- Joined

- Nov 26, 2005

- Messages

- 5,018

- Reaction score

- 9,972

Hi Guys,

My apprentice, Maria, is the armorer for Warner's Extra-Continental Regiment, the Green Mountain Boys. After last weekend's event at Ethan Allen's homestead, she brought back repair work to the shop. A lock from a well used Miroku Brown Bess was tired and the frizzen loose and floppy. The trigger pull on the musket was a spongy 10 pounds. The next gun was an India made fusil de chasse that had a horrendously heavy trigger pull and simply did not spark or shoot very well. The third project was an India-made long land Brown Bess that also had a horrendous trigger pull and did not work very well. The owners all wanted to get the guns working before the Battle of Hubbardton event next weekend. It is instructive that the only gun still working flawlessly during tactical demonstrations on the final day of the event was Maria's fowler with a tuned high quality lock. Flintlocks are systems, meaning you can rarely correct one thing because when you do, you have to adjust or correct several more. Anyway, the Miroku lock was the best of the bunch but it needed help. One of the most serious issues is the half cock notch sticks out much further than the full cock notch.

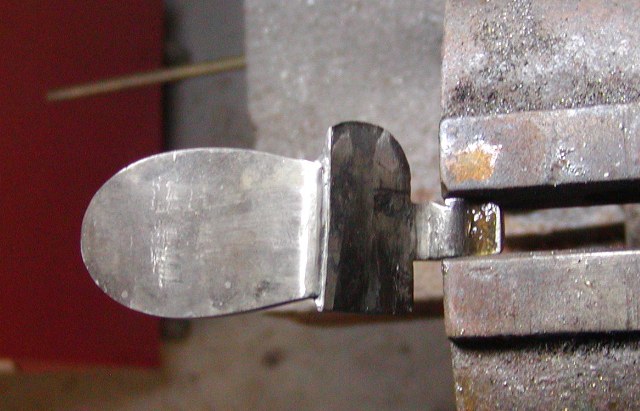

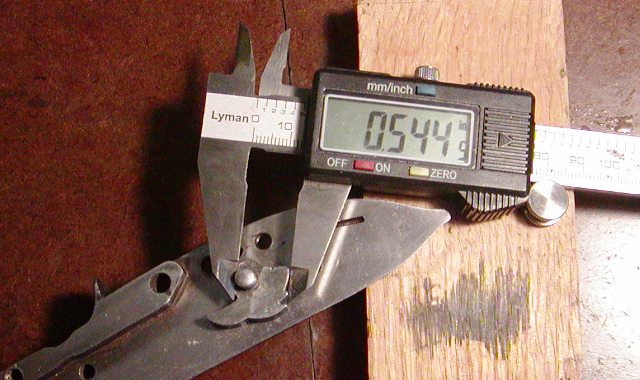

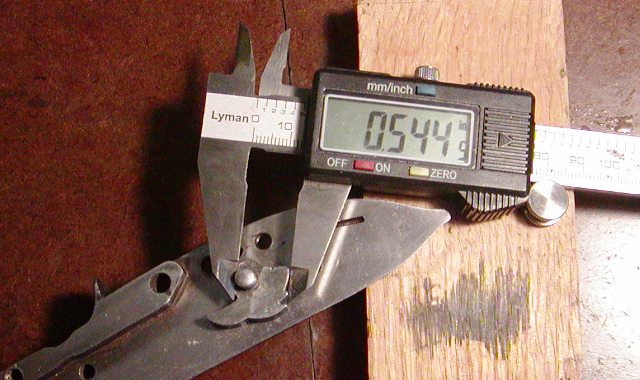

What that means is you cannot lighten the trigger pull very much because it is that trigger pull pressure that keeps the sear out of the half cock notch when the lock is fired. With a light trigger squeeze, the sear will easily drop back into the half cock notch when firing. This is the reason why set triggers require locks with fly detents. This Miroku lock cannot possibly work with a light trigger. We will take care of that by grinding down the lip of the halfcock notch and reconfiguring the tumbler notches as best we can. We welded steel on the sides of the toe of the worn frizzen to make it fit precisely into the slot between the lock plate and pan bridle. I made a new frizzen pivot screw that fits precisely. One reason for the mushy trigger pull was the hole for the sear screw was too large for the screw and the sear and bridle moved under pressure. We solved that by making a new sear screw on which there was a larger shoulder that fit in the bridle hole, then narrowed to fit the sear precisely, then narrowed again to make a shoulder for the threads so it tightened against the lock plate without pinching the bridle and sear. Everything fit well after our modifications and the components we changed are to be case hardened and tempered.

Now the other two projects. I am going to stop any narrative and just show photos. I am not sure what we will do to fix these problems. The first is the Bess and the second is the fusil.

dave

My apprentice, Maria, is the armorer for Warner's Extra-Continental Regiment, the Green Mountain Boys. After last weekend's event at Ethan Allen's homestead, she brought back repair work to the shop. A lock from a well used Miroku Brown Bess was tired and the frizzen loose and floppy. The trigger pull on the musket was a spongy 10 pounds. The next gun was an India made fusil de chasse that had a horrendously heavy trigger pull and simply did not spark or shoot very well. The third project was an India-made long land Brown Bess that also had a horrendous trigger pull and did not work very well. The owners all wanted to get the guns working before the Battle of Hubbardton event next weekend. It is instructive that the only gun still working flawlessly during tactical demonstrations on the final day of the event was Maria's fowler with a tuned high quality lock. Flintlocks are systems, meaning you can rarely correct one thing because when you do, you have to adjust or correct several more. Anyway, the Miroku lock was the best of the bunch but it needed help. One of the most serious issues is the half cock notch sticks out much further than the full cock notch.

What that means is you cannot lighten the trigger pull very much because it is that trigger pull pressure that keeps the sear out of the half cock notch when the lock is fired. With a light trigger squeeze, the sear will easily drop back into the half cock notch when firing. This is the reason why set triggers require locks with fly detents. This Miroku lock cannot possibly work with a light trigger. We will take care of that by grinding down the lip of the halfcock notch and reconfiguring the tumbler notches as best we can. We welded steel on the sides of the toe of the worn frizzen to make it fit precisely into the slot between the lock plate and pan bridle. I made a new frizzen pivot screw that fits precisely. One reason for the mushy trigger pull was the hole for the sear screw was too large for the screw and the sear and bridle moved under pressure. We solved that by making a new sear screw on which there was a larger shoulder that fit in the bridle hole, then narrowed to fit the sear precisely, then narrowed again to make a shoulder for the threads so it tightened against the lock plate without pinching the bridle and sear. Everything fit well after our modifications and the components we changed are to be case hardened and tempered.

Now the other two projects. I am going to stop any narrative and just show photos. I am not sure what we will do to fix these problems. The first is the Bess and the second is the fusil.

dave