Hi,

American black walnut is quite different than

Juglans regia (aka English, French, Italian, Turkish, Armenian, Circassian, European walnut) and is usually less dense. I build many British military guns but often have to use black walnut for the stocks because long blanks of English walnut are hard to find and very expensive. So I have to bite the bullet, use black walnut and make it look like the English species. While you can find black walnut with beautiful warm reddish tones, it often has a cold purplish brown color that I dislike. So I warm it up with yellow dye.

That brings out warm and redder tones in black walnut.

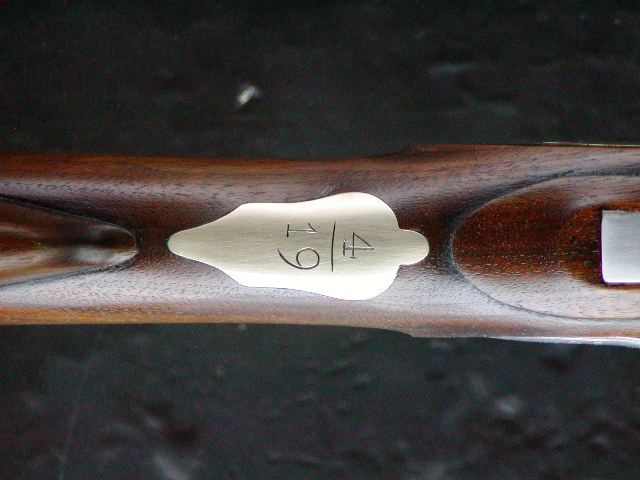

This shows a piece of black walnut with just finish on it compared with black walnut stained to look like English walnut.

On these muskets, the black walnut is simply finished with a tung oil based varnish that mostly fills the pores but not completely like British muskets of the era. However, it still is a bit shiny again as were the original guns.

dave