Skychief

69 Cal.

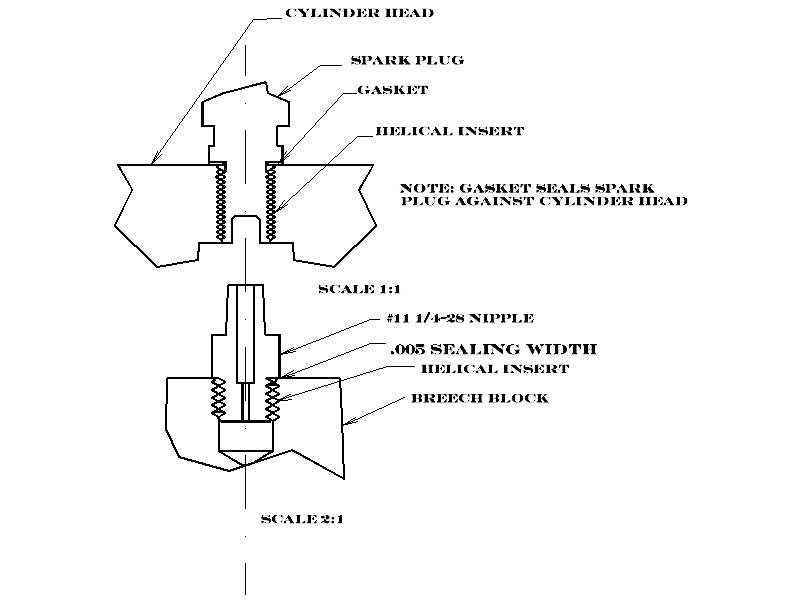

I'm on the hunt for a few nipples for a Royland Southgate rifle.

Overall length: .662"

Diameter across the threads: .248"

Diameter of shoulder: .310"

Length of shoulder: .194"

Threaded section length: .205"

Length of cone: .257"

The overall length is accurate, while the other lengths are within a thousandth or two (hard to measure).

I believe the nipple has 28 threads per inch. Will confirm this soon.

Can ANY of you tell where suitable replacement nipples be ordered? Would prefer not to drill and tap if it can be avoided.

I've looked a few places but come up empty.

Thanks for ANY suggestions. Will be back with definitive TPI measurement.

Best regards, Skychief

Overall length: .662"

Diameter across the threads: .248"

Diameter of shoulder: .310"

Length of shoulder: .194"

Threaded section length: .205"

Length of cone: .257"

The overall length is accurate, while the other lengths are within a thousandth or two (hard to measure).

I believe the nipple has 28 threads per inch. Will confirm this soon.

Can ANY of you tell where suitable replacement nipples be ordered? Would prefer not to drill and tap if it can be avoided.

I've looked a few places but come up empty.

Thanks for ANY suggestions. Will be back with definitive TPI measurement.

Best regards, Skychief