How far internally across should the bolster end be inside the breach plug, ie how much room does the ignition port need for reliable firing. When fitting a new bolster to mine, the end covers half the ignition port (central hole at the front of the breach plug). Should I leave as is or remove 1-2mm from it. (Sorry if my terminology isn't quite right).

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolster depth?

- Thread starter Jarikeen

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well....I guess you could say there is a definite problem with the description of the problem.

To my way of thinking, the bolster is the part of the lock that rests up against the side of the barrel.

After re-reading your post several times, I'm wondering if your gun has a seperate percussion drum with the nipple screwed into it, and the threaded part of this drum that screws into the barrel is interfering with the front of the breech plug???

Actually, your question is better served in the Gun Builders Forum, and I will move this there in a day of so. I'm mentioning this so you won't think it got lost.

If my guess (up above) is correct, the nipples flame channel needs to have a clear passage to the bore of the barrel. If it is half blocked off, the material that is creating the closure needs to be removed.

Before you start grinding material off though, you need to make another stab at describing exactly where and what the problem is.

zonie

To my way of thinking, the bolster is the part of the lock that rests up against the side of the barrel.

After re-reading your post several times, I'm wondering if your gun has a seperate percussion drum with the nipple screwed into it, and the threaded part of this drum that screws into the barrel is interfering with the front of the breech plug???

Actually, your question is better served in the Gun Builders Forum, and I will move this there in a day of so. I'm mentioning this so you won't think it got lost.

If my guess (up above) is correct, the nipples flame channel needs to have a clear passage to the bore of the barrel. If it is half blocked off, the material that is creating the closure needs to be removed.

Before you start grinding material off though, you need to make another stab at describing exactly where and what the problem is.

zonie

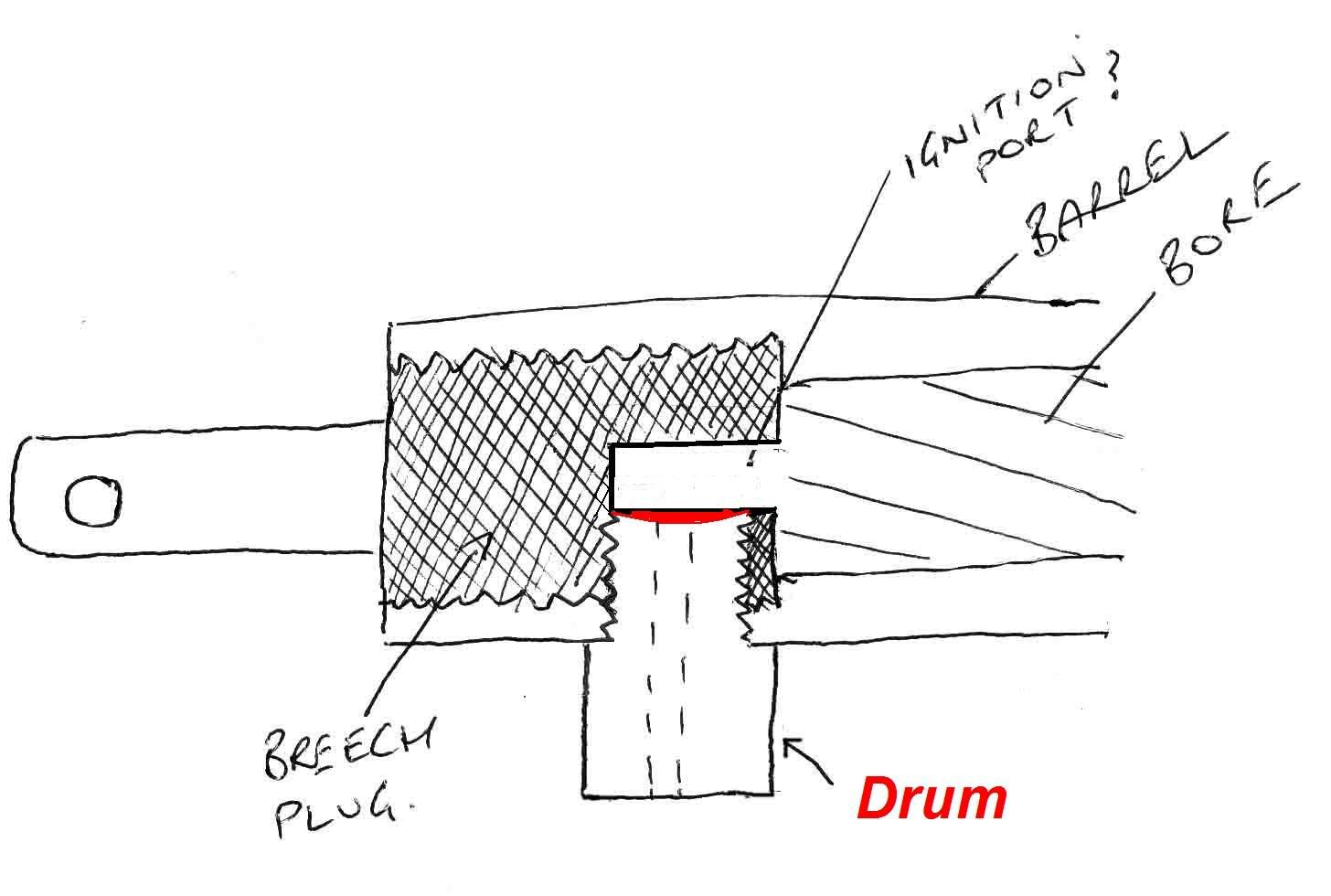

Thankyou for your reply Zonie. I didn't like how my decription read either, but was unsure of how to express it. The bolster thread is not long enough to go completely to the other side and I can't make it go further without mucking the nipple sideways placement. Here is a badly drawn picture which I hope shows what I was trying to say. The rifle is a Dikar.

The bolster/drum should only be done up nip tight, yes?

The bolster/drum should only be done up nip tight, yes?

It would appear to me, if I understand correctly, that you need to shorten the drum (you say "bolster") by a couple of threads. You do not want it to "reach the other side". Rather, you want the threaded shank of the drum to just reach the powder chamber without protruding into it.

Guest

Yoy may want to put a radius on the powder sac and the drum flash channel. That way the powder will not stack up but flow into the drum and fill up under the nipple for quicker ignition.

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 80

I agree with CoyoteJoe. What you are calling and labeling a " Bolster" is really the Drum, from a " Drum and Nipple" style percussion action. The Bolster is the enlarged portion at the top of the lock plate, on the inside of the lock that allows the lock plate to fit snuggly against the barrel, whether the barrel has flats, is round, or tapered. The bolster is filed and machined down to fit the barrel so there is no large gap where sparks or powder can get down into the lock mortise. Can you imagine what it would be like if your lock mortise became full of black powder and then a spark set it off as you fire your gun? The BOLSTER on a lock serves this safety issue, as well as keeps rain and snow out of the mortise , provided you seal the edge with beeswax, or some kind of grease or lube.

By your picture, you need to remove at least 2 threads from that drum. The drum should screw into the barrel, and in this case, into the " chamber " drilled into the breech plug face. It should not extend into that chamber, as your drawing shows, but stop at the edge of the chamber. This allows the flame to contact the powder in the chamber in the shorter distance, and also allows you to be able to clean the chamber with a properly sized bore brush, and scraper.

By your picture, you need to remove at least 2 threads from that drum. The drum should screw into the barrel, and in this case, into the " chamber " drilled into the breech plug face. It should not extend into that chamber, as your drawing shows, but stop at the edge of the chamber. This allows the flame to contact the powder in the chamber in the shorter distance, and also allows you to be able to clean the chamber with a properly sized bore brush, and scraper.

Guest

Isn't the term bolster is used to describe a nipple holder brazed to the outside of the barrel and used instead of a patent breech? Weren't flintlock muskets converted to percussion in this manner?

Well, according to my Webster BOLSTER may mean

"...any structural part designed to afford support...any contrivance that prevents chafing...the part of a knife blade that abuts upon the handle...the husk of the English walnut..."

It includes parts of wagons and railroad cars and the pillow that is used to support your head when your lying on the couch.

I have heard it used to describe the support for a percussion nipple on converted (and new) guns.

zonie

"...any structural part designed to afford support...any contrivance that prevents chafing...the part of a knife blade that abuts upon the handle...the husk of the English walnut..."

It includes parts of wagons and railroad cars and the pillow that is used to support your head when your lying on the couch.

I have heard it used to describe the support for a percussion nipple on converted (and new) guns.

zonie

paulvallandigham

Passed On

- Joined

- Jan 9, 2006

- Messages

- 17,538

- Reaction score

- 80

Zonie is obviously correct. However, on a flintlock, the bolster is on the inside of the lock plate, and is filed to marry the line of the barrel to the lock. There is a curved cutout for the frizzen pan, which is often welded or screwed into place, or both. On Percussion locks, the bolster is often cut out to provide a place for a separate drum to be screwed into the barrel, with the nipple screwed into the drum. On patent breeches, it is as you describe, with a portion either cast as part of the breechplug and tang, or welded to the side of the barrel providing a flash channel to the main charge chamber, and a place to screw in the nipple. Since a conversion of a flint lock will have a bolster on the inside of the lock plate, with a cutout for the flash pan, the flash pan is removed. Depending on design, additional metal may have to be added to fill any hole left between the lock plate and barrel when the flash pan was removed. This extra metal may be part of the modified breech, or a separate steel plate welded to the inside of the lock to seal the area, often leaving the cutout for the flashpan still visible. That is often the conclusive proof needed to tell that a gun has been converted from flint to percussion.

The analogy to a pillow at your head board on your bed is probably the best way to remember the purpose of the bolster, and its definition. The pillow provides a support for you head, and keeps things from falling down the crack at the end of the mattress. A Bolster supports the lock, and keeps things from falling down in the crack between the barrel and the lock plate.

The analogy to a pillow at your head board on your bed is probably the best way to remember the purpose of the bolster, and its definition. The pillow provides a support for you head, and keeps things from falling down the crack at the end of the mattress. A Bolster supports the lock, and keeps things from falling down in the crack between the barrel and the lock plate.

Guest

Ya mean like those two little bolsters on the underrib that bolsters the ram rod. Or, the bolster that holds the rampipes to the barrel? :hmm: :grin:

According to Webster, just about anything on a muzzleloading rifle CAN be called a bolster. Maybe, someone with the capabilities can post some pics with the correct nomenclature as to what we call these parts so everybody is speaking the same language. Maybe one picture with the modern terms used and one with the old terms that were historically used. What do you think, Musketman?

According to Webster, just about anything on a muzzleloading rifle CAN be called a bolster. Maybe, someone with the capabilities can post some pics with the correct nomenclature as to what we call these parts so everybody is speaking the same language. Maybe one picture with the modern terms used and one with the old terms that were historically used. What do you think, Musketman?

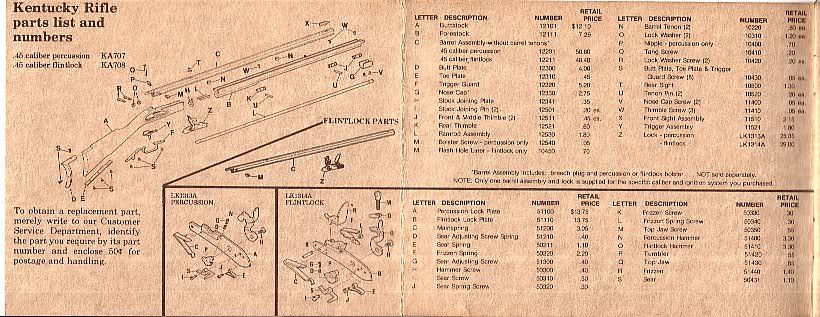

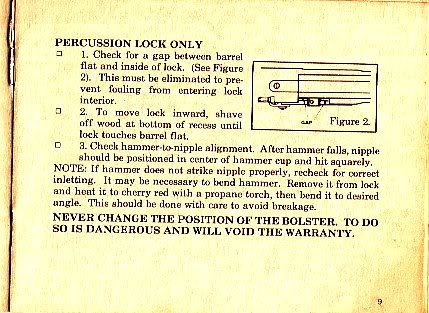

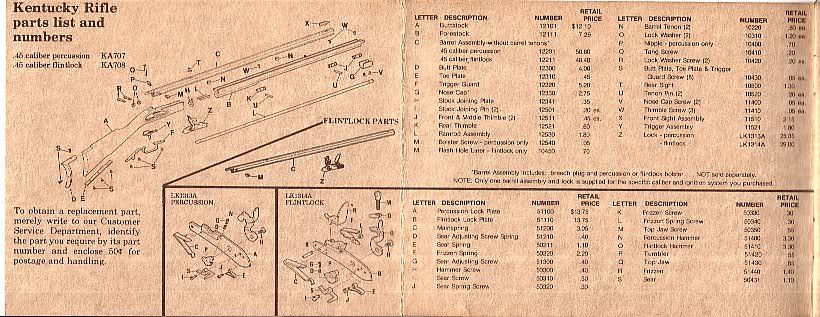

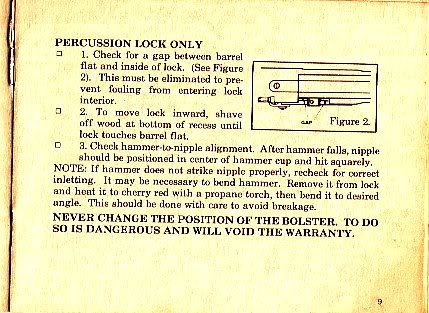

It has been bugging me about the Bolster reference....... Someplace sometime I have heard the drum referred to as a bolster. This morning it hit me where & I checked. Back in the 70's CVA was producing Kentucky Rifle Kits & Big Bore Mountain Rifle kits. In this kit the Drum is referrred to as a Bolster.

See ref. M, "Bolster Screw", which we refer to as a "Cleanout Screw".

Also, in the warranty referring to removal of the Drum, which they calll a Bolster:

Another part says:

Note: When the barrel is inletted, the bolster should sit into the semi-circular cutout in the lockplate.

See ref. M, "Bolster Screw", which we refer to as a "Cleanout Screw".

Also, in the warranty referring to removal of the Drum, which they calll a Bolster:

Another part says:

Note: When the barrel is inletted, the bolster should sit into the semi-circular cutout in the lockplate.

Guest

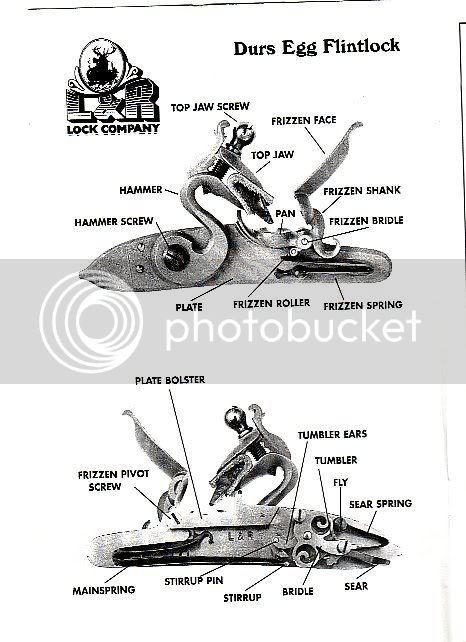

Man, there sure are a bunch a bolsters on a ML gun. And what I been calling a cock is a hammer on that drawing and what I been calling a steel or hammer is what they label a frizzen. :shake:

Guest

I have a gun in my posession with a bolster type breech, marked J.Fleeger and ALLEGHENY. It is a snail shaped piece of iron which resembles the Hawken patent breech in TOW's catalog. It is brazed or soldered directly to the angled and vertical flats of the breech end of the barrel where the drum would normally be. Somewhere in my references I have a book with a drawing of the same arrangement and it is labeled a bolster. I am certain that the US government converted many of its flintlock muskets to percussion using this method.

Terminology is a funny thing and probably varies from country to country. I'm only funnin' here - but maybe the bolster plate (the plate between the lockplate and the barrel) is called that because it sits under the bolster (drum).

To give an example - in America the word fanny mean your bottom, in Australia it means the something just in front of the bottom. Hope that is not too crude.

Cheers and thankyou all for your help. I'm only new to muzzle loading and this forum has helped fast track my learning curve incredibly.

To give an example - in America the word fanny mean your bottom, in Australia it means the something just in front of the bottom. Hope that is not too crude.

Cheers and thankyou all for your help. I'm only new to muzzle loading and this forum has helped fast track my learning curve incredibly.

Jarikeen said:The bolster/drum is done up nip tight, yes?

I think here is what is meant Jari. And yes it should be set up tite against the breech barrel joint. There should be no obstruction for the flame. Note the slight concave in red to help direc tthe flame and stop any edge obstruction in the "drum" You guys can feel free to correct me if I am inerror!:thumbsup:

Davy

I like the concave idea. After just reading another post where the person talks about the miss fires they get form the CVA drum setup I am wondering if I should perhaps use the current length but angle the face into the breach port.

Similar threads

- Replies

- 77

- Views

- 4K

- Replies

- 70

- Views

- 4K

Latest posts

-

FOR SALE GM drop in barrel .40 cal MINT

- Latest: adkmountainken

-

FOR SALE Excellent Ethan Allen by Hoppes .36 sxs Derringer

- Latest: BigSkyRambler

-

-

-

-

-

-