees in the shop.