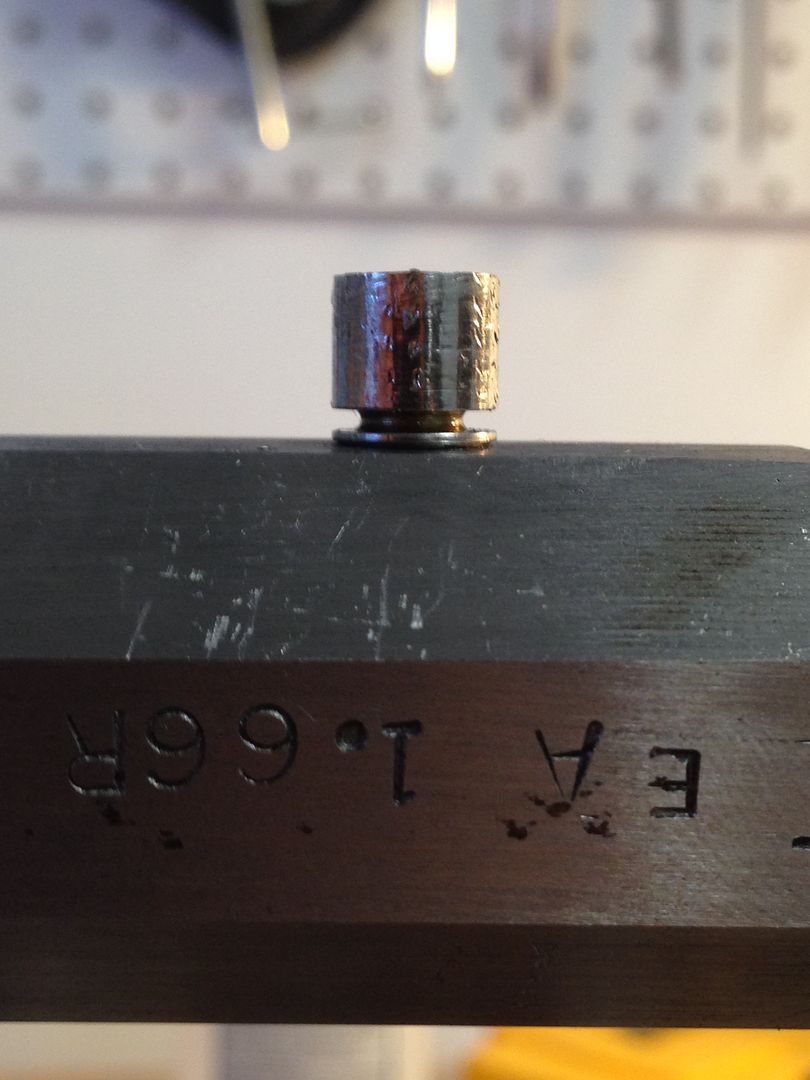

Okay, I'm working on my second build and installing a white lightnin touchhole liner from Jim Chambers (not the TOW version). So far I've drilled and tap the hole and slightly countersunk for the shoulder using an 82 degree countersink as indicated on the directions from Jim Chambers. My question is...did I countersink it enough or does it need more?

Here are some pics:

As always, thanks!

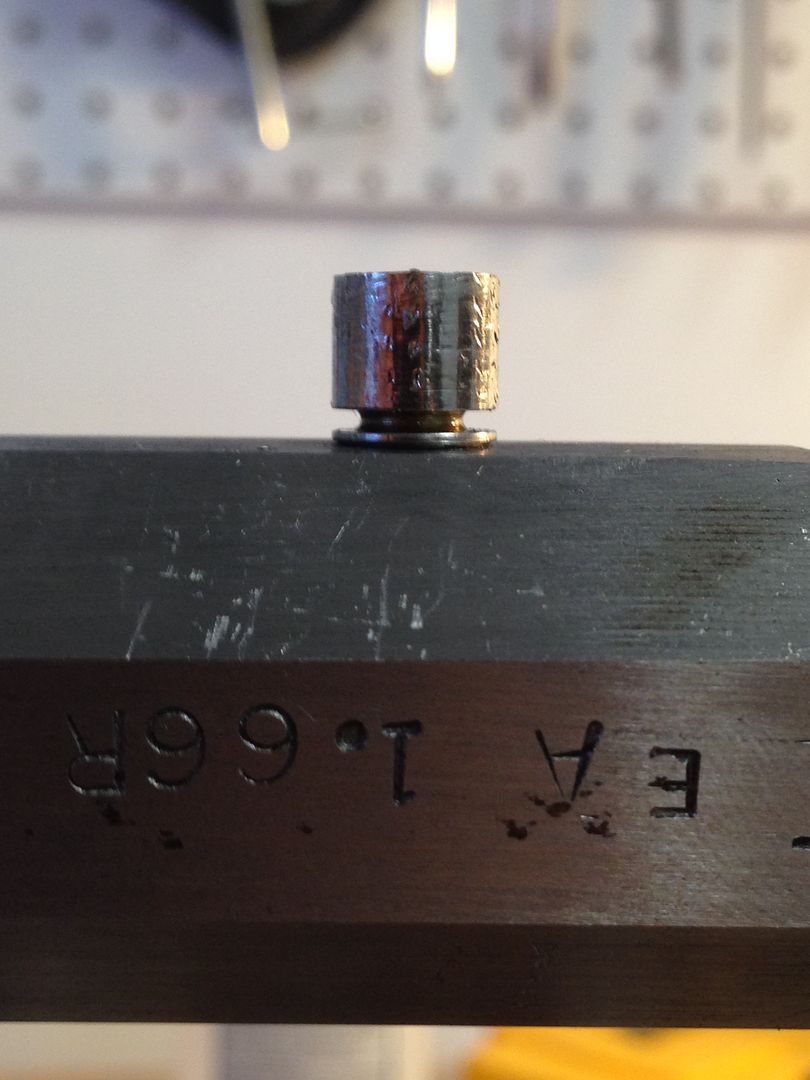

Here are some pics:

As always, thanks!