Hi Jim,

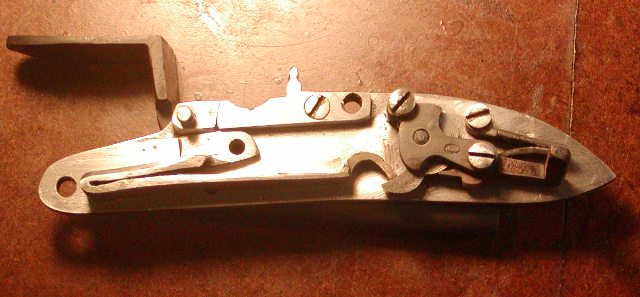

If you read any of my many posts about working on India-made guns, you will find that I have great respect for the workmen and their skills working under very primitive conditions and with simple tools. The culprits are the middlemen and the consumers who cannot or will not pay for good quality hand work. They perpetuate the race to the bottom. I have no doubt those skilled men could produce good quality work if given training, knowledge, good wages, and good working conditions. But there is another issue, Jim. You write frequently that many modern muzzleloader owners and shooters do not know what quality is or how good flint locks were made and perform. I am fully in agreement with you and further, these guns do nothing to improve that base of general knowledge. Some work pretty well but many do not. They perpetuate the notion that flintlocks were unreliable and military guns were crudely made. You and I both know that well designed and made flintlocks were incredibly reliable. We both know what it takes to achieve that. But those Indian makers are providing a diversity of products no American maker provides. For many folks, they are the only game in town other than custom made firearms, and they often don't want to pay the cost or wait for those. Anyway, my intent in this thread is to show some of the problems buyers will encounter with poorly made locks often on India-made guns and what to do about it. It is not cast them away but rather here is how to fix it.

dave