- Joined

- Jun 4, 2014

- Messages

- 3,936

- Reaction score

- 4,710

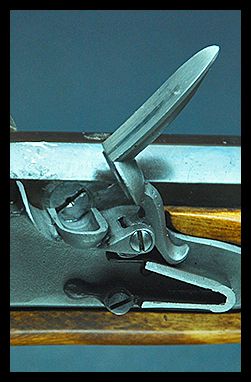

Recently purchased an older Dixie TN Mt. Rifle, in .50, that is a percussion. Also picked up an L&R replacement flint lock and a vent(5/16 x 24) with the idea of going to flint. When I got the vent from Dixie I also picked up an extra drum as the screw was buggered on the original.

The lock fit well with just a little shaving in the mortice, nice and tight and right up to the barrel, lined up nice.

My problem is with the vent. It will go in a turn or two, then stop, and it seems it would take considerable force to continue. The same is true of the new drum, while the old drum screws right in, no problem. The threads are very close on all, but the newer parts, and it may be just my imagination, seem just a little different. Even with a thread gauge its hard to see any difference, at least with my older eyes. I don't want to force the vent and screw up the threads. What do I have wrong here? Any Ideas?

The lock fit well with just a little shaving in the mortice, nice and tight and right up to the barrel, lined up nice.

My problem is with the vent. It will go in a turn or two, then stop, and it seems it would take considerable force to continue. The same is true of the new drum, while the old drum screws right in, no problem. The threads are very close on all, but the newer parts, and it may be just my imagination, seem just a little different. Even with a thread gauge its hard to see any difference, at least with my older eyes. I don't want to force the vent and screw up the threads. What do I have wrong here? Any Ideas?