This grows out of the discussion of Indian made ML muskets.

It has never been possible to "proof" a barrel made of inferior or improper materials and "prove" its safe. It may stand proof then fail with some subsequent shot with a service load.

This was true in the 18th Century and its still true today.

The act of over pressuring an improperly made/improper alloy barrel when "proving" can hasten a later failure.

In The Gun by W. Greener (not W.W.) in 1835 he points put the barrels sometime fail with a service charge after being proved. He thought it was a sign that the mode of prove was lacking.

However, considering the state of metallurgy at the time it is surprising to me that more did not fail. They failed due to an unsuitable alloy or other flaw in their making.

A GOOD iron barrel will easily contain BP pressures, especially with flint ignition. The Muskets used in our Civil War were ALL iron and very few if any failed after proof.

Steel is stronger.

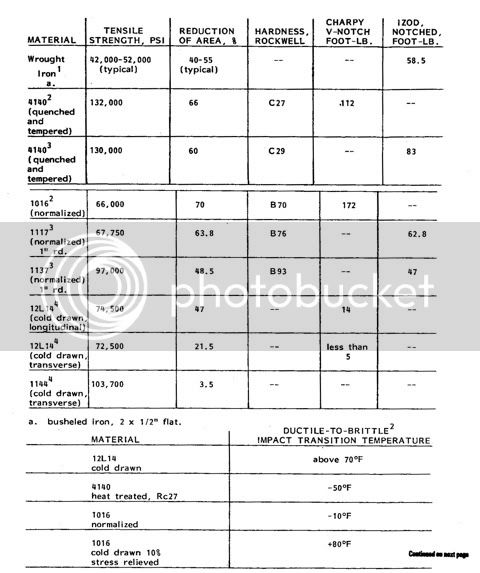

HOWEVER, the alloy is critical. Choose the wrong alloy and a barrel that passes proof can still fail due to the alloy or the manufacturing process being incorrect for the usage.

Proving only finds gross flaws. It cannot protect against shoddy workmanship, improper alloys or improper processes in steel making or in making the final product.

Back circa 1969-71 a friend showed me a 13/16" 45 cal Douglas that burst with a service load on the first shot. It split up the top flat for about a foot from the breech forward.

I going through some old magazines I found in the basement a couple of days ago I found a piece in a 1972 Muzzle Blasts with a 13/16 x 45 douglas that failed in the same manner. 70 gr of FFG in this case and Roy Keeler who wrote the article assured the reader it was properly loaded. Roy stated that he had gotten lax after proving 100s of barrels over the years and decided it was not necessary and he soon had this failure due to flaws in the steel.

Some steels and some PROCESSES for making tubing WILL NOT tolerate internal pressure well or shock loading (fast pressure rise). Gun barrels are subject to both. This means that alloys and manufacturing methods must be proper for the job.

Some individuals will try to make a case for "seamless" or welded tubing. They like to use the argument that all the old barrels were welded tubes. They fail to take into consideration that.

1. Lots of barrels failed killing and maiming people "back in the day".

2. That iron welds far easier than steel does.

3. Through trial and error over CENTURIES barrel forgers found what worked best. But they were hampered by metallurgy and in many cases greed so some barrels, either knowingly or otherwise were seriously flawed when they left the forge.

There has ALWAYS been a problem with cheap poorly made barrels. Firearms build for the North American and Africa native trade generally had VERY poor barrels. Many had forged proof marks (according the W. Greener) and were never proved. Some barrels recovered from NA sites and subjected to microscopic analyses sjow the barrels coming to NA natives were riddled with inclusions and "greys" that would have almost surely caused immediate failure with modern powders.

Powder:

Powder from the 18th century, especially the stuff exported, was much weaker than that in use today. Thus an 18th century trade gun/musket/rifle barrel that was "safe" in the day might bulge or burst if proved or simply fired with modern powder with its faster burn rates.

MY OPINION...

There are LOTS of ML barrels being made of materials that a metallurgist would say were unsuitable. Makers here and apparently abroad as well are doing this.

There are photos of a burst Indian made musket. It was burst with a BLANK charge reportedly with NO WADDING.

It is a VERY similar split to the Douglas barrels above. There is one exception. Parts of the split are cleaner, as if the welding or drawing process did not "stick" the tube together.

Though I have not personally seen the barrel from the photos I think:

1. The barrel was seriously flawed and was never proved.

2. The Indian made musket had a barrel made in a manner unacceptable to modern barrel making standards.

It was meant to be a wall hanger or a movie prop in all likelyhood and the maker almost certainly did not drill a vent so it could be fired. This was almost surely done at some time AFTER the gun was finished and according to at least one firm selling these things drilling a vent voids the warranty.

In my opinion people who shoot these things or witness them being fired is foolish.

From a Web Site selling such things:

*****************

"Our Guarantee

If upon receiving your musket you are not completely happy with your purchase, you may return it for a refund. All we ask is you cover the shipping costs.

Non-Firing State

We sell historically accurate muskets as a non-firing state. This allows us to comply with local, state, national and international firearms regulations. A certified gunsmith may alter this musket to a firing state by drilling the vent hole and test firing it. We are not legally responsible for any alteration from its present non-firing state."

*********************

One should carefully read the last sentence.

Dan

It has never been possible to "proof" a barrel made of inferior or improper materials and "prove" its safe. It may stand proof then fail with some subsequent shot with a service load.

This was true in the 18th Century and its still true today.

The act of over pressuring an improperly made/improper alloy barrel when "proving" can hasten a later failure.

In The Gun by W. Greener (not W.W.) in 1835 he points put the barrels sometime fail with a service charge after being proved. He thought it was a sign that the mode of prove was lacking.

However, considering the state of metallurgy at the time it is surprising to me that more did not fail. They failed due to an unsuitable alloy or other flaw in their making.

A GOOD iron barrel will easily contain BP pressures, especially with flint ignition. The Muskets used in our Civil War were ALL iron and very few if any failed after proof.

Steel is stronger.

HOWEVER, the alloy is critical. Choose the wrong alloy and a barrel that passes proof can still fail due to the alloy or the manufacturing process being incorrect for the usage.

Proving only finds gross flaws. It cannot protect against shoddy workmanship, improper alloys or improper processes in steel making or in making the final product.

Back circa 1969-71 a friend showed me a 13/16" 45 cal Douglas that burst with a service load on the first shot. It split up the top flat for about a foot from the breech forward.

I going through some old magazines I found in the basement a couple of days ago I found a piece in a 1972 Muzzle Blasts with a 13/16 x 45 douglas that failed in the same manner. 70 gr of FFG in this case and Roy Keeler who wrote the article assured the reader it was properly loaded. Roy stated that he had gotten lax after proving 100s of barrels over the years and decided it was not necessary and he soon had this failure due to flaws in the steel.

Some steels and some PROCESSES for making tubing WILL NOT tolerate internal pressure well or shock loading (fast pressure rise). Gun barrels are subject to both. This means that alloys and manufacturing methods must be proper for the job.

Some individuals will try to make a case for "seamless" or welded tubing. They like to use the argument that all the old barrels were welded tubes. They fail to take into consideration that.

1. Lots of barrels failed killing and maiming people "back in the day".

2. That iron welds far easier than steel does.

3. Through trial and error over CENTURIES barrel forgers found what worked best. But they were hampered by metallurgy and in many cases greed so some barrels, either knowingly or otherwise were seriously flawed when they left the forge.

There has ALWAYS been a problem with cheap poorly made barrels. Firearms build for the North American and Africa native trade generally had VERY poor barrels. Many had forged proof marks (according the W. Greener) and were never proved. Some barrels recovered from NA sites and subjected to microscopic analyses sjow the barrels coming to NA natives were riddled with inclusions and "greys" that would have almost surely caused immediate failure with modern powders.

Powder:

Powder from the 18th century, especially the stuff exported, was much weaker than that in use today. Thus an 18th century trade gun/musket/rifle barrel that was "safe" in the day might bulge or burst if proved or simply fired with modern powder with its faster burn rates.

MY OPINION...

There are LOTS of ML barrels being made of materials that a metallurgist would say were unsuitable. Makers here and apparently abroad as well are doing this.

There are photos of a burst Indian made musket. It was burst with a BLANK charge reportedly with NO WADDING.

It is a VERY similar split to the Douglas barrels above. There is one exception. Parts of the split are cleaner, as if the welding or drawing process did not "stick" the tube together.

Though I have not personally seen the barrel from the photos I think:

1. The barrel was seriously flawed and was never proved.

2. The Indian made musket had a barrel made in a manner unacceptable to modern barrel making standards.

It was meant to be a wall hanger or a movie prop in all likelyhood and the maker almost certainly did not drill a vent so it could be fired. This was almost surely done at some time AFTER the gun was finished and according to at least one firm selling these things drilling a vent voids the warranty.

In my opinion people who shoot these things or witness them being fired is foolish.

From a Web Site selling such things:

*****************

"Our Guarantee

If upon receiving your musket you are not completely happy with your purchase, you may return it for a refund. All we ask is you cover the shipping costs.

Non-Firing State

We sell historically accurate muskets as a non-firing state. This allows us to comply with local, state, national and international firearms regulations. A certified gunsmith may alter this musket to a firing state by drilling the vent hole and test firing it. We are not legally responsible for any alteration from its present non-firing state."

*********************

One should carefully read the last sentence.

Dan