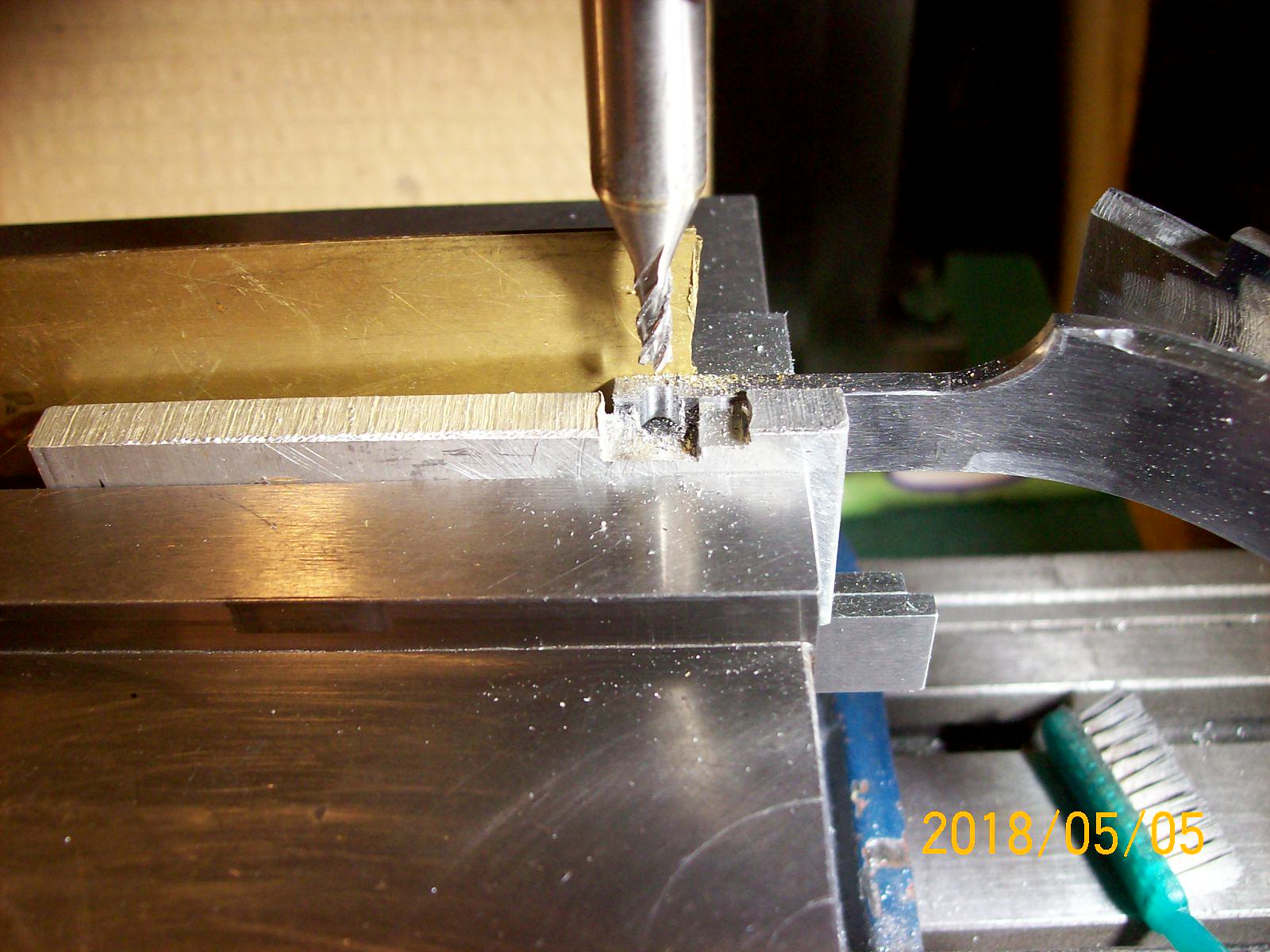

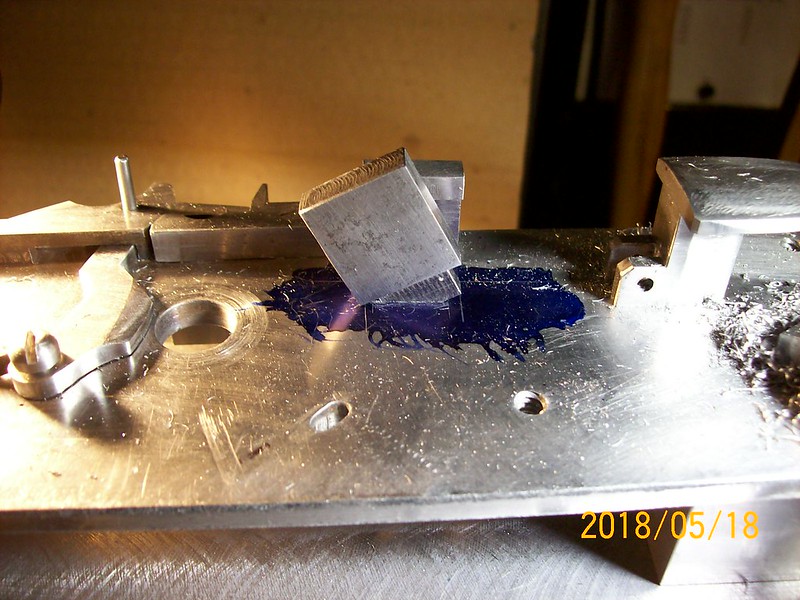

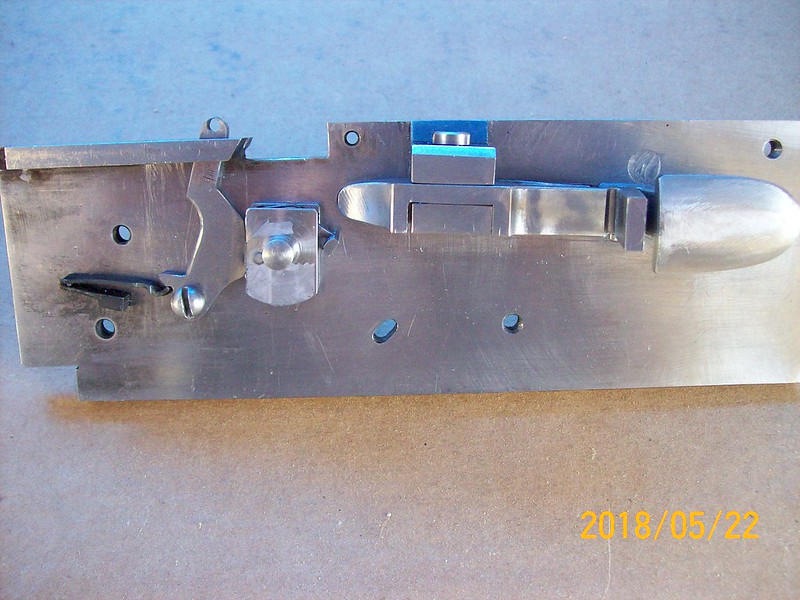

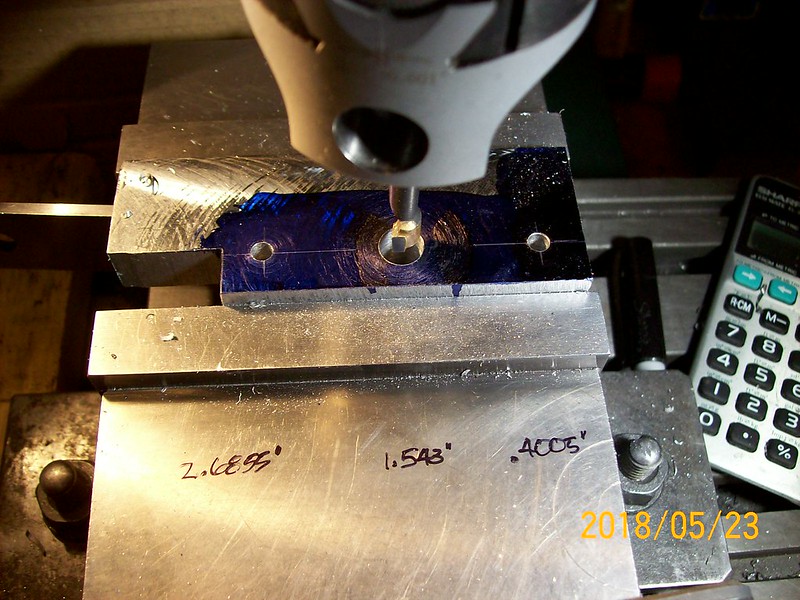

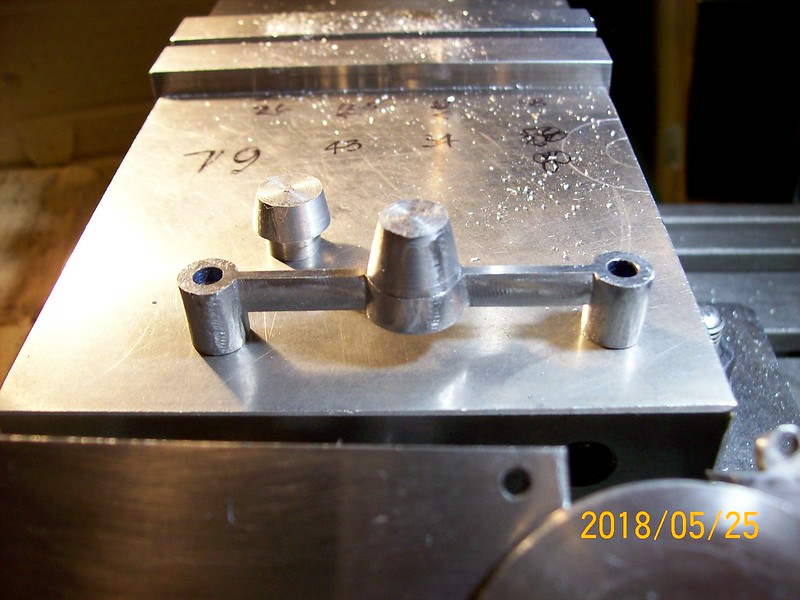

Progress photos - mainspring support riveted thru lockplate and top of the support riveted on after (side view). The sear will pivot inside this part.

100_0592

100_0592

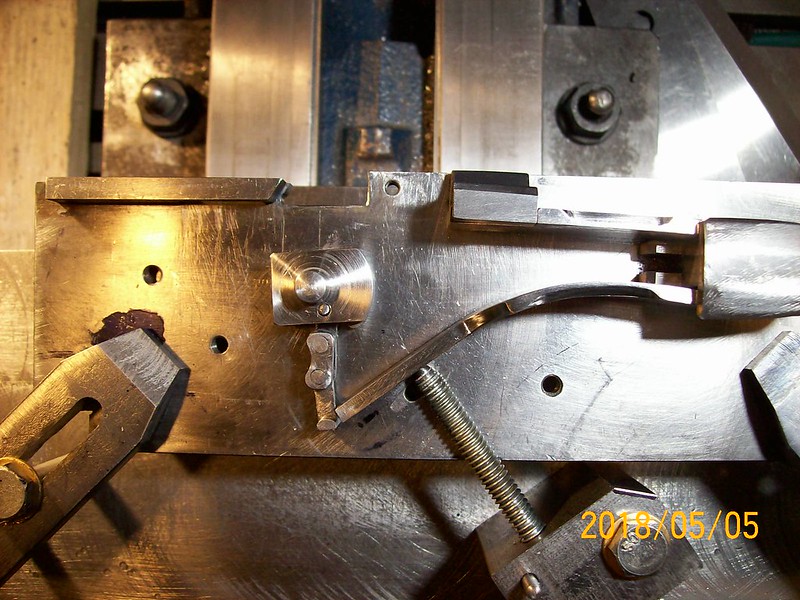

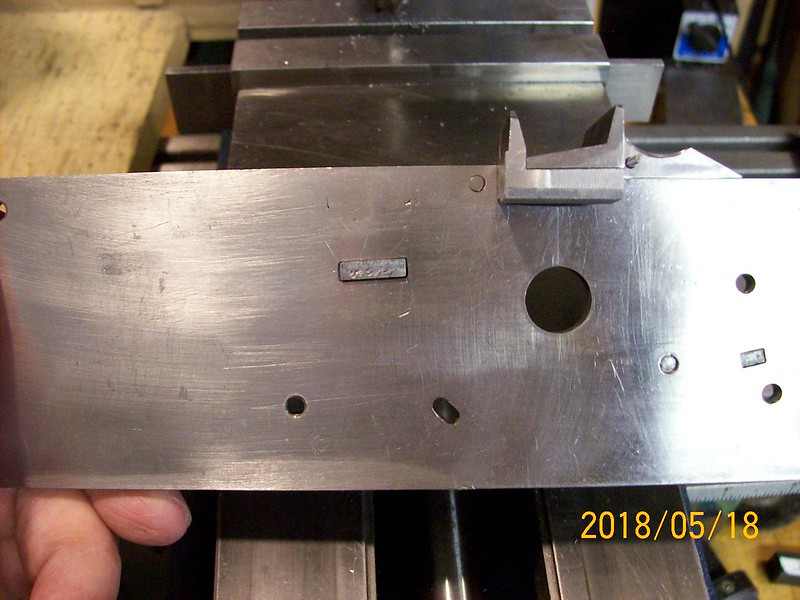

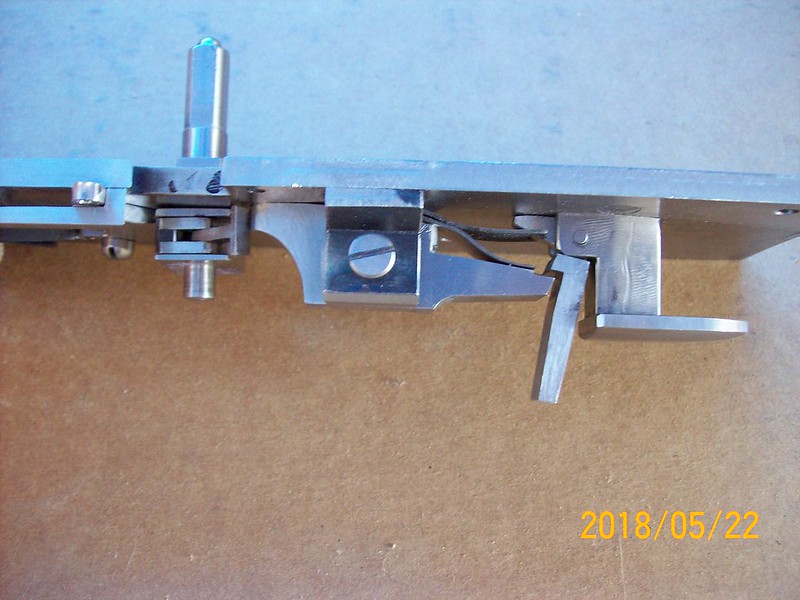

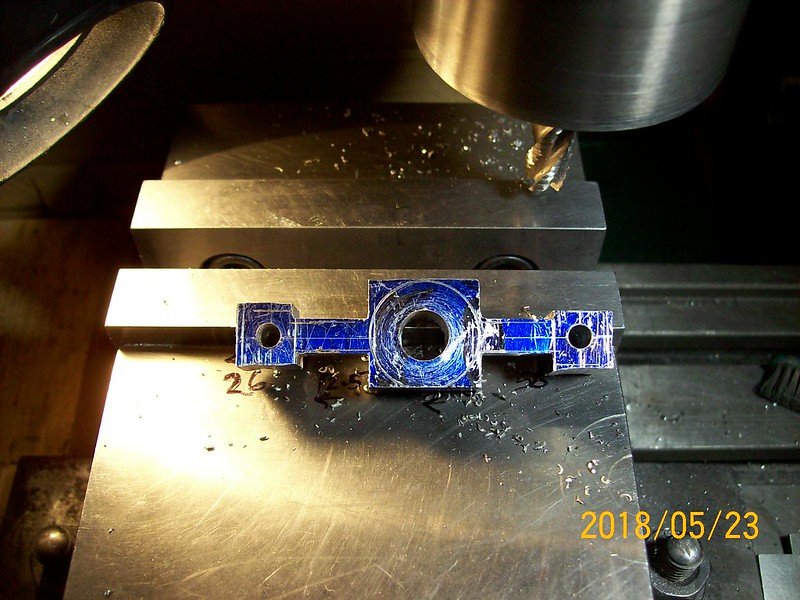

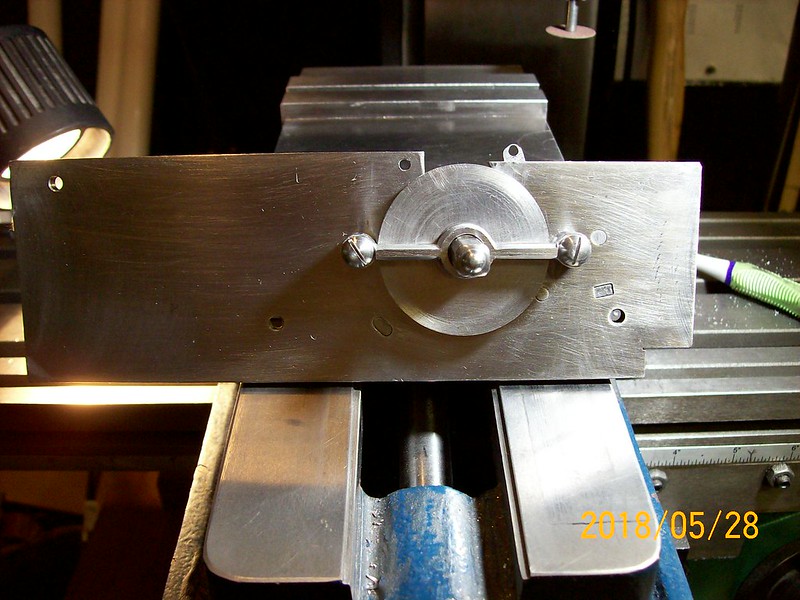

View showing mainspring support top rivet - used the 16 oz. machinist hammer this time. You can see that the mainspring bears against the support. I made the part asymmetric.

100_0594

100_0594

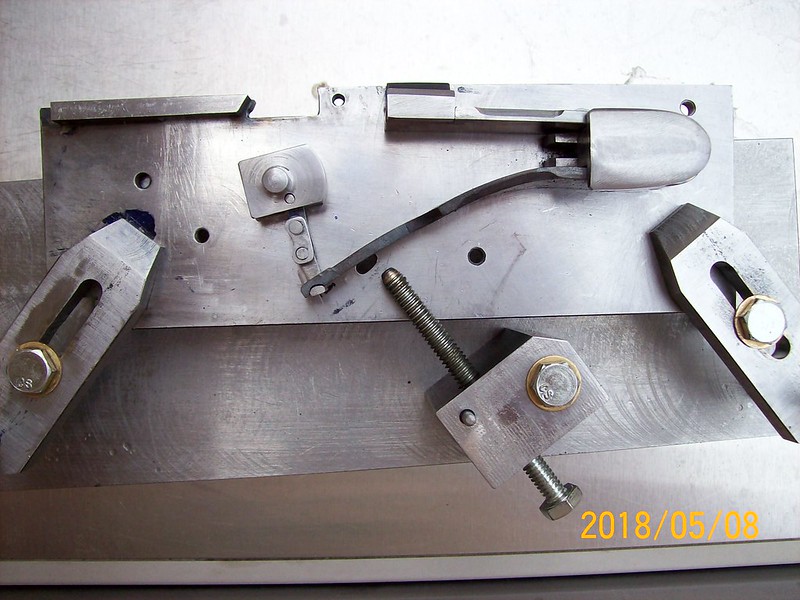

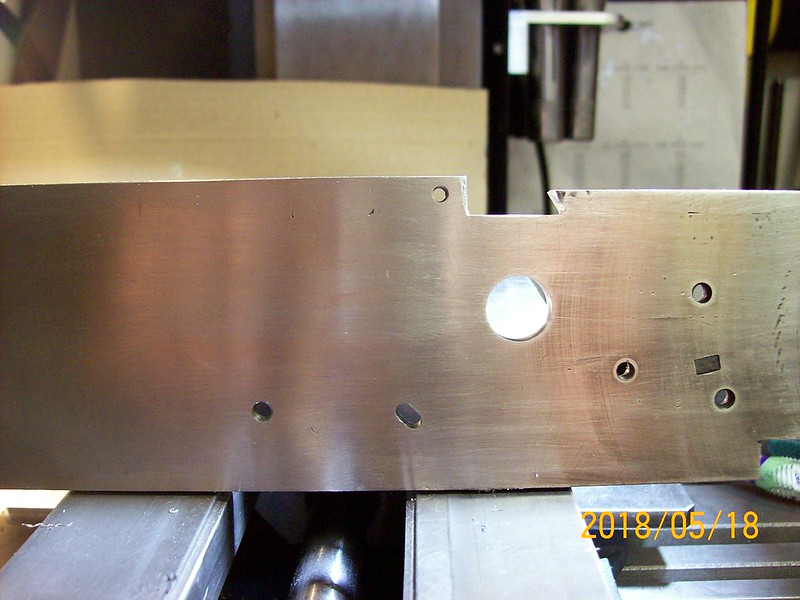

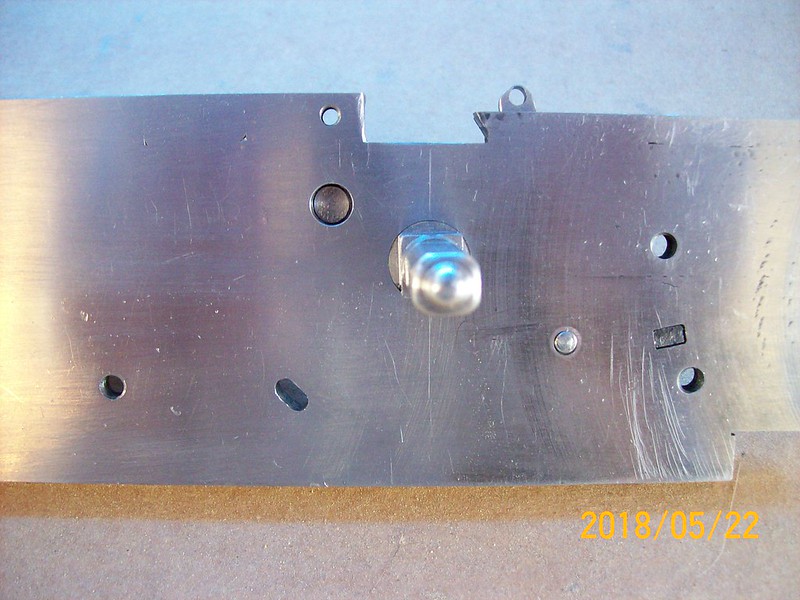

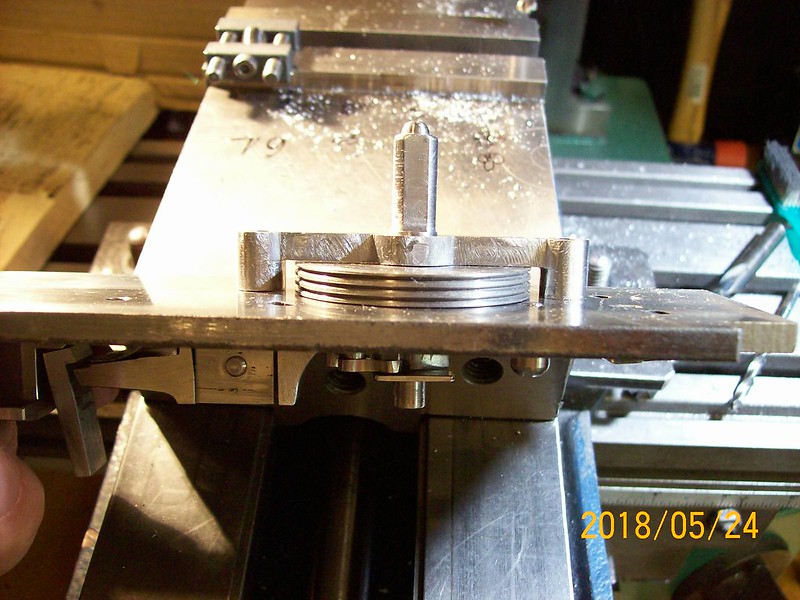

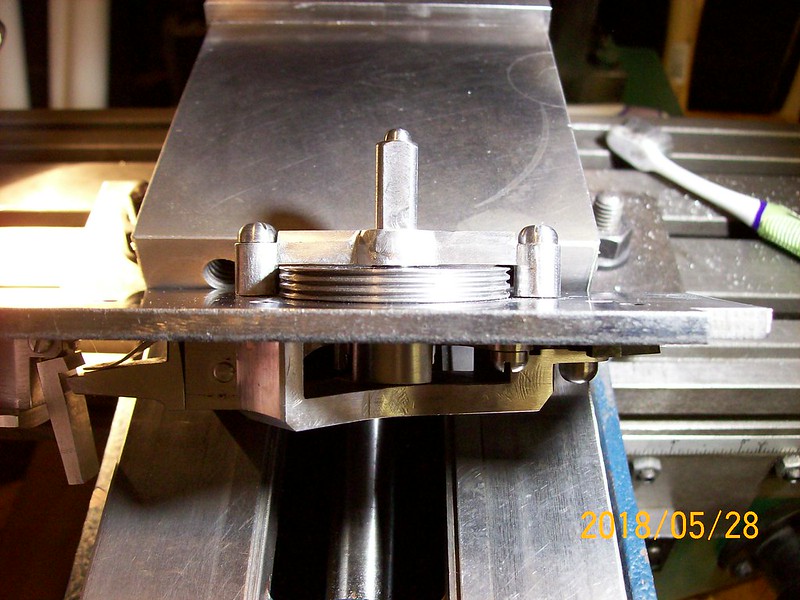

Support top smoothed out.

100_0596

100_0596

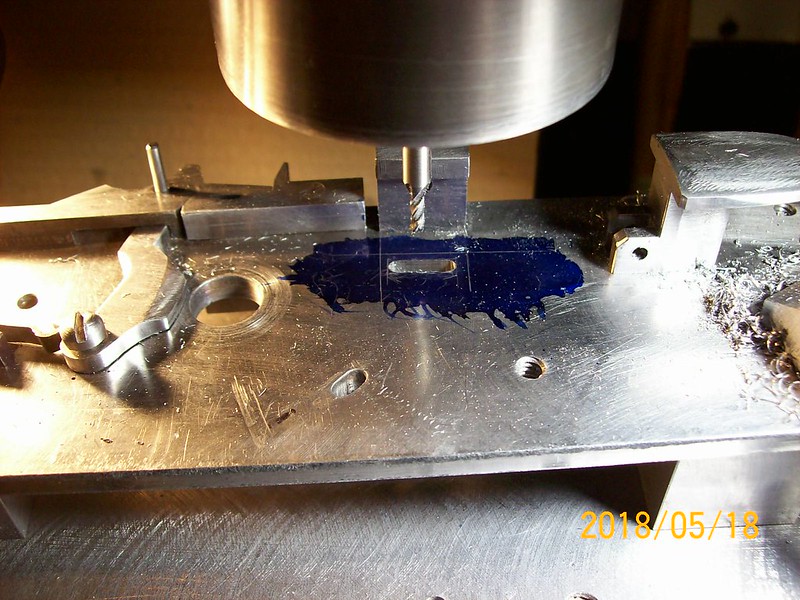

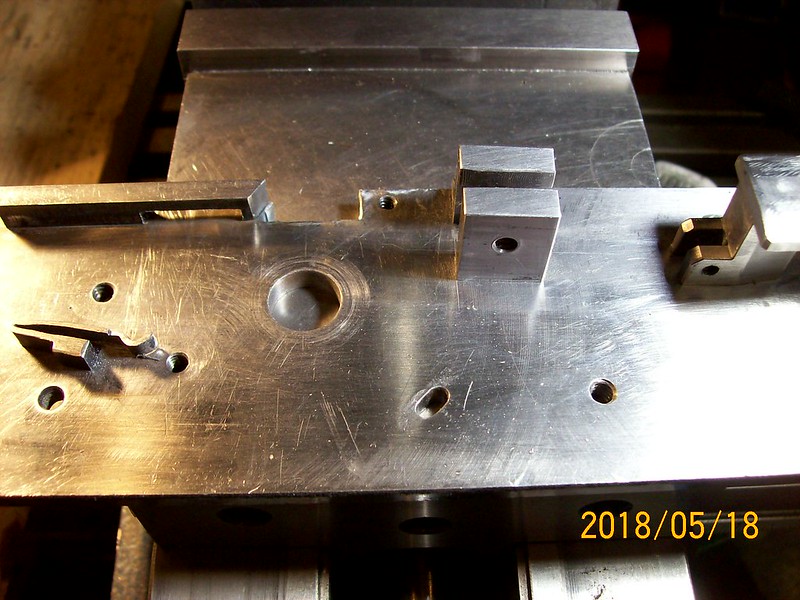

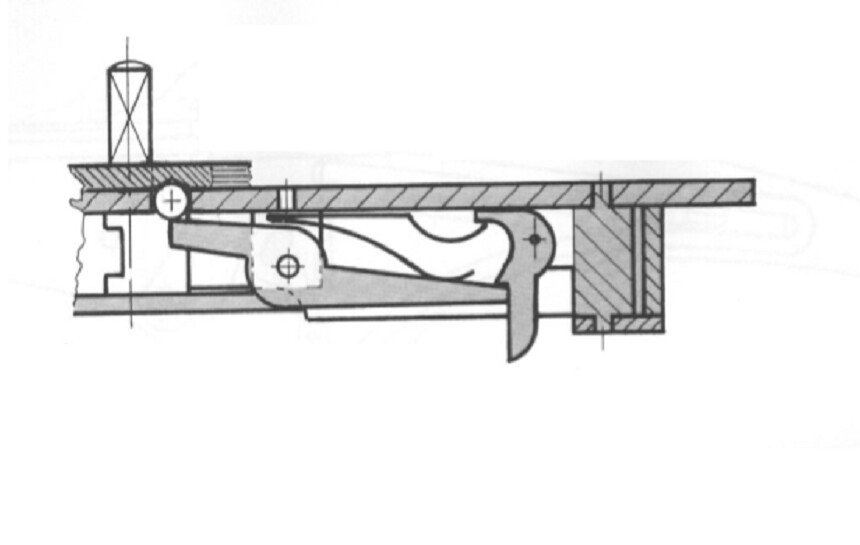

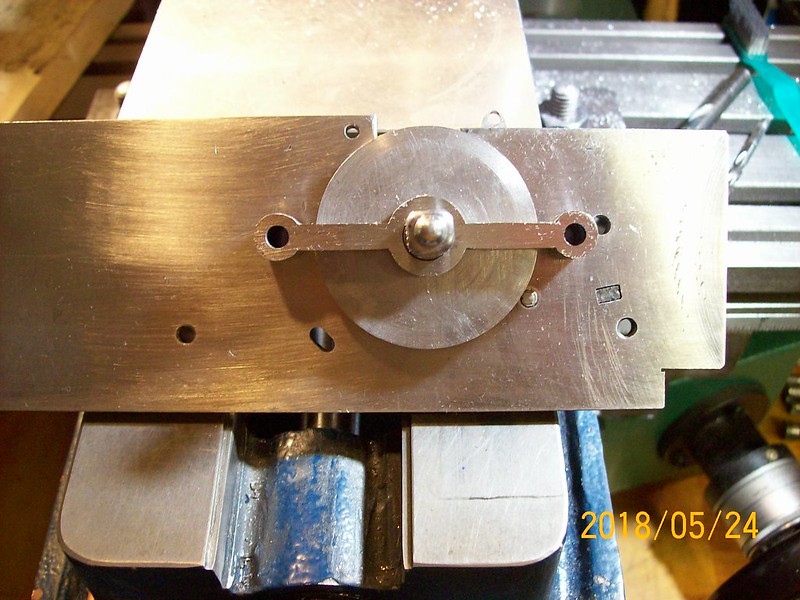

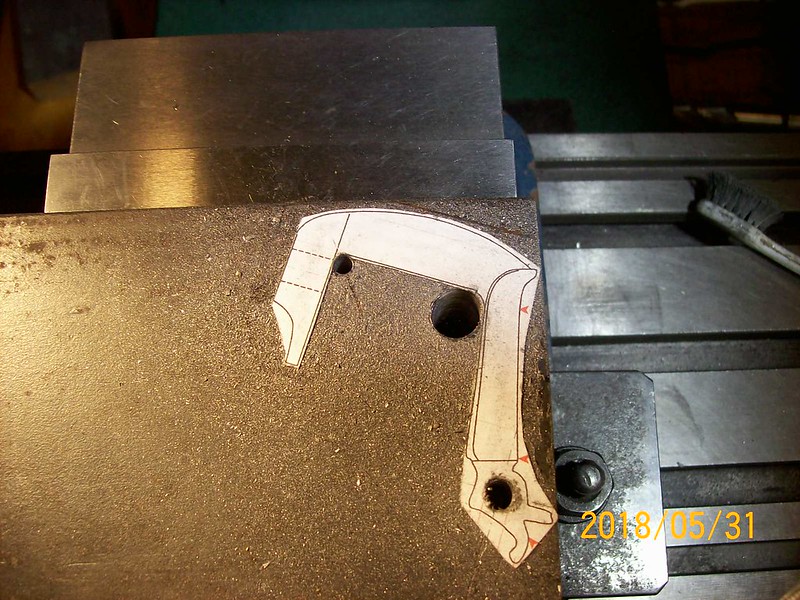

later, Mike (click on the photos & they'll enlarge at flickr)

100_0592

100_0592 View showing mainspring support top rivet - used the 16 oz. machinist hammer this time. You can see that the mainspring bears against the support. I made the part asymmetric.

100_0594

100_0594Support top smoothed out.

100_0596

100_0596 later, Mike (click on the photos & they'll enlarge at flickr)