coehornboy

40 Cal.

- Joined

- Mar 24, 2005

- Messages

- 218

- Reaction score

- 1

The following links are to photos of a cannon I built, called “Little Bill.” Formerly known as a “32-pdr Bureau shell gun of 4500#,” it looks like a Dahlgren. A total of 379 of these guns were made between 1864 and 1867, and a total of 91 still survive. The original, Big Bill, number 333 of the series, was placed on the USS Kearsarge at the Boston Navy Yard in December 1867, where it was fired 54 times up to 1870, probably all in practice. It was off loaded at Mare Island Navy Yard, California, in October 1870, and remained there in inventory. The final disposition of the gun is noted in government records as “Loaned to Fred Steele Post G.A.R. (Grand Army of the Republic) #70, San Luis Obispo, CAL Feb’y 1892.” It can be currently seen at the G.A.R. Plot at the SLO cemetery.

The project of building “Little Bill” was a true learning experience, especially for someone who has no formal training as a welder, artisan, or machinist. I decided to build a “representation” of Big Bill, as opposed to an exact scale replica of the gun. This allowed me some artistic freedom regarding various details. I also decided that the replica had to be of a manageable size and be fully functional. The gentleman that restored the cannon in the ”˜90's, Ed Strobridge, provided me with a collection of photos and drawings. I determined that the scale of the cannon would be based upon the size of stock that was readily available from a local steel wholesaler.

A three foot long billet of cold rolled steel, seven inches in diameter, was purchased at a cost of $278 (December 1998 prices!!). The billet weighed 393 pounds. Based upon the diameter and length of the billet, the overall scale of the cannon was determined, and the adjusted measurements were transferred to a sketch of the barrel (1/3 scale...the original is 9' long).

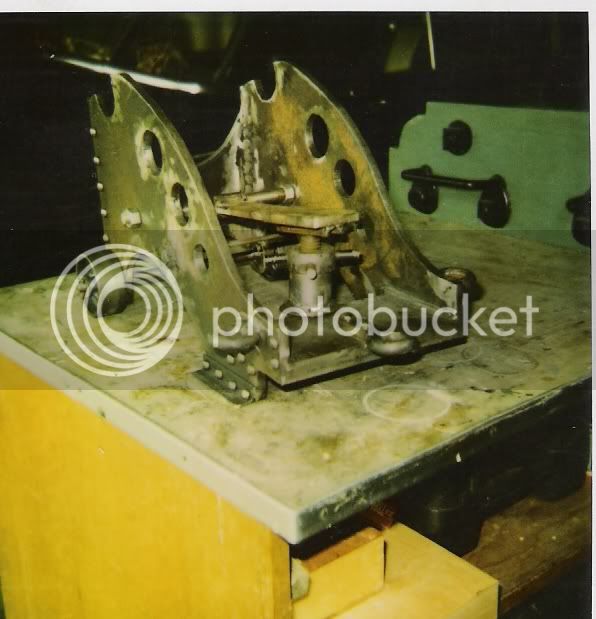

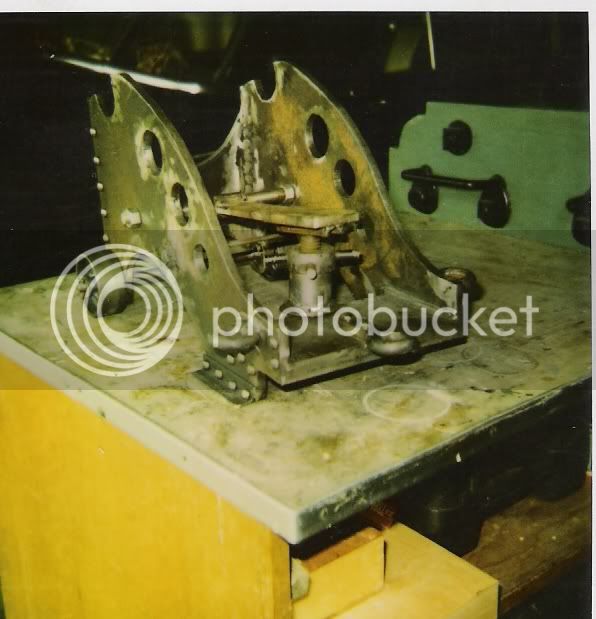

Next, a template of the side of the carriage was made out of plywood. This shape was transferred to steel plate, and cut out with an oxy-acetylene torch. The pieces of steel plate were welded together for strength. The detail was added to the carriage. This included decorative rivets, the two rear skids, trunnion caps and bearing surfaces, as well as the screw mechanism. After a long search, scale steel wheels were found at a hand truck supply company in San Francisco.

The carriage was completed by Spring of 1999. However, not knowing how to use a lathe, I was at the mercy of the part-time machinis. I soon lost interest, and the project was shelved for approximately two years. In the Spring 2001, work resumed on the barrel. The machinist started by first boring the billet, and planned to later shape the outside of the tube to ensure that the bore was on center. The plans called for a bore diameter of 1.5 inches, however, the machinist assumed that I wanted to use the same reamer as I had on a previous project (coehorn mortar), and the tube was bored to a larger, 2.6 inch diameter. Based upon the larger bore diameter, the outside dimension of the barrel was also adjusted. As a result, the trunnion had to be welded on closer to the muzzle end of the barrel (forward approximately two inches) in order to balance the barrel.

In Spring of 2001, Little Bill made his debut. Based upon the diameter of the bore, two different projectiles were made, the first being tennis balls filled with concrete, and the second being soda cans filled with concrete. Based upon the experience of other large-bore cannon shooters, an initial charge of 400 grains of black powder was loaded in the barrel, followed by the concrete filled tennis ball projectile. The first attempts resulted in misfires. A quick examination of the barrel tube revealed the problem; the barrel, made to scale plans, contained a large powder chamber in the breech. This, combined with the angle of the fuse hole (again, from the scale plans), required a much larger powder charge to ensure ignition. After trial and error, a charge of 1,200 grains of black powder was sufficient to send a projectile 200 yards downrange.

The concrete filled tennis ball proved to be too light of a projectile, which resulted in erratic flight. The concrete filled soda cans proved to be the best projectile.

In the Spring of 2002, the SUVCW, Department of California and Pacific, held its 116th annual encampment in San Luis Obispo, California. In honor of the event, Little Bill was transported to the GAR plot, where he was photographed next to the restored Big Bill.

I share this with all of you, and, hopefully, you will feel inspired to try making a project like his on your own (as I previously said, I have no formal training or experience in any technical arts).

P.S.: I have built two other cannons, which I will post here soon..

The project of building “Little Bill” was a true learning experience, especially for someone who has no formal training as a welder, artisan, or machinist. I decided to build a “representation” of Big Bill, as opposed to an exact scale replica of the gun. This allowed me some artistic freedom regarding various details. I also decided that the replica had to be of a manageable size and be fully functional. The gentleman that restored the cannon in the ”˜90's, Ed Strobridge, provided me with a collection of photos and drawings. I determined that the scale of the cannon would be based upon the size of stock that was readily available from a local steel wholesaler.

A three foot long billet of cold rolled steel, seven inches in diameter, was purchased at a cost of $278 (December 1998 prices!!). The billet weighed 393 pounds. Based upon the diameter and length of the billet, the overall scale of the cannon was determined, and the adjusted measurements were transferred to a sketch of the barrel (1/3 scale...the original is 9' long).

Next, a template of the side of the carriage was made out of plywood. This shape was transferred to steel plate, and cut out with an oxy-acetylene torch. The pieces of steel plate were welded together for strength. The detail was added to the carriage. This included decorative rivets, the two rear skids, trunnion caps and bearing surfaces, as well as the screw mechanism. After a long search, scale steel wheels were found at a hand truck supply company in San Francisco.

The carriage was completed by Spring of 1999. However, not knowing how to use a lathe, I was at the mercy of the part-time machinis. I soon lost interest, and the project was shelved for approximately two years. In the Spring 2001, work resumed on the barrel. The machinist started by first boring the billet, and planned to later shape the outside of the tube to ensure that the bore was on center. The plans called for a bore diameter of 1.5 inches, however, the machinist assumed that I wanted to use the same reamer as I had on a previous project (coehorn mortar), and the tube was bored to a larger, 2.6 inch diameter. Based upon the larger bore diameter, the outside dimension of the barrel was also adjusted. As a result, the trunnion had to be welded on closer to the muzzle end of the barrel (forward approximately two inches) in order to balance the barrel.

In Spring of 2001, Little Bill made his debut. Based upon the diameter of the bore, two different projectiles were made, the first being tennis balls filled with concrete, and the second being soda cans filled with concrete. Based upon the experience of other large-bore cannon shooters, an initial charge of 400 grains of black powder was loaded in the barrel, followed by the concrete filled tennis ball projectile. The first attempts resulted in misfires. A quick examination of the barrel tube revealed the problem; the barrel, made to scale plans, contained a large powder chamber in the breech. This, combined with the angle of the fuse hole (again, from the scale plans), required a much larger powder charge to ensure ignition. After trial and error, a charge of 1,200 grains of black powder was sufficient to send a projectile 200 yards downrange.

The concrete filled tennis ball proved to be too light of a projectile, which resulted in erratic flight. The concrete filled soda cans proved to be the best projectile.

In the Spring of 2002, the SUVCW, Department of California and Pacific, held its 116th annual encampment in San Luis Obispo, California. In honor of the event, Little Bill was transported to the GAR plot, where he was photographed next to the restored Big Bill.

I share this with all of you, and, hopefully, you will feel inspired to try making a project like his on your own (as I previously said, I have no formal training or experience in any technical arts).

P.S.: I have built two other cannons, which I will post here soon..