Nitsudttesrod

32 Cal.

- Joined

- May 9, 2016

- Messages

- 26

- Reaction score

- 0

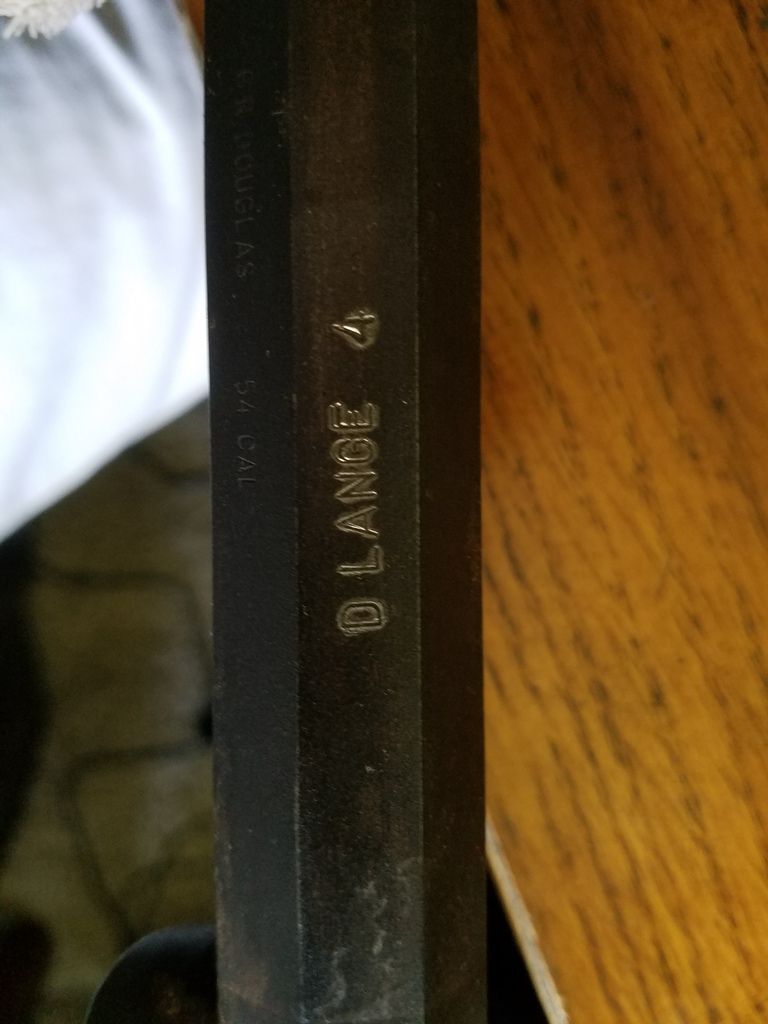

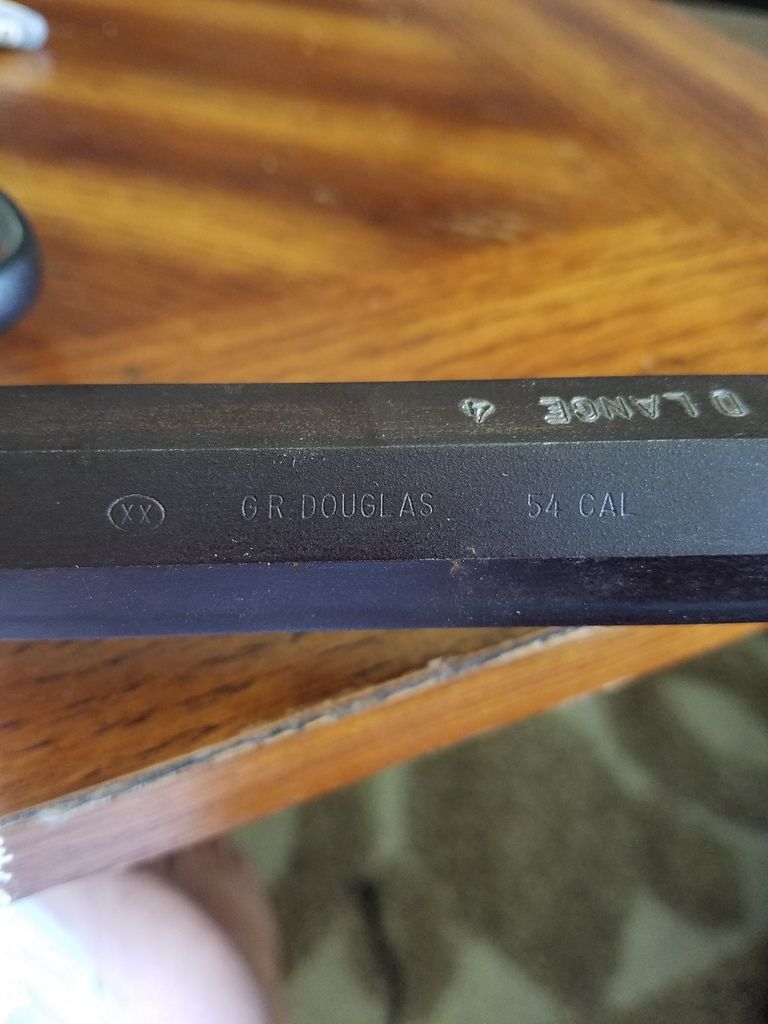

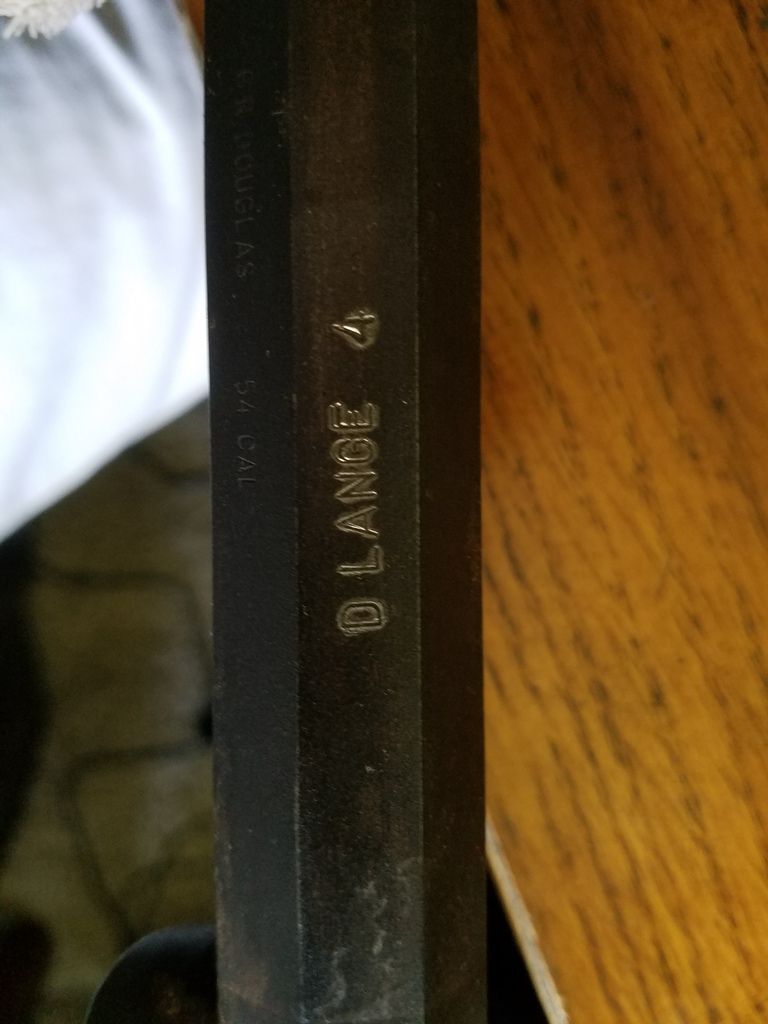

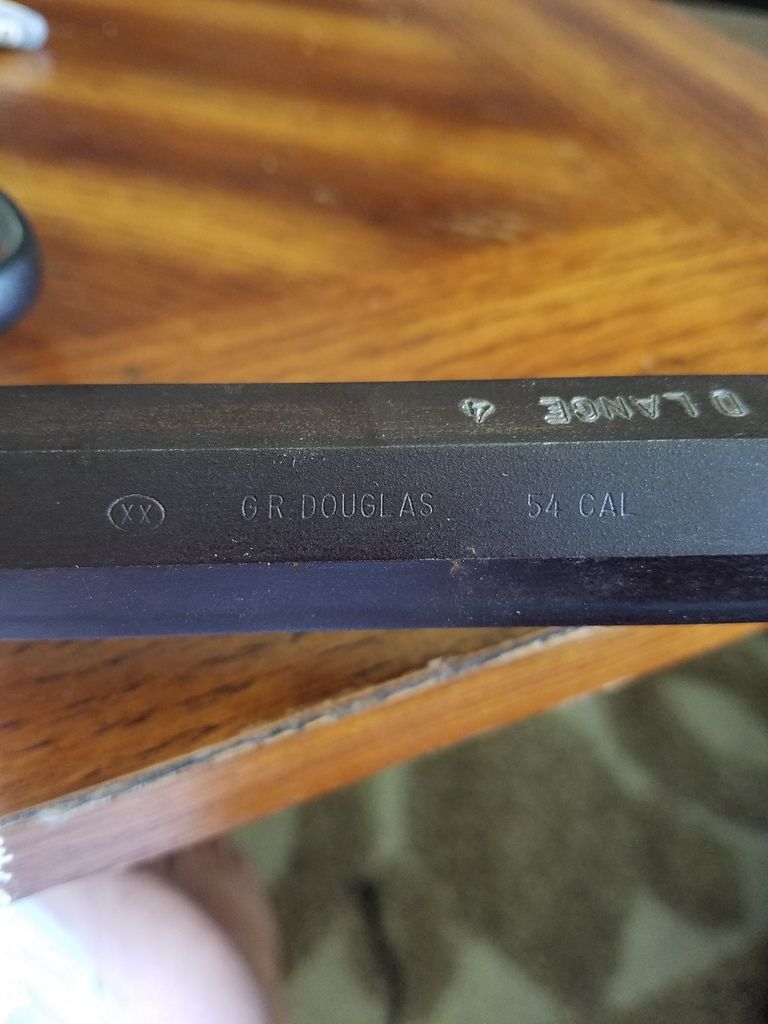

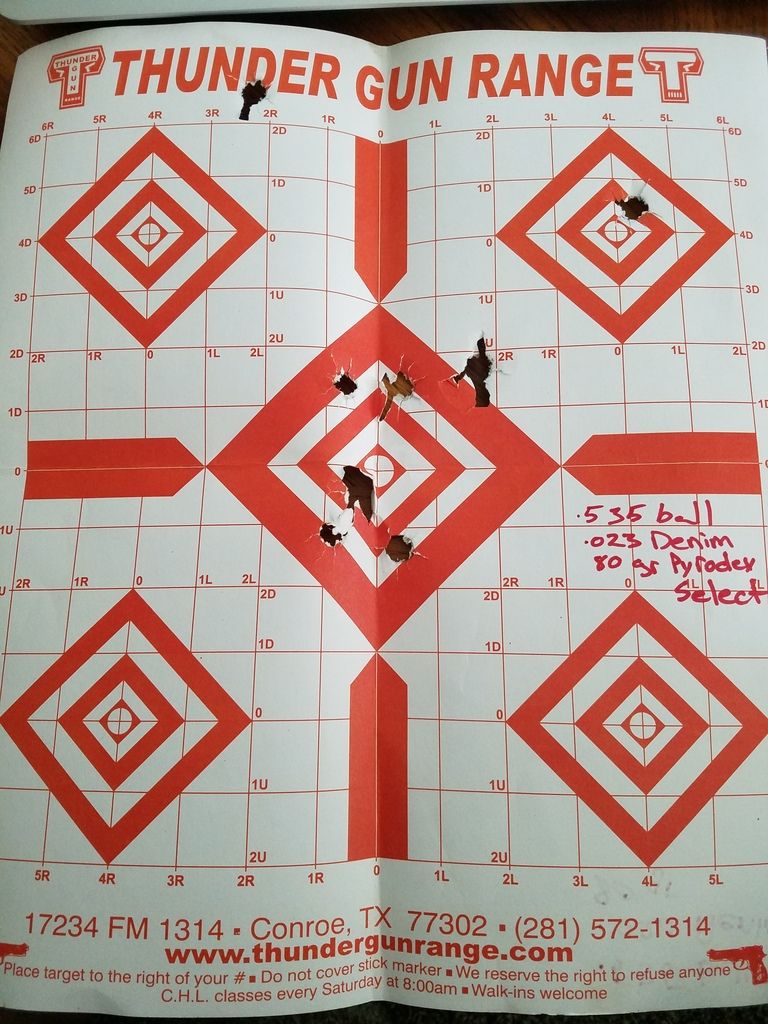

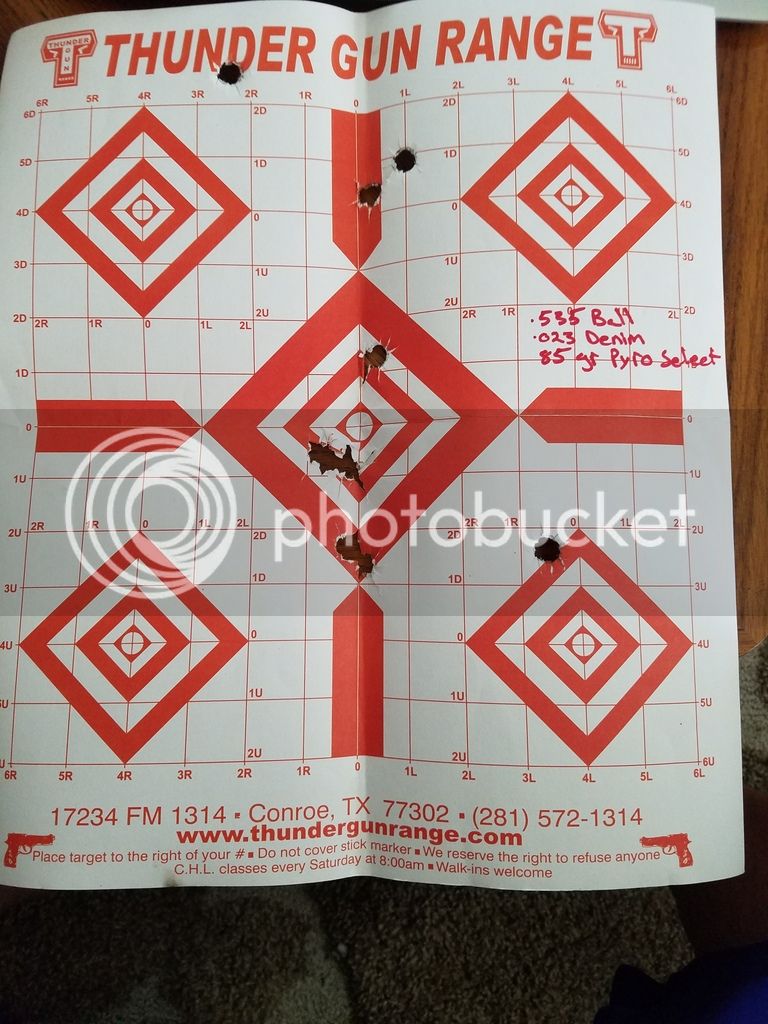

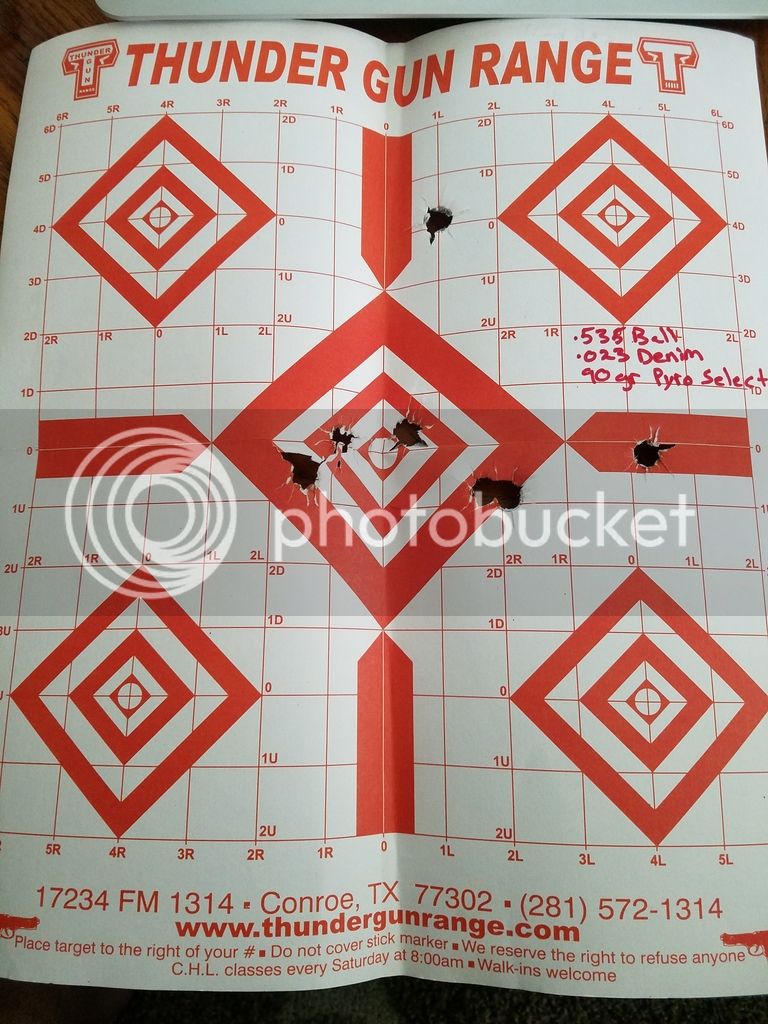

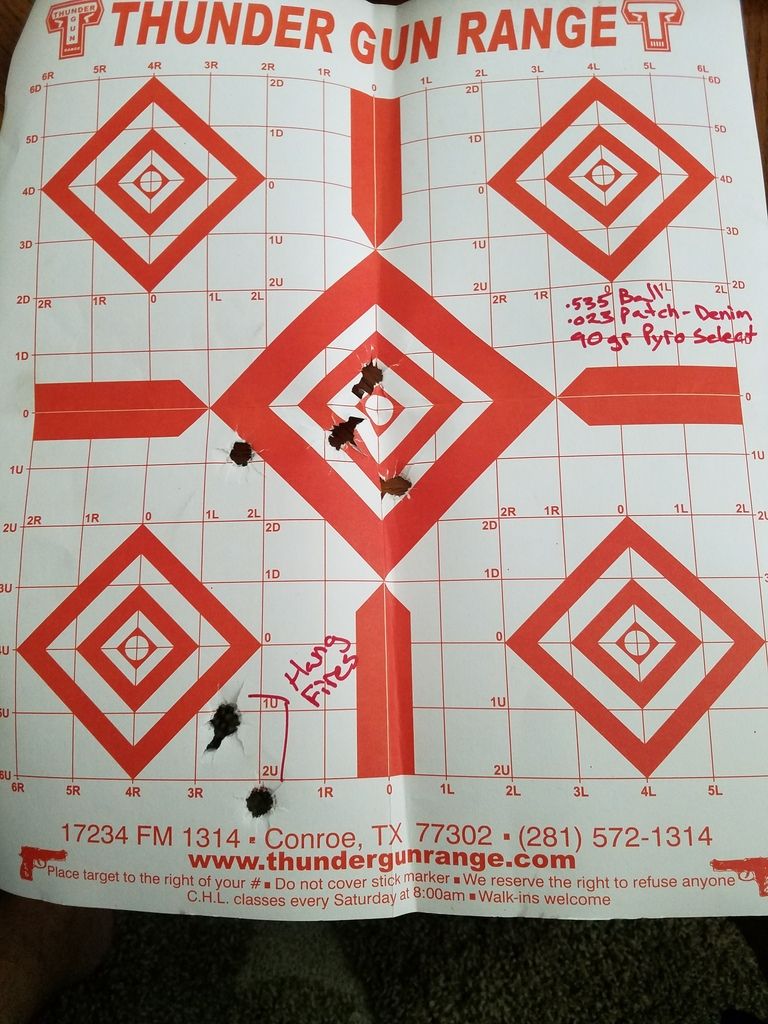

About a two months ago I acquired .54 caliber custom plains style rifle. So far I have assembled all supplies needed to get her smoking and have settled on a .535 round ball with .023" denim patches lubed with Dutch's dry patch system on top of 90gr of pyrodex select. I would love to try the real black powder stuff but here in Houston TX its pretty much impossible to find and at this time I don't want to lay out the cash to buy in bulk from the online retailers. I'm still in the process of developing the load but I'm consistently shooting about a 3" group right now after two sessions at the range at about 3 hours per session. And yes, I wipe between each shot with a dampened .011" patch. After the second range session I removed the barrel and lock to clean/ inspect for any rusting and found that the barrel is a 1:66" twist GR Douglas XX and the lock is a "Cherry Corners" lock. Everything looked ok but I have ordered a main spring vise so I can disassemble the lock to give it a thorough cleaning/lube. Are these barrels quality barrels and does anyone know anything about Cherry Corners locks? Here's some pics of my rifle.