-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enfield Paper Cartridge bullet

- Thread starter RAEDWALD

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

KanawhaRanger said:Actually the American cartridge is made of 3 pieces, although in a different way than the Enfield. There's a thread on here that shows the construction, but Momma's calling me for supper so I don't have time to find the link right now.

The 1861 Ordnance manual only talks of two pieces,the cartridge case and the powder cylinder.

I'm thinkin' if I added the bullet to the cartridge case and the powder I'd have 3 pieces.

OK.

You guys have gotten me off my butt to go digging in my closet.

In Volume 64- No. 2 of the National Muzzle Loading Rifle Associations magazine Muzzle Blasts, Oct., 2002 on page 65 is an article written by Stuart Cruickshank entitled,

"The Enfield Rifle Musket and its Complex Paper Cartridge".

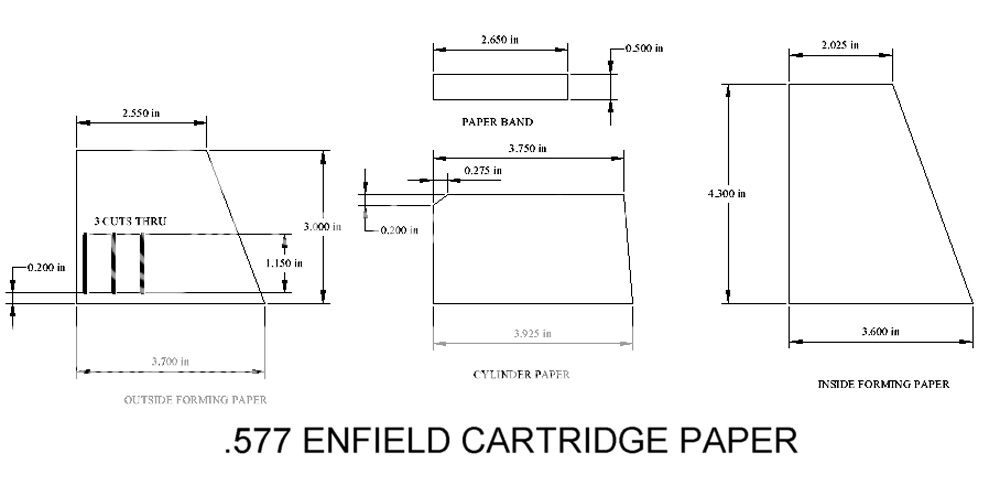

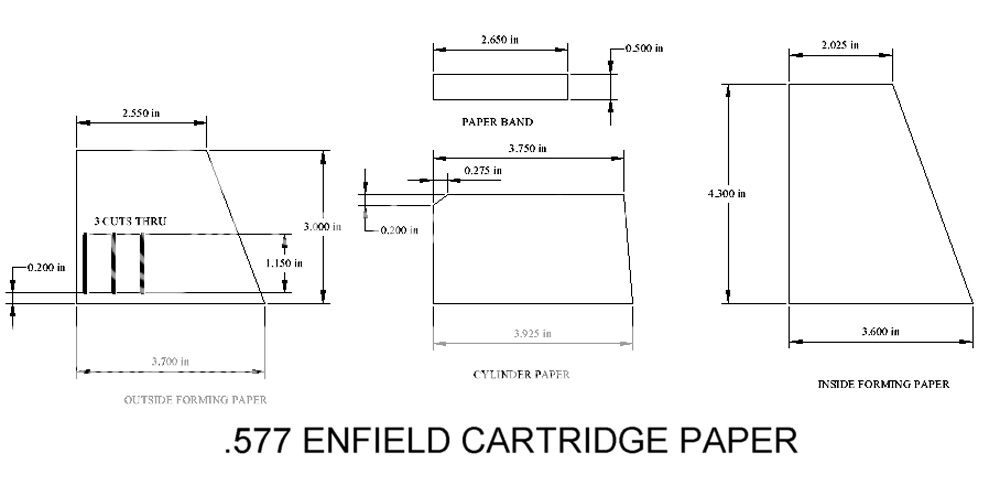

The 6 page article shows photos of making the cartridge, the drawings and dimensions for the sizes of the 4 pieces of paper needed and a great deal of written information about the history and the making of a Enfield cartridge.

The 4 pieces of paper shown are the Cylinder Paper, the Inside Formed Paper, the Outside Formed Paper and the Paper Band.

I remember when reading this article back in 2002 my first thought was, "Boy! That's one hell of a lot of work for something to cram down a muzzle and then blow it all to hell."

With that in mind, I never thought about making these again until recently when this topic came up.

No, I didn't change my mind. I just recalled the article and thought I'd tell you where it is. :grin:

You guys have gotten me off my butt to go digging in my closet.

In Volume 64- No. 2 of the National Muzzle Loading Rifle Associations magazine Muzzle Blasts, Oct., 2002 on page 65 is an article written by Stuart Cruickshank entitled,

"The Enfield Rifle Musket and its Complex Paper Cartridge".

The 6 page article shows photos of making the cartridge, the drawings and dimensions for the sizes of the 4 pieces of paper needed and a great deal of written information about the history and the making of a Enfield cartridge.

The 4 pieces of paper shown are the Cylinder Paper, the Inside Formed Paper, the Outside Formed Paper and the Paper Band.

I remember when reading this article back in 2002 my first thought was, "Boy! That's one hell of a lot of work for something to cram down a muzzle and then blow it all to hell."

With that in mind, I never thought about making these again until recently when this topic came up.

No, I didn't change my mind. I just recalled the article and thought I'd tell you where it is. :grin:

Last edited by a moderator:

At the moment I can't open that link but with my luck it shows what I just spent time drawing for you folks.

If it works, here is the dimensions of the paper you will need to cut.

The article I mentioned showed the drawing for the cartridges that were used by Enfield in 1863

If it works, here is the dimensions of the paper you will need to cut.

The article I mentioned showed the drawing for the cartridges that were used by Enfield in 1863

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

My 1862 Manual omits the third piece as well, probably because of wartime production changes. Omitting the cylinder case removed a step or two from the process. This case was not wholly necessary, but aided in keeping the powder from contacting the grease on the bullet. It also helped in breaking the cartridge in loading. It was made of rocket paper. Below is a diagram showing the shapes of the papers used and the dotted line shows the position of the cylinder case on the wrapper when wound around the forming stick.

[/img]

[/img]

Zonie, quite a difference between the two nations here, huh?

Zonie, quite a difference between the two nations here, huh?

RAEDWALD

40 Cal.

All fascinating stuff, but I think that I can take it that the answer to my question is that there is no suitable mould. So my options are to pay more than I can afford, lap a 0.54" mould or squeeze a 0.58" bullet.

How might the base insert cope in a 0.54" mould if it were lapped out 0.55" (if indeed it could be?)

Also, from a discussion on a French site, it was suggested that the original role of the base plug was to encourage expansion in lead of variable hardness. French period thinking was that troops would expect to use 'found' lead to cast there own in the field and this could be of any hardness, certainly up to modern wheel weight standard. I know the UK and USA references stress soft pure lead but does anyone have anything to offer on the base plug/hardness hypothesis?

(If a moderator thinks this latter should be a different thread I am happy to oblige.)

How might the base insert cope in a 0.54" mould if it were lapped out 0.55" (if indeed it could be?)

Also, from a discussion on a French site, it was suggested that the original role of the base plug was to encourage expansion in lead of variable hardness. French period thinking was that troops would expect to use 'found' lead to cast there own in the field and this could be of any hardness, certainly up to modern wheel weight standard. I know the UK and USA references stress soft pure lead but does anyone have anything to offer on the base plug/hardness hypothesis?

(If a moderator thinks this latter should be a different thread I am happy to oblige.)

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

It shouldn't affect the base insert, but the skirt of the bullet will be thicker because you're adding to the outside diameter.

I've lost count of the number of posts on different forums of folks wanting the Enfield Pritchett pattern bullet mold.Lee will do custom order bullet molds I think but it requires a certain number of molds to be ordered.Is there enough interest out there for that?

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

I had a few swaged Pritchetts that I shot from a EuroArms Enfield I used to have. Never had much luck with them. Actually I still have a handful. Oughta see what can be done about making a mold using them as a pattern.

RAEDWALD

40 Cal.

Thank you, I may well go down this road unless the rifle turns out to be of generous bore.

Having scouted through the net I have come to the conclusion that there is a definite market for a Pritchett to a market that wants to make authentic enfield paper cartridges and might sell best specifically directed to that market, perhaps with instructions/templates to make up the cartridges.

Looking at the shallow Pritchett base hollow one might almost be forgiven for wondering if it expands at all or if it is the paper acting as a sabot that does the job.

Having scouted through the net I have come to the conclusion that there is a definite market for a Pritchett to a market that wants to make authentic enfield paper cartridges and might sell best specifically directed to that market, perhaps with instructions/templates to make up the cartridges.

Looking at the shallow Pritchett base hollow one might almost be forgiven for wondering if it expands at all or if it is the paper acting as a sabot that does the job.

ResearchPress

45 Cal.

There's been a lot of discussion on the British Militaria forum about Pritchett bullet shooting, drawings are also available in the discussion for a mould that has been made.

My Research Press web site has information on making and loading the cartridges.

I'll send links in PM.

David

My Research Press web site has information on making and loading the cartridges.

I'll send links in PM.

David

KanawhaRanger said:I had a few swaged Pritchetts that I shot from a EuroArms Enfield I used to have. Never had much luck with them. Actually I still have a handful. Oughta see what can be done about making a mold using them as a pattern.

Did you shoot them naked or with the paper on them as designed?

I picked up one of the EuroArms London Armory models.Seems a lot of the problem on someone offering a Pritchett mold is the different bore diameters depending on whose Enfield you have,original,P-H.,Euroarms,etc.

Tumblernotch

69 Cal.

- Joined

- Feb 26, 2005

- Messages

- 3,370

- Reaction score

- 11

To be honest I shot them naked. That was many years ago before I knew that they were patched. I did grease them up, but I'd say there was too much windage. I kept 2 or 3 for my collection, didn't have more than half a dozen or so to start with.

My EuroArms LA shot .575 505 gr. Lee Minies quite well. It might have done fine with the Pritchetts but back then I didn't have any proper tools to measure bullets with. I know I wish that I had kept that Enfield.

My EuroArms LA shot .575 505 gr. Lee Minies quite well. It might have done fine with the Pritchetts but back then I didn't have any proper tools to measure bullets with. I know I wish that I had kept that Enfield.

Good to know about the .575 minie,got that size mold.Haven't shot it yet,picked it up about the time the weather started getting too bad to shoot and too cold to cast outdoors.Thought about removing the grease grooves from a mold but it still won't give the right size to make a shootable paper cartridge of the Enfield pattern using the paper as patching unless I could find an undersize mold.Need to do some looking at suitable paper types and thicknesses.

Hawes's book has a section on casting bullets in the field and describes a hand operated bullet sizer pretty much like the one Rapine used to sell to make the hand cast bullets the correct diameter.But that would have limits on how much you could reduce a bullet even using graduated sizing dies I imagine.

Hawes's book has a section on casting bullets in the field and describes a hand operated bullet sizer pretty much like the one Rapine used to sell to make the hand cast bullets the correct diameter.But that would have limits on how much you could reduce a bullet even using graduated sizing dies I imagine.

Similar threads

- Replies

- 4

- Views

- 463

- Replies

- 0

- Views

- 307

- Replies

- 13

- Views

- 909

- Replies

- 36

- Views

- 3K