druid said:

A cautionary note though...If you are going to create items that are meant to be historically correct, you will have to forgo any kind of man-made metal stamps, snaps or rivets, in favor of rudimentary carving techniques and lace thongs and toggles/PC buttons.

Even your sewing medium will have to be selected appropriately. Using sinews made from animal tendons [deer/elk mostly] should be used [or cotton linen thread], avoiding "artificial sinew" or other nylon threads. If you don't care about HC, then artificial sinew and copper rivets with burrs are perfect.

I'm sorry and not sure where you got your info but other than the synthetic thread and snaps mentioned all of the above were used in period dependent on the type of work done and by whom - pro or amateur.

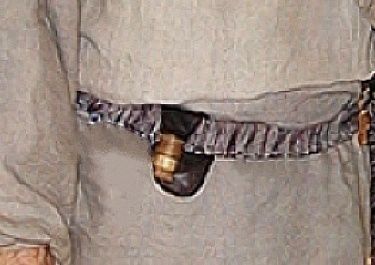

1) Rivets with burrs have been used since the Romans - here's a sheath dated 1840 made with rivets:

2) Carving - period pieces show carving in many grades, including rudimentary, but also very fine work.

3) Lacing - seldom used by pros other than the Spanish. Most lacing seen was on original work was done by amateurs or as field expedient repair.

4) Thread - yep real sinew (when doing frontier or Indian goods), other than that linen or hemp thread were the most common until the 1830's when cotton thread became more common, but of the three the cotton is has the least strength where as hemp is the strongest vegetable fiber with linen closer to hemp. I mostly use Barbour's Red Hand or Fils aux Chinois linen thread or a good quality hemp thread from various period vendors. I tried to use the hemp cord available at Wally World but it is of fairly low quality. For weights I generally use 3 cord or 5 cord Barbours dependent on the product.

Regarding leather and as noted it will depend on what type bag your making:

1) re: Oil Tan - this is not a true oil tan in the trade is known as oil re-tan i.e. it is a chrome tanned leather that then goes through a an oil process.

2) Veg/bark/Oak Tan: This the traditional cowhide tanning method used for the great bulk of period shot pouches, especially the commercial/pro made ones.

HC/PC - if this matters than your bags should be made from:

1) veg tanned cowhide, the most commonly available material.

2)Veg tanned deer or elk hide - a period correct tannage, but expensive since it's a boutique/specialty tannage and not a commercial one.

3)True oil tan - The German tanned deer hides from Crazy Crow are the same oil tannage as used back when. In fact German tan is the method used for the vast majority of the leather breeches. A great alternative to real brain tan at a less expensive price.

4) Brain tan elk or deer - if making a native or native inspired bag. Expensive since again it is supplied only by small boutique/specialty vendors.

5) Commercial elk and buck skin - chrome tanned

FYI - chrome tanned leather was not developed until the 1860's and was not produced commercially until the 1880's.

Dealer recommendations - FWIW I've been a pro leather crafter since 1971 and t was my full time job for the last 18 years so these are my observations based on that experience:

1) Tandy - like many I used Tandy when beginning and for many years after, but starting in the 1980's their quality began to suffer and I've used some since than but 8 out of 10 times I had to return it. IF you have experience or not some one who does and you can go to the store to go through their stacks, then go for it, but if you have to buy via mail then there are better options, especially since their prices are often higher than other suppliers.

2) My favorite for the last 10 years: RJF Leather. This some of the finest veg tan I've ever used. Reportedly it is old time pit tanned with oak from Portugal. Roger is the man. I mostly use his doeble shoulders which run around 13 s/ft, IMO the best buy for the buck, although he sells full side as well for those who may need a larger piece. Like most dealers it comes in 3 grades (the grades vary in name from tannery to tannery) A, B, & C or 1, 2, 3. You order from Roger, he sends the leather and an invoice.

2) Wickett & Craig - buy direct from the tannery. When I use this brand I get the saddle tan rather than the craft tan since the saddle tan is a bit oilier. They generally only sell sides of around 22 s/ft so for the hobbiest they may not be the best. Also you can buy thicker sides and have them split which gives you an almost perfect back side.

3) Herman Oak you can buy from the tannery but there is a 10 side minimum. On the other hand there are several outlets such as Montana Leather who sell HO. Great leather used by a plethora of saddle makers.

leather weight: Leather is sized by it's thickness and or weight. The ounce measurement so often seen is based on the old method of weighing a one square foot piece of the leather. Today it has a thickness equivalent: 1 oz = 1/64" so just multiply the ounces times 1/64" (.016") to get your thickness.

For those folks to whom PC/HC is important than the most commonly used weight of cowhide was 3/4 oz. On the other hand 4/5 can be used IF the weight is closer to 4 oz and yes 3/4 oz is MORE than strong enough and generally holds it shape well.

For softer leather like elk or deer one need to pre-stretch it. Dampen thoroughly, let any excess drip off, then stretch - FWIW - I use a plywood backing and nails to stretch and let it hang/dry for at least 48 hours. The thinner hides like deer may need some type of lining, but elk and German tan (Euro red deer similar to out elk/wapiti) are generally thick enough to hold up well as long as pre-stretched.

Hope that helps

and yes there are several other suppliers such as Ky Leather and Sprinfield Leather that sell good quality leather, but I prefer the ones listed since I KNOW the quality is good.

For sheath and holsters: the industry standard since the late 1800's has been 8/9 oz veg tan although on many period pieces 7/8 oz was used and on the el cheapos of the period 5/6 oz (often called chicken skin holsters in the late 1800's). Just how thick for sheaths will depend on blade length - for blade up to 4" I use 5/6 oz, 5-9" 8/9 oz, and anything bigger 10/11 oz. For period side center seam sheaths 5/6 or 6/7 works great.

any way as always other mileage will vary.....

PS for wax I use a 60/40mix of beeswax and rosin - a simplified version of coad (Greg G will know what I'm talking about). With the added rosin it makes the thread sticker and helps lock the thread in place, plus rosin is an anti-fungal/bacteria so it helps preserve the thread.

For needles : Harness needles - I like the John James or Osborne brands best. For three cord I use a #2 needle and for 5 cord a #0 needle.

A little trick - take a larger needle such as a 00 and mount in a handle to use a fid to open up holes if need by when back stitching. And yes I agree with Artificer - if you're going to sew leather get a copy of that book, but also take a lool at the videos by Nigel Armitage, a master British crafter.

:wink:

:wink: