A while ago, I started a post on the Percussion Gun page named "Leman Rifle".

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/228467/

Long story short, I'm re-stocking a CVA Tennessee Rifle to a Leman stock.

I've got the barrel inlet to the stock, ribs are all set.

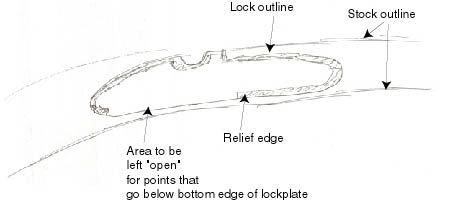

I'm ready to start inletting the lock (the original CVA lock).

Am I correct in thinking that the lock is WAY too small for the lock panel as is?

If it is too small, I've got to shape the lock panel down. Should I make it about 1/8" (slightly more at the front & back) larger than the lock? Is that a good dimension to aim for? I'll do my best to keep the shape of the panels.

Part 2... Inlet the lock first, or shape the panel first?

Thanks in advance,

WindLaker

http://www.muzzleloadingforum.com/fusionbb/showtopic.php?tid/228467/

Long story short, I'm re-stocking a CVA Tennessee Rifle to a Leman stock.

I've got the barrel inlet to the stock, ribs are all set.

I'm ready to start inletting the lock (the original CVA lock).

Am I correct in thinking that the lock is WAY too small for the lock panel as is?

If it is too small, I've got to shape the lock panel down. Should I make it about 1/8" (slightly more at the front & back) larger than the lock? Is that a good dimension to aim for? I'll do my best to keep the shape of the panels.

Part 2... Inlet the lock first, or shape the panel first?

Thanks in advance,

WindLaker

Last edited by a moderator: