I am building my first rifle, a Tennessee/Southern Mountain Rifle. Does anybody have any tips on measuring and drilling the stock and lugs for the pins? I would appreciate any tips, as this appears to be a very precise task. There isn't a lot of wood between the bottom of the barrel and the top of the ramrod channel.

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips For Drilling and Pinning Barrel Lugs

- Thread starter jcline

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It looks like it is a daunting task, but after you do a couple it will seem easy. I use a set of calipers with long tips to measure the distance from the bottom of the ramrod pipe to the point where I want to drill the hole. Then I put the ramrod pipe in place in the forestock, and use the calipers to find the point where I want to drill the hole. It is easiest to drill the hole while the forestock is still squared off. Some precarves come this way. If your forestock is already rounded off, it is harder to keep the stock square and the drill has a tendency to wander. Zonie posted a message some time ago that showed a jig that he made to keep the stock square, but I don't remember what he used. Be sure to put a block of wood on the underside of the forestock when you drill to keep the wood from chipping out when you break through with the drill bit. Dive in, it isn't as hard as it looks.

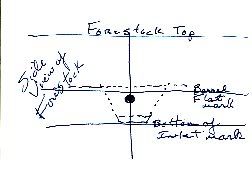

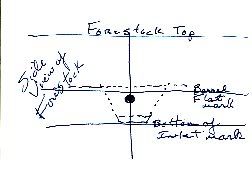

Here's a picture of how I measure it:

Here's a picture of how I measure it:

I place a metal straight edge over the top of the stock above barrel channel and use calipers to measure to the depth to the bottom of the barrel channel. Then I move the calipers to the outside of the stock and use the straight edge still in its current location to keep the calipers square and mark the bottom of the channel on the side of the stock. That is the upper limit of drill space. Then I measure down from this line the depth of the web at this point. That gives me the lower limit of drill space. Then it is a simple matter to drill between the "lines".

After installing and inletting for the underlug.

I just clamp the rifle in a wood vice. Mark the top of the barrel with a marker, take the barrel out of the stock, measure from the mark to where I want the hole to go. Take that mesurement and

Mark the stock with a pin hole, put the barrel back in the stock, clamp it in a drill press and level it up.

Then 'Drill-R' Just go easy and if it don't feel or look right, back off and check it. If you use a 1/16" drill bit, just use a small ammount of pressure.

If it is a little off use a toothpick with a little wood glue to fill the hole and try again.

You will know where you need to go, either up or down after the first time.

Remember this is only the first set of "blind holes" you are going to have to drill.

After these you still have the ramrod thimbles to install. I use the same techneque for both.

Regards

Mike

I just clamp the rifle in a wood vice. Mark the top of the barrel with a marker, take the barrel out of the stock, measure from the mark to where I want the hole to go. Take that mesurement and

Mark the stock with a pin hole, put the barrel back in the stock, clamp it in a drill press and level it up.

Then 'Drill-R' Just go easy and if it don't feel or look right, back off and check it. If you use a 1/16" drill bit, just use a small ammount of pressure.

If it is a little off use a toothpick with a little wood glue to fill the hole and try again.

You will know where you need to go, either up or down after the first time.

Remember this is only the first set of "blind holes" you are going to have to drill.

After these you still have the ramrod thimbles to install. I use the same techneque for both.

Regards

Mike

bioprof said:It looks like it is a daunting task, but after you do a couple it will seem easy. I use a set of calipers with long tips to measure the distance from the bottom of the ramrod pipe to the point where I want to drill the hole. Then I put the ramrod pipe in place in the forestock, and use the calipers to find the point where I want to drill the hole. It is easiest to drill the hole while the forestock is still squared off. Some precarves come this way. If your forestock is already rounded off, it is harder to keep the stock square and the drill has a tendency to wander. Zonie posted a message some time ago that showed a jig that he made to keep the stock square, but I don't remember what he used. Be sure to put a block of wood on the underside of the forestock when you drill to keep the wood from chipping out when you break through with the drill bit. Dive in, it isn't as hard as it looks.

Here's a picture of how I measure it:

Oops, I thought you were asking about drilling holes to install ramrod pipes. My mistake.

bioprof said:bioprof said:It looks like it is a daunting task, but after you do a couple it will seem easy. I use a set of calipers with long tips to measure the distance from the bottom of the ramrod pipe to the point where I want to drill the hole. Then I put the ramrod pipe in place in the forestock, and use the calipers to find the point where I want to drill the hole. It is easiest to drill the hole while the forestock is still squared off. Some precarves come this way. If your forestock is already rounded off, it is harder to keep the stock square and the drill has a tendency to wander. Zonie posted a message some time ago that showed a jig that he made to keep the stock square, but I don't remember what he used. Be sure to put a block of wood on the underside of the forestock when you drill to keep the wood from chipping out when you break through with the drill bit. Dive in, it isn't as hard as it looks.

Here's a picture of how I measure it:

Oops, I thought you were asking about drilling holes to install ramrod pipes. My mistake.

No problem, that answers that question.

Guest

If you have a drill press, this is how i do it. Take the barrel out of the stock and lay it on the drill press table on it's side and line up the lug with the bit. Clamp a piece of angle iron on the table against the top flat (which is now on the side) so that you can push the barrel up against the angle iron and the drill bit will be right on the lug. Then, mark the front and back edge locations of the lug on the side of the stock, put the barrel back in the stock, put the rifle on the drill press table on it's side with the top flat against the angle iron, line up the drill bit in between the two lines that indicate the location of the lug and drill the hole. Be sure that the top flat of the barrel is snug and flat against the angle iron. This ensures that the hole will come out in the right place. If the barrel is canted a bit the hole will come out either high or low on the other side of the stock. Don't forget to slot the hole in the lug afterwards.

Cody

P.S. if you are useing a tappered of swamped barrel the angle iron will have to be adjusted for each lug.

Cody

P.S. if you are useing a tappered of swamped barrel the angle iron will have to be adjusted for each lug.

I suggest you invest in a drilling jig or make one. I think Cain's Outdoors has them for ? $39. or something like that. I made mine years ago & it works very similar to the one they sell now. Keeps ya from having to plug a bunch of holes that don't look too good in the end.

Here is a couple of photos to show you what a homemade jig looks like. (Note the barrel tennon is not yet cut for the tennon, just showing you how the jig is put to the forestock)

I inlet the underlugs so they just barely clear the inlet. Put a depth gauge on the top of the forestock & measure to the top of the inlet for the Barrel Bottom flat. Take the gauge out & lay it on the outside of the forestock & mark the bottom of the depth gauge on the forestock

Then go back in same way with depth gauge & drop it down into the underlug inlet to the bottom of the inlet. Take the gauge back outside & mark the bottom of the depth gauge again... You now have 2 lines on the forestock.

Now I take a square & I mark a line across the top of the forestock that is in the Center of the tennon inlet. Now go down the sides with the square & mark a verticle line doen the forestock, this will be the center of the underlug inlet on the outside of the forestock. Take a centerpunch & ON that verticle tennon centerline, go just below the top mark you made on the underlug inlet.

This gives you a little leeway in case you are a little high, low, left or right. Then I take a centerpunch & make a small dent in each side of the forestock ON the dot you made on the verticle line, to align the drill jig to & to keep the bit from walking.

Put the barrel back in. I drill TO the lug & just mark it with the drill, turn drill jig around & drill the other way. Remove the barrel & now drill back in & make the holes meet.

Now I drill the tennon in the drill press & drill the pin hole.

Put the barrel back in & see if they allign & remove barrel, relieve it where it needs releived & give it about 1/32" slot on each side of the hole for shrinkage or swelling of the stock in a humidity change. End result is a elongated hole about 1/16" dia.

This is just one of Many ways of doing this building task.

If it is a straight barrel you should be able to easily have all the holes in a straight line down the forestock. On a swamped barrel you have to adjust each hole a little to get them lined up & it is a little more difficult. Some don't care if they are lined up, some do. If you cut molding on the forestock, it looks better if they are all lined up the same.

Note: DO NOT pressure the drill bit, as it will bow & your holes will not align...... Use a new bit & take your time..........

Also you may want to take a scrap piece 2" x 2" about 10" long, cut a slot in it about 3/4" deep the length of it, mark some practice holes & practice this before doing it on the stock. :thumbsup:

Here is a couple of photos to show you what a homemade jig looks like. (Note the barrel tennon is not yet cut for the tennon, just showing you how the jig is put to the forestock)

I inlet the underlugs so they just barely clear the inlet. Put a depth gauge on the top of the forestock & measure to the top of the inlet for the Barrel Bottom flat. Take the gauge out & lay it on the outside of the forestock & mark the bottom of the depth gauge on the forestock

Then go back in same way with depth gauge & drop it down into the underlug inlet to the bottom of the inlet. Take the gauge back outside & mark the bottom of the depth gauge again... You now have 2 lines on the forestock.

Now I take a square & I mark a line across the top of the forestock that is in the Center of the tennon inlet. Now go down the sides with the square & mark a verticle line doen the forestock, this will be the center of the underlug inlet on the outside of the forestock. Take a centerpunch & ON that verticle tennon centerline, go just below the top mark you made on the underlug inlet.

This gives you a little leeway in case you are a little high, low, left or right. Then I take a centerpunch & make a small dent in each side of the forestock ON the dot you made on the verticle line, to align the drill jig to & to keep the bit from walking.

Put the barrel back in. I drill TO the lug & just mark it with the drill, turn drill jig around & drill the other way. Remove the barrel & now drill back in & make the holes meet.

Now I drill the tennon in the drill press & drill the pin hole.

Put the barrel back in & see if they allign & remove barrel, relieve it where it needs releived & give it about 1/32" slot on each side of the hole for shrinkage or swelling of the stock in a humidity change. End result is a elongated hole about 1/16" dia.

This is just one of Many ways of doing this building task.

If it is a straight barrel you should be able to easily have all the holes in a straight line down the forestock. On a swamped barrel you have to adjust each hole a little to get them lined up & it is a little more difficult. Some don't care if they are lined up, some do. If you cut molding on the forestock, it looks better if they are all lined up the same.

Note: DO NOT pressure the drill bit, as it will bow & your holes will not align...... Use a new bit & take your time..........

Also you may want to take a scrap piece 2" x 2" about 10" long, cut a slot in it about 3/4" deep the length of it, mark some practice holes & practice this before doing it on the stock. :thumbsup:

rich pierce

70 Cal.

you've got lots of good advice there. The angle iron is the ticket if you can't get a good jig made.

If you have a precarve that is rounded, you will do well to take a block of hardwood and cut out a U-shaped piece that fits the forestock and slide it on. You can shim with cardboard etc till it's tight. Then you have a flat surface to drill.

If you have a precarve that is rounded, you will do well to take a block of hardwood and cut out a U-shaped piece that fits the forestock and slide it on. You can shim with cardboard etc till it's tight. Then you have a flat surface to drill.

Similar threads

- Replies

- 43

- Views

- 2K

- Replies

- 35

- Views

- 3K