armakiller said:

:bull: on your 12L14 take on things. If this was "extremely common" barrel makers such as Colerain, Rice, and Don Getz would be out of business because people would stop using their barrels and you would see more posts about "Burst Barrels" either on here or on ALR. Also the post you put up is unreadable (the typing is to small). I still believe it was a short started round up by the muzzle of the gun because if it was close to the breech you would see a barrel that looked liked the one on page 2, because you would have a sudden pressure build up that would burst the barrel. This barrel looks more like it POPPED when the pressure hit the round up by the muzzle. :2 .

First this is not the first blown up ML barrel I have seen or saw photos of. The first was back about 1969 with a major maker of ML barrels at the time had several (well 2 at least) failures in 45 cal barrels. One I examined the other was described in Muzzle Blasts by Roy Keeler who I used to buy parts from. BTW the maker would not allow him to buy barrels from them any longer.

These had both failed by splitting up the top flat from just in front of the breech to or beyond the rear sight. It is interesting to note that these brittle steels break in a manner that often causes the crack to out pace the projectile and sometimes it or the patch will be stuck in the crack if the barrel does not fragment.

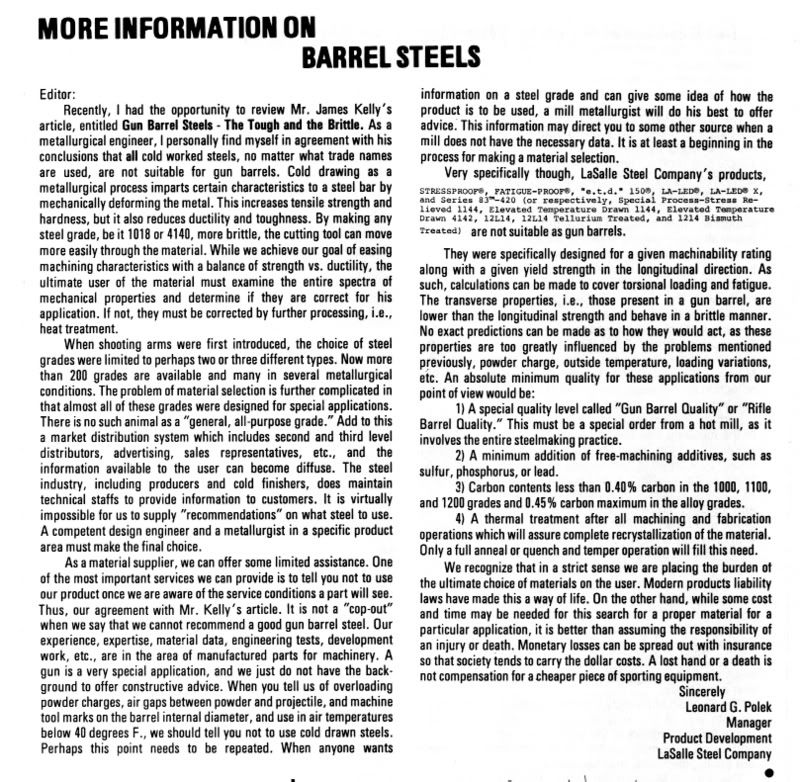

Look this is not "my take" this is LaSalle Steel, a metallurgist who worked in failure analysis and a number of barrel makers who do not use the stuff. Its unsuitable for gun barrels. This guy is not the only metallurgist that I have heard from on this matter. One who would not even contact me personally (gun barrels invariably mean lawsuit to metallurgists) was a Professor of Metallurgy and in response to my question about using Stressproof (1144 cold rolled and its really not Stressproof except perhaps in

carefully machined shafts used to drive machinery, some people I used to work for used it for this of not very carefully contoured it would break) for gun barrels he simply replied "why would anyone use anything but Chrom-moly (meaning 4140-50 series) that ALL I got. He figured I was fishing for an expert witness and only answered through 2 other people. I could relate a company I used to work for losing about 10% of the 1144 blanks they were button rifling but I have spent too much time on this already.

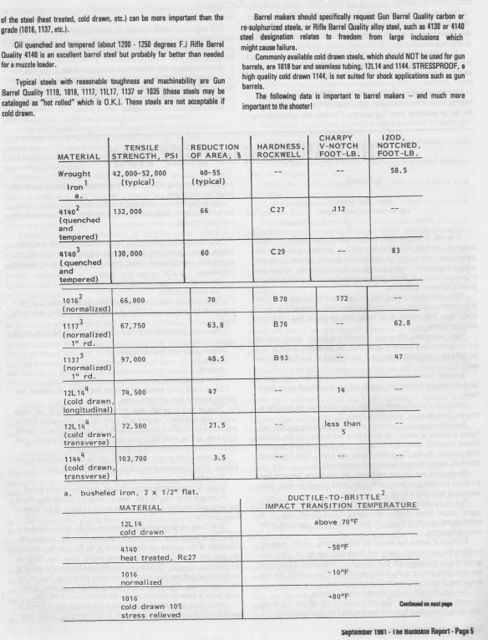

Next if the barrel were not brittle it would not burst as a result of a short start ball it will only bulge. But of course this has to be false too since the common unsuitable brittle steels almost invariably split or burst. Another little fact is that the colder it gets the more likely the failure. Some stainless steels used in barrels 416-416R are also brittle free machining steels. If you go to Krieger's site, for example you will see that they do not recommend them for hunting rifles or firing a stainless barrel under 0f and state that they should not be re-contoured.

Then we have a big name ML barrel maker stating, in print, that if they are tuning a barrel blank and a crack appears they keep turning and if if disappears they use the blank anyway. As a friedn who started making MLs in the late 1940s states, what about the cracks they do not see? This is at

Proof testing

Go down the thread you'll find it.

Then we have other parts made of free machining steels. Like drums. If modern drums are used in an unsupported application, not bearing on the lock plate, they tend to BREAK OFF after being used for awhile. I had this happen back in my teens, drum went through a screen door. A friend told me at a rifle match that he had one break in the same manner. Drums made in the 19th c jsut bend (I have one from an 1830s-40s percussion rifle barrel in my collection, very small shank and its bent slightly, ductile iron I am sure)

The brittleness of this material (it cuts cleaner), coupled with the high levels of lubricating metals (to make is cut nice and fast and smooth) result in a material that will fail from internal pressure that is perhaps 10% of its listed tensile strength. So a hot rolled steel, of a good grade (this means minimal inclusions and flaws steel comes in numerous grades that are certified including but not limited to Gun Barrel, Air Craft and Nuclear) even in 1010 or 1018 will work very well for low pressure gun barrels even though its "weaker" than 12L14 or 1144. Its makes stronger barrels, the cold rolled steels produce better tensile tests. A large number, perhaps hundreds of thousands, of 1911 pistols in 45ACP were made with high quality steel 1010 or very similar steels.

A big name in barrels stopped making ML barrels after one of their 12L14 barrels maimed a shooter (remember the cracked barrels mentioned above? Same company). Near the end of production they were annealing the 12L14 to make it more ductile at least exterior of the barrels were scaled from heat. This has its own problems with the lead level present but I did see a 12L14 of their make that only bulged from a ball seated about 12" from the muzzle. It should have cracked but did not. Remington was sued over using 1140M for shotgun barrels and several shooter were maimed. This stuff WORK HARDENS and becomes BRITTLE and some trap shooters who ran through a LOT of ammo had failures.

There are ML shooters who no go to re-enactments with one hand due to barrel failures. Yet everyone "knows" it was their fault right? People would not use faulty steel for gun barrels right?

Many years ago Dad dropped his M1 off a tractor and then shot at a Coyote with it with dirt in the barrel, the barrel had a bulge about 2" behind the gas port. He shot it for years afterwards until I finally rebarreled do to chlorate pits and the bulge. Why did this not banana peal? It certainly has a lot more "umph" in hitting a plug at 2700 fps than BP would.

Here is an idea. I have posted material generated by an Officer of LaSalle Steel and a Metallurgist. How about you getting some information from a steel maker and a metallurgist who has studied BARREL STEELS and have THEM write a rebuttal.

I closing I will say that I have been making MLs for almost 50 years. I worked as the "tech guy", gunsmith (only one in the building) and custom shop for a major American maker of 19th c single shots. Its not my first barn dance so to speak.

So contact that metallurgist I am waiting but not breathlessly.

By the way one of the NON 12L14 ML barrel makers I get barrels from sent me an email on other subjects and at the end he referred to one of the makers you mentioned in which he stated, "I see _____ is making another run of pipe bombs". Not all ML barrel makers use the stuff.

So far as being out of business? Yeah it makes me wonder. But then like you, people think that it must be the shooters fault. Afterall "you can't blow a ML barrel up with BP".

Dan