robinghewitt

62 Cal.

- Joined

- Jun 26, 2004

- Messages

- 2,605

- Reaction score

- 19

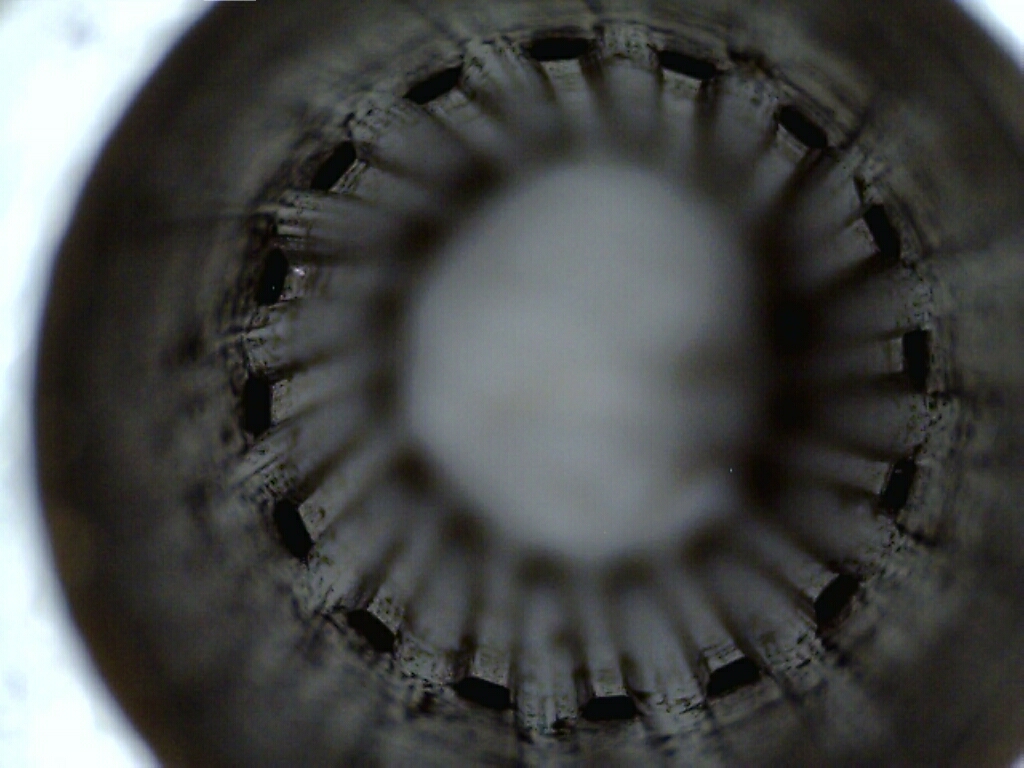

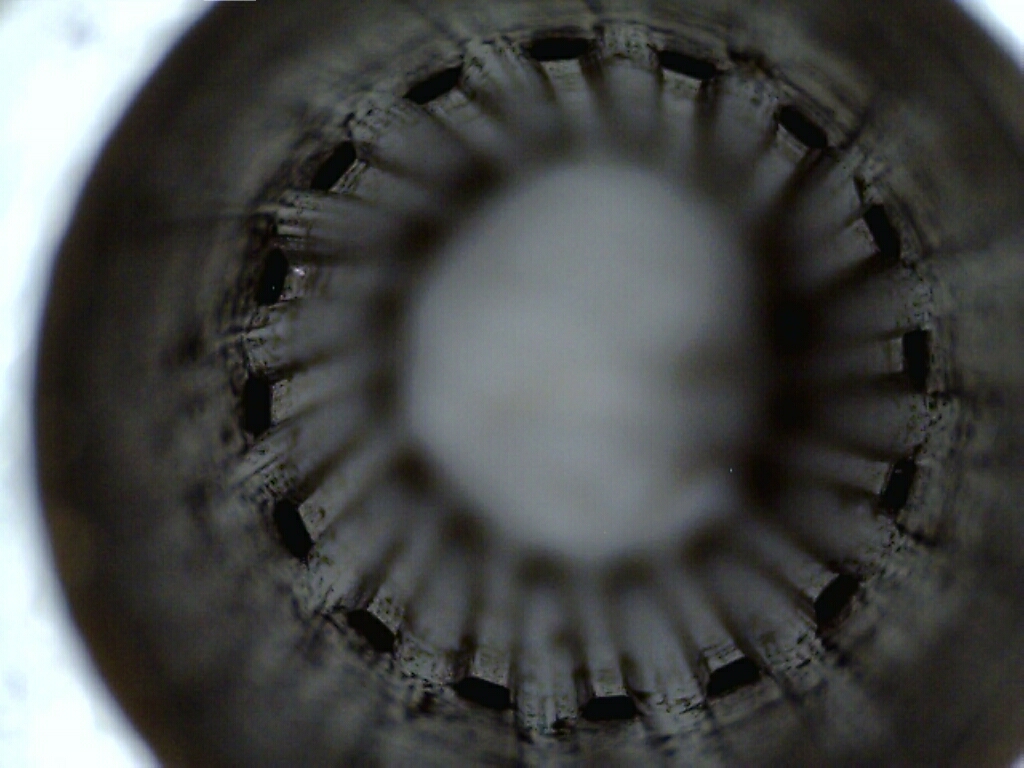

Got me a Harpers Ferry Hall in original 1826 flint

Everyone who photographs a Hall goes straight for the pop up breeching, so I thought I'd be different :thumbsup: :rotf:

Everyone who photographs a Hall goes straight for the pop up breeching, so I thought I'd be different :thumbsup: :rotf: