I'm playing around with parts I have laying around (I enjoy doing things like this) I am converting a traditions percussion deer hunter into a flintlock.

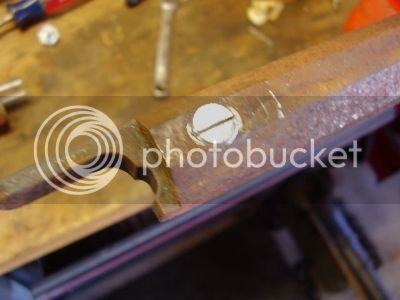

I have read numerous posts & done Internet searches on this & I understand what I need to do. I will not remove the Nipple barrel, I will cut it off & surface grind it flush to the barrel (yes I work at a cnc machine shop the last 23 years) I will drill & tap for a 1/4 x 28 vent liner.

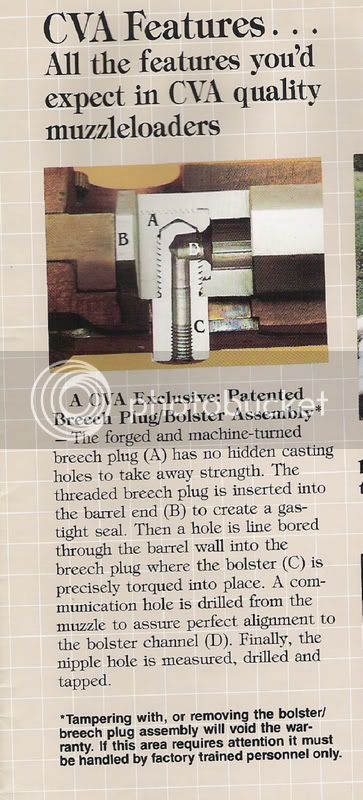

I will let you all know I understand how traditions runs the nipple barrel threads thru the breach plug & then run an angular hole to the barrel bore. I realize this might make a tempermentle gun to ignite (I'm willing to play & learn)

Now for my concern........... I realize a normal vent liner goes thru the barrel & should be ground flush inside the bore so it does not protude. A good instalation would not have any threads (male or female) being exposed to ignition of the powder. What I am trying to do will have the female threads exposed behind the vent liner, is that a concern ?

I did purchase a blind hole tap with only 1 turn of thread tapered verses a normal tap having 5 or more tapered threads before a good full thread. I will use a "normal tapered tap" to start but I will finish with a blind hole tap to minimize threads in the vent channel.

Is this correct thinking ? Or am I worrying about things that don't matter ?

Thanks,

Dan

I have read numerous posts & done Internet searches on this & I understand what I need to do. I will not remove the Nipple barrel, I will cut it off & surface grind it flush to the barrel (yes I work at a cnc machine shop the last 23 years) I will drill & tap for a 1/4 x 28 vent liner.

I will let you all know I understand how traditions runs the nipple barrel threads thru the breach plug & then run an angular hole to the barrel bore. I realize this might make a tempermentle gun to ignite (I'm willing to play & learn)

Now for my concern........... I realize a normal vent liner goes thru the barrel & should be ground flush inside the bore so it does not protude. A good instalation would not have any threads (male or female) being exposed to ignition of the powder. What I am trying to do will have the female threads exposed behind the vent liner, is that a concern ?

I did purchase a blind hole tap with only 1 turn of thread tapered verses a normal tap having 5 or more tapered threads before a good full thread. I will use a "normal tapered tap" to start but I will finish with a blind hole tap to minimize threads in the vent channel.

Is this correct thinking ? Or am I worrying about things that don't matter ?

Thanks,

Dan