-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shooting bag build. How I do it.

- Thread starter jethro224

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well done and thanks for the tutorial and visuals which really help. :thumbsup: :hatsoff:

Dave

Dave

All that's left now is the hard part. You may have noticed that your new bag is inside out! Now you gotta turn that sucker. Push, pull, cuss, get 2 men and a boy to help, whatever it takes, you'll get it eventually. On really tough bags I have used the handle of a sledge hammer with the head on the ground to push up on the bag while I pull down.

I just did my first bag using some cheap leather from a craft shop. The leather was really too thick, but I put it together anyway. Only way I could find to reverse this heavy leather was to submerge the bag in water for a couple of minutes and then it reversed rather easily. Dried with no apparent ill effects.

Brokennock

Cannon

I'm sure there is some obvious reason that will give me one of those, "well, duh," moments, but, why seen on flap and not have a one piece back and flap?

- Joined

- Jan 3, 2004

- Messages

- 14,767

- Reaction score

- 313

I've tried both, and the one piece tends to flop open when you forget to fasten it or don't have time. Spills stuff all over tarnation if you're moving. Meanwhile the sewn variety wants to stay closed. You can get by quite well without a fastener with many leathers. You can tell my choice, cuzz it's been quite a while since I made another one-piece.

The bags I've made using fairly heavy oil-tanned leather and a one-piece back and flap have the problem BrownBear described. My main two bags, though, both one-piece, one a single and one a double, and which have gotten a lot of use over many years, are made of thinner pigskin. Neither of those has the problem, the flap behaves very well. I decided the thickness and stiffness of the leather was the problem, not the design.

A very good tutorial, Jethro224.

Spence

A very good tutorial, Jethro224.

Spence

Good job Jethro Thanks for taking the time to post your effort. :hatsoff: I have the same style bag I made from the TC Albert book pattern. It's a good bag and has served me well...If I build another one of the same style I will enlarge the pattern a little to make it easier to get my hand into. I seem to have that problem with every bag I build. :idunno: Maybe I should put my hands on a diet. :hmm: Great job Thanks again for posting. :thumbsup:

- Joined

- Jan 3, 2004

- Messages

- 14,767

- Reaction score

- 313

smo said:...enlarge the pattern a little to make it easier to get my hand into.

I prefer smaller bags, but you've nailed the bottom line. They have to be big enough to get your hand in, grab something, then pull it out without hanging.

- Joined

- Jun 12, 2005

- Messages

- 7,970

- Reaction score

- 964

cool post ... count me in on the notion of making it permanent ...

your new bag looks great!

(by the way, there should be one bag for each firearm. this way, all the 'stuff' you need to shoot that particular gun is right there; hand the bag with the gun and you're all set. also, of course, one horn with each bag with each gun)

your new bag looks great!

(by the way, there should be one bag for each firearm. this way, all the 'stuff' you need to shoot that particular gun is right there; hand the bag with the gun and you're all set. also, of course, one horn with each bag with each gun)

gunsmithscott

32 Cal.

- Joined

- Mar 26, 2009

- Messages

- 30

- Reaction score

- 0

Well done Jethro. Bring it top the frolic and I will give ya 5 dollar cash money fer it!! :grin:

White Oak

40 Cal.

Jethro,

Many thanks for posting this. I am just finishing up my first attempt at a bag and I was pretty proud of it until I saw yours. I picked up a lot of great info here to apply to my next attempt. I too would like to see this post hang around for future reference. Thanks a million for sharing! :bow: Great post!

Take care,

Ed

Many thanks for posting this. I am just finishing up my first attempt at a bag and I was pretty proud of it until I saw yours. I picked up a lot of great info here to apply to my next attempt. I too would like to see this post hang around for future reference. Thanks a million for sharing! :bow: Great post!

Take care,

Ed

- Joined

- Jan 31, 2016

- Messages

- 1,296

- Reaction score

- 1

Jethro makes leather crafting look a lot easier than it actually is...

plus, I am getting my very own :blah:

plus, I am getting my very own :blah:

- Joined

- May 6, 2014

- Messages

- 16,892

- Reaction score

- 15,309

Jethro224 said:Are y'all ready to finish this project?

Here we go.

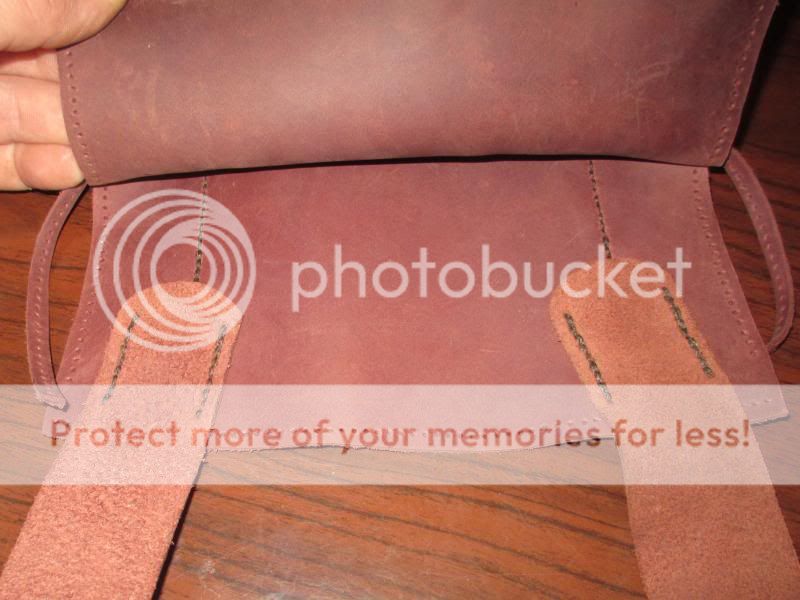

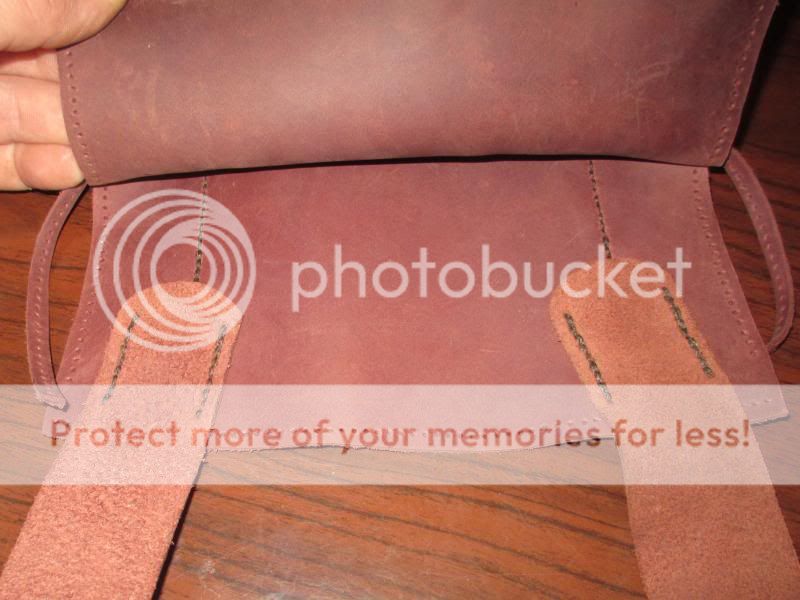

Now we gotta sew them strap ends in while it's still easy to get to 'em. This is probably the highest stressed area of the whole thing so I double stitch the entire seams. Sew 'em on with the finished side against the finished side of the back panel.

Almost done. We still need to cut the strap to length, put a buckle on, and punch a few holes for adjustment. I like the buckle on the back and a couple of holes shorter and longer than where I intend to buckle the strap. This bag gets a forged iron buckle made by Steve Baxter.

I use my hole puncher to make a slot about 3/4 inch long where the tongue of the buckle goes thru. They make a tool for this...

Just wanted to mention something you already know, but some others may not realize. The two pics above illustrate it nicely.

On your straps, you ran stitches along the length of the straps, but did not run them across to form either a "U" or Square/Rectangular "box." When I began sewing belts, bags, etc., etc.; I did not have a mentor to teach me and I thought that using a square or rectangular "box" of stitches would reinforce the stitching at these critical points and look better. I got away with this for quite some time, BUT I finally found out why it should not be done in high stress areas.

I did a nice "rectangle box" of stitching to hold the buckle on my 18th century waist belt I had made from 4-5 oz. vegetable tanned leather. The stitches going across or perpendicular to the length of the belt wound up weakening the leather and it failed at the edge furthest from the buckle and I had to replace the belt. Those "cross the length stitches" actually sort of sawed the belt leather in half. (Actually I re-sewed it for a younger lad with a smaller waist than mine. He got a belt for the price of a buckle and I learned a valuable lesson. Good deal for both of us.)

Gus

--------------------------------------------------------------------------------------------------------Artificer said:Jethro224 said:Are y'all ready to finish this project?

Here we go.

Now we gotta sew them strap ends in while it's still easy to get to 'em. This is probably the highest stressed area of the whole thing so I double stitch the entire seams. Sew 'em on with the finished side against the finished side of the back panel.

Almost done. We still need to cut the strap to length, put a buckle on, and punch a few holes for adjustment. I like the buckle on the back and a couple of holes shorter and longer than where I intend to buckle the strap. This bag gets a forged iron buckle made by Steve Baxter.

I use my hole puncher to make a slot about 3/4 inch long where the tongue of the buckle goes thru. They make a tool for this...

Just wanted to mention something you already know, but some others may not realize. The two pics above illustrate it nicely.

On your straps, you ran stitches along the length of the straps, but did not run them across to form either a "U" or Square/Rectangular "box." When I began sewing belts, bags, etc., etc.; I did not have a mentor to teach me and I thought that using a square or rectangular "box" of stitches would reinforce the stitching at these critical points and look better. I got away with this for quite some time, BUT I finally found out why it should not be done in high stress areas.

I did a nice "rectangle box" of stitching to hold the buckle on my 18th century waist belt I had made from 4-5 oz. vegetable tanned leather. The stitches going across or perpendicular to the length of the belt wound up weakening the leather and it failed at the edge furthest from the buckle and I had to replace the belt. Those "cross the length stitches" actually sort of sawed the belt leather in half. (Actually I re-sewed it for a younger lad with a smaller waist than mine. He got a belt for the price of a buckle and I learned a valuable lesson. Good deal for both of us.)

Gus

-------------Notice the straps are attached at an angle...NOT Straight! This relieves lots of stress -----------

Looking good Jethro!!

- Joined

- May 6, 2014

- Messages

- 16,892

- Reaction score

- 15,309

Good point. Attaching the straps at an angle not only makes a Shooting Pouch fit the body better, but keeps the straps from as much "twisting stress" that would cause a rectangular box stitching to wear out the leather even faster.

I got to the point where I always wanted to put the strap on the person and mark the position of the strap/s before I sewed it/them onto the pouch, so the strap/s would fit that individual better.

Gus

I got to the point where I always wanted to put the strap on the person and mark the position of the strap/s before I sewed it/them onto the pouch, so the strap/s would fit that individual better.

Gus

Similar threads

- Locked

- Replies

- 5

- Views

- 570

- Replies

- 3

- Views

- 443