-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spiller & Burr

- Thread starter jaxenro

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- May 28, 2006

- Messages

- 1,692

- Reaction score

- 14

I had a Spiller awhile back..it shot great with 18-25 grains FFF. The grip frame was just too small for me...no distance between the triggerguard and middle finger. It only took about 12 rounds of firing to rub a Beautiful Blister on the middle finger. I would say that I have mid sized hands.....

Other than that it was a great pistol

Other than that it was a great pistol

I had one that I built from a Dixie kit years ago. It isn't the most graceful looking pistol, but very interesting history behind it. It is one of the few brass frame revolvers on the market that is close to being historically correct. I think Ralph Walker might have published a chapter in his book on building one of these from a kit.

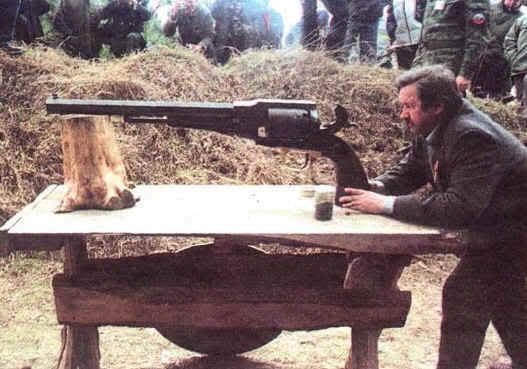

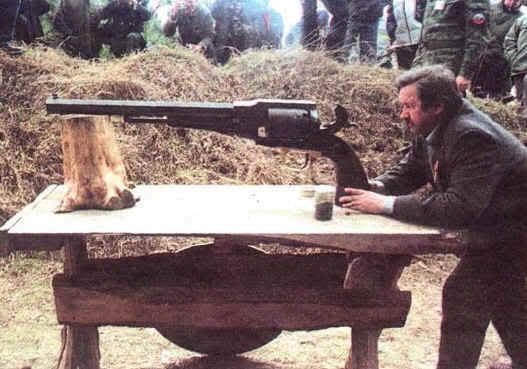

I have a Spiller & Burr that I built from a kit.

It turned out very nice if I do say so myself. :grin:

I haven't shot it a lot but it did work with a 18 grain load of FFFg and .375 dia roundballs.

I didn't notice any problem with the grip and trigger guard but these .36's don't kick very hard. Maybe if my hand was larger I might have noticed it?

The only thing I consider as a weak point is the screw that connects the ram to the loading lever is a very small diameter screw and it doesn't look like it could take a real heavy load without sheering. Because of this I wouldn't consider using a pistol bullet in the gun but it does seem to work alright for loading roundballs.

Another thing that leaves a bit to be desired is the cylinder axle release. This is a small screw located on the left side of the frame. To remove the cylinder bolt, the screw is turned 180 degrees (only) which aligns a notch in the screw with the axel to allow the axle's removal.

If this screw isn't positioned correctly, the cylinder axle (to which the loading lever is attached) may pull loose from the frame.

The Spiller & Burr has an interesting history.

As you may know it is patterned after the .36 cal Whitney (a steel framed revolver).

When Spiller & Burr contracted with the Confederacy to make 15,000 pistols the contract very clearly says the gun will be "substantially of the Colt's pattern".

The answer to this substitution of a Whitney Copy for a Colt copy seems to be that another company called the Robinson Revolver Factory in Richmond, Virginia had tooled up to produce a copy of the Whitney for sale to Virginia but never produced any of the pistols.

When Spiller & Burr established their company in Richmond. Virginia, they apparently bought the tooling and designs from Robinson however they never produced any known pistols at that location.

They moved the equipment to Atlanta, Georgia and produced about 700 pistols there.

Because they were so far behind in their delivery the Confederate Government bought them out lock, stock and barrel and moved the resulting company to Macon, Georgia where over 600 pistols were manufactured.

The total number of Spiller & Burr pistols during the war was about 1,400 or less than 10 percent of the number the original contract specified.

zonie

It turned out very nice if I do say so myself. :grin:

I haven't shot it a lot but it did work with a 18 grain load of FFFg and .375 dia roundballs.

I didn't notice any problem with the grip and trigger guard but these .36's don't kick very hard. Maybe if my hand was larger I might have noticed it?

The only thing I consider as a weak point is the screw that connects the ram to the loading lever is a very small diameter screw and it doesn't look like it could take a real heavy load without sheering. Because of this I wouldn't consider using a pistol bullet in the gun but it does seem to work alright for loading roundballs.

Another thing that leaves a bit to be desired is the cylinder axle release. This is a small screw located on the left side of the frame. To remove the cylinder bolt, the screw is turned 180 degrees (only) which aligns a notch in the screw with the axel to allow the axle's removal.

If this screw isn't positioned correctly, the cylinder axle (to which the loading lever is attached) may pull loose from the frame.

The Spiller & Burr has an interesting history.

As you may know it is patterned after the .36 cal Whitney (a steel framed revolver).

When Spiller & Burr contracted with the Confederacy to make 15,000 pistols the contract very clearly says the gun will be "substantially of the Colt's pattern".

The answer to this substitution of a Whitney Copy for a Colt copy seems to be that another company called the Robinson Revolver Factory in Richmond, Virginia had tooled up to produce a copy of the Whitney for sale to Virginia but never produced any of the pistols.

When Spiller & Burr established their company in Richmond. Virginia, they apparently bought the tooling and designs from Robinson however they never produced any known pistols at that location.

They moved the equipment to Atlanta, Georgia and produced about 700 pistols there.

Because they were so far behind in their delivery the Confederate Government bought them out lock, stock and barrel and moved the resulting company to Macon, Georgia where over 600 pistols were manufactured.

The total number of Spiller & Burr pistols during the war was about 1,400 or less than 10 percent of the number the original contract specified.

zonie

- Joined

- May 28, 2006

- Messages

- 1,692

- Reaction score

- 14

Zonie....you know all the good details! We are so glad you are THE MODERATOR!!! :thumbsup:

Guest

- Joined

- May 28, 2006

- Messages

- 1,692

- Reaction score

- 14

AIRBORNE.... That sure is a SWEETIE!

makes me wish I still had mine....sigh...

but these big ole busted up welder knuckles just came in contact with the trigger guard every time I shot her....sigh...( the gun that is...the ole woman is still ALIVE!!!)

sure was a nice ole .36 though.......but..I had to git a BIGGER GUN!!!

makes me wish I still had mine....sigh...

but these big ole busted up welder knuckles just came in contact with the trigger guard every time I shot her....sigh...( the gun that is...the ole woman is still ALIVE!!!)

sure was a nice ole .36 though.......but..I had to git a BIGGER GUN!!!

...and if you want to be super authentic, engrave a shallow spiral groove around the cylinder, front to back. The originals had this but it was the result of the iron bar that was to be the cylinder being twisted in the supposition that increased the strength of the finished cylinder. The things us guys down South thought up! :wink:

I sent for one of the kits, figured for $165 you can't really go wrong. Any idea how they were finished? I understand the first model had silver plated frames but the second model was plain brass and the Dixie kit is more like the second model? Were the other parts rust blued, charcoal blued, or what? Sounds like they were somewhat roughly finished and were made in three different cities, possibly by some different men with different degrees of finish and polish?

According to "FLAYDERMAN'S GUIDE" The Spiller and Burr was had a blued finish and brass frame.

I seriously doubt that any of them were silver plated because not only did the South need every cent they had for more important things but the Contract for the guns production was made long before the first gun was built. That would make having things like silver plating unnecessary because there would be no need for a super fine looking pistol to make the sale.

Of course Flayderman doesn't describe what kind of bluing was used but either rust or heat bluing would have been possible.

As to the guns being somewhat roughly finished, many of the Southern pistol factories used slave labor to file, finish and assemble their guns so it is fair to say there weren't many examples of any of them made with a high degree of craftsmanship or polish.

That is not to say they were rough unfinished guns but Colt Pythons they were not.

Oh! As your going to get one of these guns you might be interested in another little item of note. If your gun is like mine, it won't have any cylinder safety stops machined into the rear of the cylinder.

Flaydermans says ".36 caliber, 6-shot round cylinder with six stop slots and twist design visible on the surface...Safety slots between nipples on rear of cylinder..."

Going on a bit speaking of the early production guns he says "...Other quickly noticeable features are...the absence of the hammer safety rests/slots on the cylinder..." so, even without these slots the gun is still "correct". :grin:

As for the "twist design" this is referring to some barely visible spiral grooves which can be seen on the outside of the cylinder.

These grooves were the result of twisting the hot material the cylinders were made from, the idea being that twisting the iron would give it greater strength.

Because this twisting created a spiral pattern and I didn't have any references to show how tightly the spiral looks I didn't even try to duplicate it on the gun I built.

Have fun.

zonie

I seriously doubt that any of them were silver plated because not only did the South need every cent they had for more important things but the Contract for the guns production was made long before the first gun was built. That would make having things like silver plating unnecessary because there would be no need for a super fine looking pistol to make the sale.

Of course Flayderman doesn't describe what kind of bluing was used but either rust or heat bluing would have been possible.

As to the guns being somewhat roughly finished, many of the Southern pistol factories used slave labor to file, finish and assemble their guns so it is fair to say there weren't many examples of any of them made with a high degree of craftsmanship or polish.

That is not to say they were rough unfinished guns but Colt Pythons they were not.

Oh! As your going to get one of these guns you might be interested in another little item of note. If your gun is like mine, it won't have any cylinder safety stops machined into the rear of the cylinder.

Flaydermans says ".36 caliber, 6-shot round cylinder with six stop slots and twist design visible on the surface...Safety slots between nipples on rear of cylinder..."

Going on a bit speaking of the early production guns he says "...Other quickly noticeable features are...the absence of the hammer safety rests/slots on the cylinder..." so, even without these slots the gun is still "correct". :grin:

As for the "twist design" this is referring to some barely visible spiral grooves which can be seen on the outside of the cylinder.

These grooves were the result of twisting the hot material the cylinders were made from, the idea being that twisting the iron would give it greater strength.

Because this twisting created a spiral pattern and I didn't have any references to show how tightly the spiral looks I didn't even try to duplicate it on the gun I built.

Have fun.

zonie

Thanks - I got the information on silver plating from this site:

[url] http://www.csarmory.org/spiller/spiller.html[/url]

I think the idea of the twist was to not have the weld lines running parallel with the cylinder chambers.

[url] http://www.csarmory.org/spiller/spiller.html[/url]

I think the idea of the twist was to not have the weld lines running parallel with the cylinder chambers.

Last edited by a moderator:

Ah yes. The old Foot in Mouth disease. :redface:

"Open Mouth, Insert Foot, chew vigorously."

Of the several references that I looked at, they didn't say a word about the silver plating.

In the book CONFEDERATE HANDGUNS by William A. Albaugh, III, Hugh Benet, Jr. and Edward N. Simmons, on page 64, writing about the agreement between Spiller & Burr and the Confederacy it says,

"...That only the best obtainable materials were to be used, but in the event steel for the cylinders and barrels could not be obtained it was agreed that iron of suitable good quality could be substituted. The lock frames were to be of good tough brass "properly electro-plated with silver." This is another startling dictate and reflects the impracticality that characterized the early days of the war."

zonie

"Open Mouth, Insert Foot, chew vigorously."

Of the several references that I looked at, they didn't say a word about the silver plating.

In the book CONFEDERATE HANDGUNS by William A. Albaugh, III, Hugh Benet, Jr. and Edward N. Simmons, on page 64, writing about the agreement between Spiller & Burr and the Confederacy it says,

"...That only the best obtainable materials were to be used, but in the event steel for the cylinders and barrels could not be obtained it was agreed that iron of suitable good quality could be substituted. The lock frames were to be of good tough brass "properly electro-plated with silver." This is another startling dictate and reflects the impracticality that characterized the early days of the war."

zonie

- Joined

- May 28, 2006

- Messages

- 1,692

- Reaction score

- 14

Yes!! Action shots of the building process Please! Want to see that sweetie come Alive!

...then shooting reports please....

...then shooting reports please....

jaxenro: If you post building pictures it would be best to post them in the Gun Builders Bench area of the forum.

Claude likes to keep the Pre Flint, Flintlock, Smoothbore, Percussion, etc forum areas for posts dealing with actually shooting guns and the successes, problems and questions that are involved with that activity.

The Gun Builders Bench isn't just for us nuts who build a lot of guns. It's for everyone.

zonie

Claude likes to keep the Pre Flint, Flintlock, Smoothbore, Percussion, etc forum areas for posts dealing with actually shooting guns and the successes, problems and questions that are involved with that activity.

The Gun Builders Bench isn't just for us nuts who build a lot of guns. It's for everyone.

zonie

Similar threads

Latest posts

-

-

Very stuck minie ball, tried everything having to pull the breech plug

- Latest: Philip Lebow

-

-

-

-

-

-