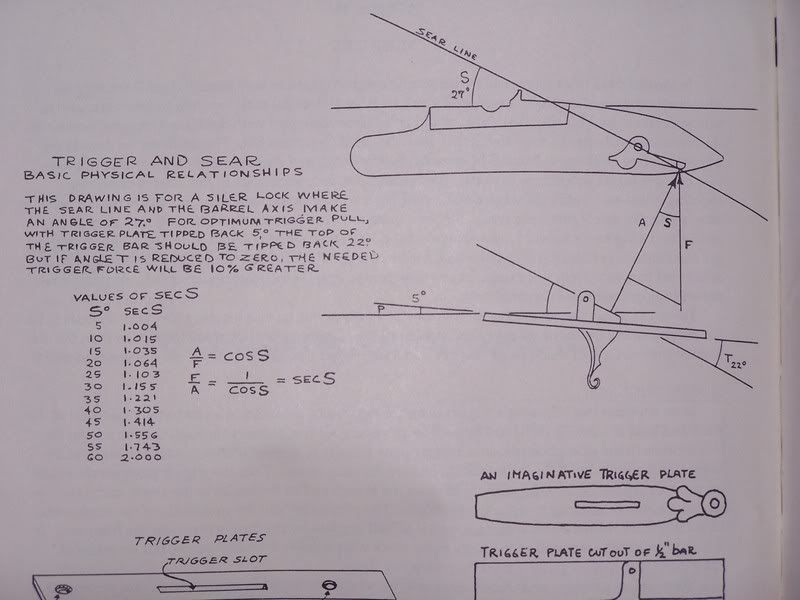

Trigger said:Not quite Fitter. Harddog is repeating a mantra he read in a book. I was giving a set of general rules for designing a good trigger. They overlap, but I can use his mantra to build a bad trigger: that is my whole point.

Well,

There you go! You made a serious faux pas for message boards. You assume you have some knowledge about my abilties, knowledge and background just by reading a couple of messages and in actuality you don't. Not by a long shot.

I was definately not repeating a mantra based on something that I read in a book. I have not even read any of the books, but do answer messages from confused guys asking questions on various message boards about material in "those" books. I believe I was scratch building muzzleloaaders before any of the building books were even published, although Buchle's book was published early on.

BTW, there is no way that you can install a simple trigger based on my original message and end up with a "bad" trigger. Only by changing the content of what I stated, adding extraneous elements or projecting your own misunderstanding of what I originally said into the mix will you end up with a bad trigger installation.

You have also suggested that I can not read, have a low ability for comprehension of the written word and off handedly denigrated my math abilities. In a round about way you have also questioned my knowledge of muzzleloader building. Shame, Shame, not something that is accepted behavior on message boards. (Please see my last message for a little about my background.)

While I don't claim to be the best muzzleloader builder there ever was, I have been scratch building muzzleloaders since the early 1960's. Didn't like and sent back a kit I ordered from Dixie Gun Works back in 1959 or 1960 and have scratch built ever since. Up until I sufferred a rotator cuff injury in my shoulder 4-5 years ago I averaged 6-7 guns per year. (You do the math) While I am not going to send you a gun of my make with a properly installed simple trigger for you to try, if you actually question my abilities as a builder I think I can scrounge up a few pictures of past projects although I never really saw the need to photograph most of my work. At the moment I have four build projects on my bench, but I am moving slow because of my shoulder problems.

My actual knowledge about the proper way to install a simple trigger for optimal efficiency comes from figuring it out for myself early on and refining it over the years.

Remember, someone disagreeing with you on a message board does not mean they are arguing, it just means they are stating a different point of view. If there were no differing points of view on a subject like this then each question would only require one answer. Never any need to denigrate, belittle or make wrong assumptions about another responder.

Randy Hedden