I thought I saw a thread on here at one time about cutting round patches out off pillow ticking. there were a couple methouds. I would appreciate any feed back. thanks

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cutting round patches

- Thread starter uno676

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Sometimes square patches don't fit in my round tin that I converted into a patchbox. That's really the only difference that I have found between round and square. It's been my experience that they perform the same ballistics wise.

Check out Blackwoods . They have wad punches that will work quite well.

http://www.blackwoods.com.au/search/wad-punches/307219683?c=Product&page=2

http://www.blackwoods.com.au/search/wad-punches/307219683?c=Product&page=2

Last edited by a moderator:

don hepler

58 Cal.

- Joined

- Nov 19, 2010

- Messages

- 2,260

- Reaction score

- 10

I find a lid, or something the right diameter, and use a fine tip felt pen, to trace a circle. I use a tiny set of razor sharp sissers to cut out the circles. I can cut a whole pile in 20 minutes or so. That's just the way I role, your milage might vary.

Patocazador

54 Cal.

Ohio Ramrod on this forum will make you one to your specs. PM him.

Last edited by a moderator:

If they just absolutely, positively gotta be round, get one of the rotary cutters and go silly making round ones. When the blades start getting dull as they eventually will, they 'll cut pretty round leather patches just fine! :wink: :thumbsup:

Leather working arch punches, or wad cutters work the best. Use a piece of end grain wood under the cloth with a couple of pieces of card stock between the cloth, and wood. You should be able to cut through 15 to 20 layers at a time. Do not hit the punch with a steel hammer, use heavy wood, plastic, copper, or brass. New, or old punch, polish the inside until it shines. this will make cutting much easier.

Woody

Woody

yeah that was the thread I was thinking of Zonie. thanks

matt denison

54 Cal.

- Joined

- Aug 15, 2004

- Messages

- 1,786

- Reaction score

- 12

I have made hundreds of patches by cutting into squares then cutting again into circles - all with scissors. Then I got wise. I now call The Gun Works and ask Suzi to send me 1,000 precut patches in XX (whatever) size, and give her my credit card number. Takes about 45 seconds. :grin:

your probably the smart one. :haha:

Billnpatti

Cannon

- Joined

- Aug 11, 2008

- Messages

- 7,340

- Reaction score

- 40

I use an arch punch to cut mine. You can probably find a reasonably priced correct size arch punch at some place like Harbor Freight.

Buy one that is 3 times the diameter of the ball. Too much smaller and it may not wrap all the way around the ball. Too large and it can grab the tip of your short starter or the jag on your ramrod and be a booger to get loose.

But, you don't really need a round patch. Much experience has shown that square patches work just as well as round patches and are a whole lot easier to cut. If you have a .50 caliber rifle, cut a strip of patching material 1 1/2 inches wide and as long as the piece of cloth. If you want square patches, just cut the strip up into squares. You can also just leave it in a strip and cut your patches at the muzzle. All of the methods work just fine and it is your choice.

Buy one that is 3 times the diameter of the ball. Too much smaller and it may not wrap all the way around the ball. Too large and it can grab the tip of your short starter or the jag on your ramrod and be a booger to get loose.

But, you don't really need a round patch. Much experience has shown that square patches work just as well as round patches and are a whole lot easier to cut. If you have a .50 caliber rifle, cut a strip of patching material 1 1/2 inches wide and as long as the piece of cloth. If you want square patches, just cut the strip up into squares. You can also just leave it in a strip and cut your patches at the muzzle. All of the methods work just fine and it is your choice.

I never believed square worked well but I have tested and there is no difference. ALOT easier than sitting there watching NCIS with the wifes sewing scissors!

I shall now use the strip method and get some strips and lube em and roll em up and keep in a pill bottle and cut at the muzzle. then u get circles anyway and can recover about 1/2 and use again!

Life is good! Its better with Crown Royale.

I shall now use the strip method and get some strips and lube em and roll em up and keep in a pill bottle and cut at the muzzle. then u get circles anyway and can recover about 1/2 and use again!

Life is good! Its better with Crown Royale.

- Joined

- Dec 25, 2011

- Messages

- 8,796

- Reaction score

- 3,785

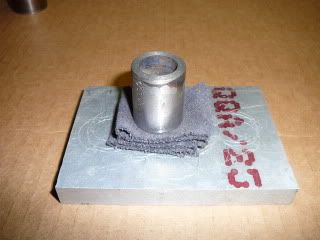

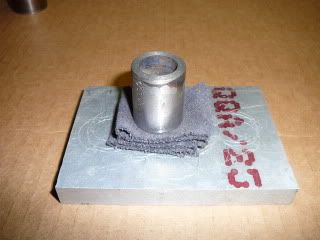

I did a post some time ago showing some pictures of my patch cutting system. Here it is.

Simple and efficient with no ragged edges to contend with. I keep all my ball patches pre-lubed in plastic topped pill bottles with cold weather windshield washer fluid. It works very good in all temperature conditions. It is nothing more than liquid soap, water and alcohol, all very good fouling cleaners.. Mike D.

Simple and efficient with no ragged edges to contend with. I keep all my ball patches pre-lubed in plastic topped pill bottles with cold weather windshield washer fluid. It works very good in all temperature conditions. It is nothing more than liquid soap, water and alcohol, all very good fouling cleaners.. Mike D.

- Joined

- Jan 3, 2013

- Messages

- 20,091

- Reaction score

- 1,018

I made my own rotating cutter that goes in my drill press, it works so-so. For years I just bought them (much easier). I think a punch would work better.

hmmmm? I got a five dollar reward at O'Reily was wondering what to do with!

awebbersr

40 Cal.

For 50 & 54 cal I use a 50 cent piece, draw around it and cut. For 45 I use a quarter. :thumbsup:

Thats the same system I use. I purchased mine from Ohio Ramrod. All works well.

Similar threads

- Replies

- 23

- Views

- 888