...I am interested in making tools for building traditional fowling gun barrels. Information seems to be lacking on the boring bench though. Has anyone built one and would be willing to provide photos or details?

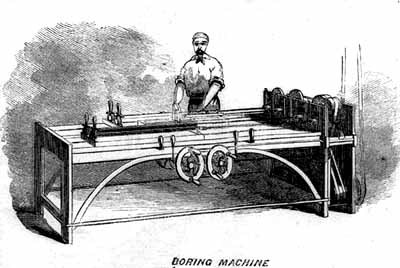

I have a question as to what you mean by "boring". Back in the 18th, and probably into the 19th, century the use of the term "boring" was what we would call reaming today. Barrels back then were forge welded with strips of iron around a mandrel. The mandrel formed the hole through the barrel or the bore. The barrel would be straightened by sighting down the bore. Then in would be placed in the boring bench and reamed with long reamers. The reamers were changed out to slightly larger sizes until the desired bore size was achieved.

For fowler barrels, the exterior dimensions including the octagon section and the round section were ground to shape against large grinding wheels in the large boring mills and probably filed to shape in small shops.

The modern term "boring" generally means drilling a long hole. For gun barrels this is usually done on special deep hole drilling or gun barrel drilling machines with special drill bits that are hollow for the circulation of cooling, lubricating, and chip clearing fluid.

Which type of boring are you referring to?

Steve Bookout of Toad Hall Rifle Shop retired several years ago. It does look like his website had been taken down.

His friend, Hoot Al, still has a website and still offers for sale the Rifling Book that he helped Steve Bookout write. Here is a link to it.

http://www.hootalrifleshop.org/purveyors_links.htm

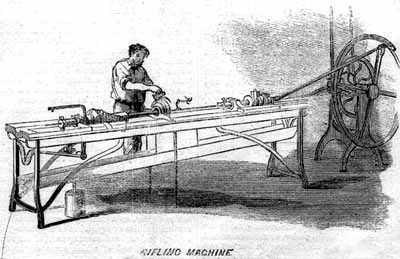

This book is primarily for building a rifling machine, which isn't needed for fowler barrels. I don't know for sure, but it might cover the reaming process because I know that Bookout used to hold classes on how to hand forge a barrel, and he probably included the rest of the process to rifle it. You could contact Hoot Al and see.