- Joined

- Feb 26, 2008

- Messages

- 833

- Reaction score

- 14

Surfing around on some gun auction site, I stumbled over a "description" saying:

.50 Hawken, can't find makers name on gun ,Has 32" barrel :grin: with very good bore :grin: , metal finish brown and worn :rotf: Has no ramrod :idunno: . Cracked stock at toe :hmm: . Price was low,too.

,Has 32" barrel :grin: with very good bore :grin: , metal finish brown and worn :rotf: Has no ramrod :idunno: . Cracked stock at toe :hmm: . Price was low,too.

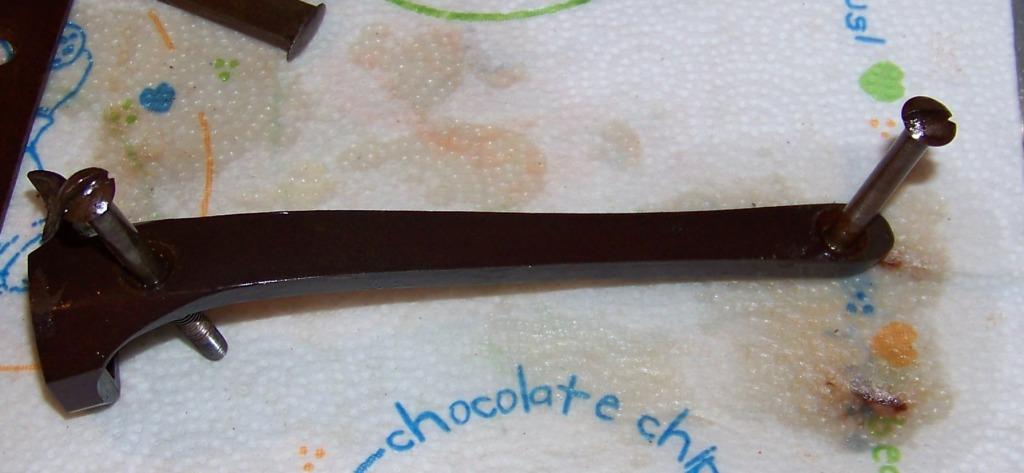

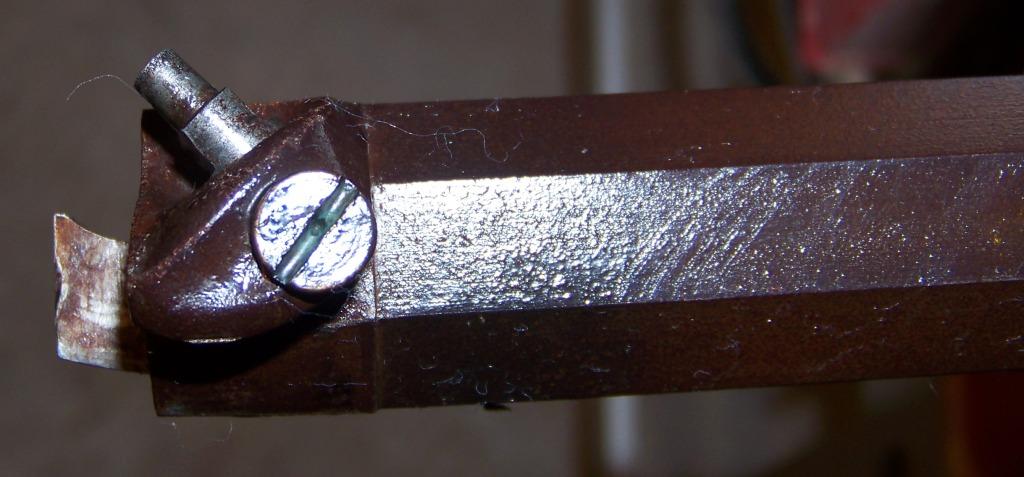

First picture I thought about another CVA, but upon closer picture inspection I saw a correct drum on a patent breach and a long barrel tang as well :wink: ,an older style hawken lock similar than on a friends Hawken which was buildt to the original plans in the 60ies :grin: , the ramrod thimbles appear to be soldered to the underrib and not screwed on like with the cheap copies and the trigger guard is steel as is the buttplate and toe plate.:grin: Everything is deeply browned and needs definately to see some oil. I got the rifle for $5 more than the minimum bid and hope to get it sometimes next week. Since the maker was not visible,I will pull the barrel and hope to find the barrel maker on the bottom where it belongs :grin: I hope for a Douglas or? The crack in the toe is not bad,because I will shorten the stock anyways to my preferred LOP.

Look here:

.50 Hawken, can't find makers name on gun

First picture I thought about another CVA, but upon closer picture inspection I saw a correct drum on a patent breach and a long barrel tang as well :wink: ,an older style hawken lock similar than on a friends Hawken which was buildt to the original plans in the 60ies :grin: , the ramrod thimbles appear to be soldered to the underrib and not screwed on like with the cheap copies and the trigger guard is steel as is the buttplate and toe plate.:grin: Everything is deeply browned and needs definately to see some oil. I got the rifle for $5 more than the minimum bid and hope to get it sometimes next week. Since the maker was not visible,I will pull the barrel and hope to find the barrel maker on the bottom where it belongs :grin: I hope for a Douglas or? The crack in the toe is not bad,because I will shorten the stock anyways to my preferred LOP.

Look here: