Wife got me the Traditions Kentucky Kit for Christmas. This is my first "traditional" style muzzle loader. My black powder experience before this has been limited to cap and ball pistols. I want to build a "Nice" southern mountain style long rifle but I didn't want to drop the coin to build a high quality setup as my first muzzle loader and possibly screw it up. I thought the Kentucky Rifle kit would be a good introduction to the processes, tools, and skills I will need to build my own rifle. I took some pictures while I was building and thought I would share my experience with the kit.

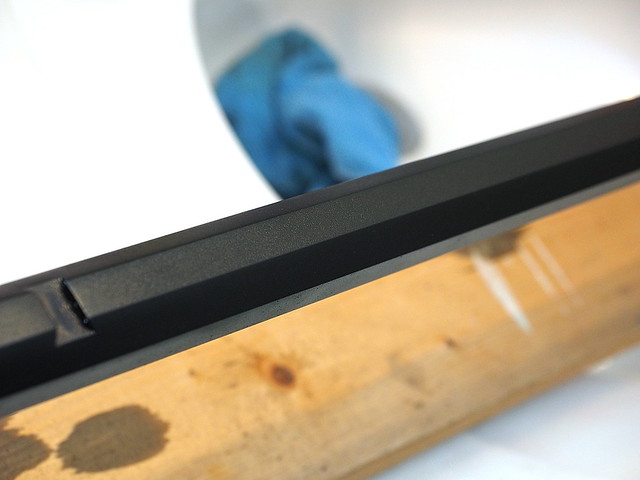

First thing I did was (attempt) to dry fit all of the parts. The lock didn't come close to fitting in the cutout on the stock. I lined up the holes through the stock through the lock to get an idea where I needed to removed material. I had to remove material on both of the front and rear of the inletting. If I had just tried to wedge in one side and only remove material on the opposite side it would have left the lock unaligned to the holes in the stock. You can see the part I screwed up because I started at first with a Dremel and sanding disc. It was going just fine until I started to sneeze and tried to pull the tool away too quick and buggered up the inletting a little. Learning from my mistake I quickly discarded the dremel and finished with 220 grit wrapped around the end of a pencil. It gave me much more control. So it took me 10 minutes to work an area instead of 1 minute. I learned an early lesson on patience and the dremel will never get near my work ever again.

I did force press the lock into the inletting at one point and it caused a little chip to come out of the corner of of the stock. Lesson #2. Don't force things. I worked the material until the lock would easily press into place with just enough clearance that you can gently press it in but it still hold itself in place if let go.

First thing I did was (attempt) to dry fit all of the parts. The lock didn't come close to fitting in the cutout on the stock. I lined up the holes through the stock through the lock to get an idea where I needed to removed material. I had to remove material on both of the front and rear of the inletting. If I had just tried to wedge in one side and only remove material on the opposite side it would have left the lock unaligned to the holes in the stock. You can see the part I screwed up because I started at first with a Dremel and sanding disc. It was going just fine until I started to sneeze and tried to pull the tool away too quick and buggered up the inletting a little. Learning from my mistake I quickly discarded the dremel and finished with 220 grit wrapped around the end of a pencil. It gave me much more control. So it took me 10 minutes to work an area instead of 1 minute. I learned an early lesson on patience and the dremel will never get near my work ever again.

I did force press the lock into the inletting at one point and it caused a little chip to come out of the corner of of the stock. Lesson #2. Don't force things. I worked the material until the lock would easily press into place with just enough clearance that you can gently press it in but it still hold itself in place if let go.