-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The ideal patch knife.

- Thread starter Joe Yanta

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dale Brown said:I could see it if the question was, "Is a patch knife necessary", but even then, you should explain why and not just say NO.

I guess I see so many helpful replies here that this one just struck me as counter productive. The guy wants to make a knife and he's told to forget it. :shake:

I am sure that Joe Yanta will make the connection and give any negative answer the merit it deserves as he sees fit...

Swampman may have very well came to the stage in his hobby that a patch knife is no longer a highly sought after item, don't know, perhaps he should have offered a reason as to why he feels a patch knife is no longer needed as a sort of point/counter-point analogy to his reply...

Alas, he didn't...

Hey Joe, given the specific nature of a "Patch knife" I've decided that, for me at least, the blade edge must be straight or concave, and thin enough to take an ultra-sharp edge.

IMO, Straight razors blades make excellent patch knives, but one of the most intriguing, albeit ugly, designes I've seen was from an old hacksaw blade. The design was in muzzleloader Mag many years ago, so I'm relying heavily from memory here.

Hope this helps

IMO, Straight razors blades make excellent patch knives, but one of the most intriguing, albeit ugly, designes I've seen was from an old hacksaw blade. The design was in muzzleloader Mag many years ago, so I'm relying heavily from memory here.

Hope this helps

Deadeye said:I like the small ones with the blunted point, have one on the front and under the flap of each shooting bag

Except for the top one I see you also like that little "Possum" Norwegian carbon-steel blade from Brusletto. I have one of these stuck in a spike antler that I aged by wrapping it in mustard soaked gauze. Came out a little more aged than I had intended, but it still holds a shaving edge.

I used the "Camper" version (3-1/2") in the image posted earlier. Just cannot beat the quality of the steel for the price (under $10!).

Come to think of it, I guess every knife in the image below has been used to cut a patch (the little "Possum" knife is at top near the hawk head)

Why do people look down their noses at these Norwegian blades? I've got a neck knife that is Sharp enough to shave with, and can almost be sharpened on the back of my hand; I love it!

However, I've heard several people make oblique comments about its authenticity.

However, I've heard several people make oblique comments about its authenticity.

I don't know of anyone who discredits their qualities, just their "authenticity". That knife on the bottom in my photo is a Helle Polar I wear as a neck knife and it is otherworldly sharp. I had one fellow hunter tell me I was knuts to wear it on mt chest as he thought it would slice through the sheath without hesitation. (It's boiled pigskin inside of deerskin, I'm comfortable with it).

I stopped using it as a patch knife because I went into my purpleheart ball-block before I realised it and prior to that had shaved thin pieces off my walnut block. :shocked2:

They make a big knife (8-1/2" blade) that I have been eyeing for years, but it only comes in stainless. Järvenpää (there's a mouthful) makes one for the Saami (Lapps) in black carbon steel but it's "only" 7" and I'm about convinced I need that one.

I stopped using it as a patch knife because I went into my purpleheart ball-block before I realised it and prior to that had shaved thin pieces off my walnut block. :shocked2:

They make a big knife (8-1/2" blade) that I have been eyeing for years, but it only comes in stainless. Järvenpää (there's a mouthful) makes one for the Saami (Lapps) in black carbon steel but it's "only" 7" and I'm about convinced I need that one.

It is not uncommon for the "authenticity" factor to be introduced into a topic, which is probably a good thing for those who may think they are planning to make something that was use in the past, once they have the facts they can proceed down either path they choose, but it will be an educated choice.Many myths and misconceptions will continue if no one will point to the truth.

rich pierce

70 Cal.

I don't want to get into an argument and I have no beef with Norwegian blades. I can give you my personal reasons why I would not choose a Norwegian blade for a patch knife, but I didn't start this and have no dog in the fight. First off I don't buy blades but that's indendent of who makes them or the style.

OK- onto specifics:

In general, smaller and thinner period knives are tapered evenly from the back to the edge, like a filet knife does or many a butcher knife does still. Even "riflemen's knives" of the period often display this feature, though they were large. This is a common feature of many (but not all!) hand forged blades. (I know, Bowies and all....)

The smaller Norwegian blades I have seen that people use for patch knives have the "stock removal" look- the blade looks as though it is of uniform thickness from the back to near the edge, then it is hollow ground. The other thing is the shape, if I can be so bold. They have a "sticker" look regardless of size. Seems like every blade they make is just a scaled down version of the next bigger size. Small knives are often used for different purposes than large knives and thus often have a different shape.

Last but not least, I like at least one side of my patch knife to have a flat edge becaise it slides across the muzzle correctly.

But I hear they cut good and can be had cheaply.

OK- onto specifics:

In general, smaller and thinner period knives are tapered evenly from the back to the edge, like a filet knife does or many a butcher knife does still. Even "riflemen's knives" of the period often display this feature, though they were large. This is a common feature of many (but not all!) hand forged blades. (I know, Bowies and all....)

The smaller Norwegian blades I have seen that people use for patch knives have the "stock removal" look- the blade looks as though it is of uniform thickness from the back to near the edge, then it is hollow ground. The other thing is the shape, if I can be so bold. They have a "sticker" look regardless of size. Seems like every blade they make is just a scaled down version of the next bigger size. Small knives are often used for different purposes than large knives and thus often have a different shape.

Last but not least, I like at least one side of my patch knife to have a flat edge becaise it slides across the muzzle correctly.

But I hear they cut good and can be had cheaply.

Hey Rich, thanks for the enumerated critique, that's what I've been waiting for. :thumbsup:

I agree with you about the bevelled edge, I don't really care for it either.

I was given my knife by a very close friend when I left the Marine Corps, so I treasure it for that as much as anything else.

All I've ever heard is that these blades are not "Authentic" but no one ever stated a clear reason for the inauthenticity.

Appreciate you taking the time to elaborate :thumbsup:

I agree with you about the bevelled edge, I don't really care for it either.

I was given my knife by a very close friend when I left the Marine Corps, so I treasure it for that as much as anything else.

All I've ever heard is that these blades are not "Authentic" but no one ever stated a clear reason for the inauthenticity.

Appreciate you taking the time to elaborate :thumbsup:

Not just knives, I kind of like their skis and rifles, too. Took two deer with a Sako barreled M-39 this past season.

As I said though, it is not my choice for a patch knife. I don't even carry it when m/l anymore. I've gutted out half-a dozen deer with that little 2-3/4" blade and it is great for that. :winking: Yes, it is stock removal. It is a 1/16" high carbon (brittle) steel laminated between two carbon steel layers.

Forge me a full-tang one like that and mount it in a hardwood handle with sheath for $40 and we'll talk. :winking: I much prefer my forged knives, but they are no better at cutting than the ground edge modern variety.

As I said though, it is not my choice for a patch knife. I don't even carry it when m/l anymore. I've gutted out half-a dozen deer with that little 2-3/4" blade and it is great for that. :winking: Yes, it is stock removal. It is a 1/16" high carbon (brittle) steel laminated between two carbon steel layers.

Forge me a full-tang one like that and mount it in a hardwood handle with sheath for $40 and we'll talk. :winking: I much prefer my forged knives, but they are no better at cutting than the ground edge modern variety.

Guest

What about the many knives described in "Firearms, Traps and Tools of the Mountain Men" by Carl P. Russell?

CP

CP

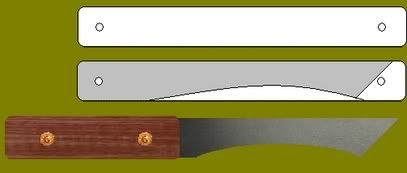

While not PC, my favorite patch knife is one I made recently from an old planer blade. I shaped it on a belt sander and made a handle for it out of the base section of a small whitetail antler. The blade section is about 3", with a bevel on one side only. The flat side of the blade glides across the muzzle or loading block without digging in. I left the end square. The knife takes and holds a razor edge. Works like a charm. Now I need to make a varnished rawhide sheath for it.

You fellas have some really good knives and opinions on knives here. Thinking more about what you have shown and talked about here I dont think the Nessmuk is what I am looking for. It seems like the patch knife is about as a personal decision as one can get.

I kinda like the profile of the Green River patch or paring knife with the almost squareish blunt tip. I like the thin blade of making one out of a hack saw blade too.

Keep your ideas coming, I think this is very interesting.

All of you comments and opinions are appreciated and respected. Thanks

Joe Yanta

I kinda like the profile of the Green River patch or paring knife with the almost squareish blunt tip. I like the thin blade of making one out of a hack saw blade too.

Keep your ideas coming, I think this is very interesting.

All of you comments and opinions are appreciated and respected. Thanks

Joe Yanta

Yep, Stumpy, your right ,all except the striker knife are Norwegian but they're not laminated,

the 3.5" use just the center piece of very hard steel without the laminations. There's no sawing action when cutting a patch. The blade is so sharp it just moves thru the patch like it wasn't there. I made that bottom one 35 yrs. ago. Have gutted a few deer with it but usually have another knife for that. The rounded tip is good for splitting the belly without cutting the stomach.

the 3.5" use just the center piece of very hard steel without the laminations. There's no sawing action when cutting a patch. The blade is so sharp it just moves thru the patch like it wasn't there. I made that bottom one 35 yrs. ago. Have gutted a few deer with it but usually have another knife for that. The rounded tip is good for splitting the belly without cutting the stomach.

Guest

Swampman said:I wasn't being negative. I was trying to be helpful. Not using a patch knife really speeds up your loading process, and it is historically correct. One less thing to carry. :winking:

Simplify is my motto!

In keeping with your other comments about doing things the "old" way, how do you make your patches? Do you cut patches prior to using them? Or do you make an exception in this case and purchase "modern" pre-cut patches?

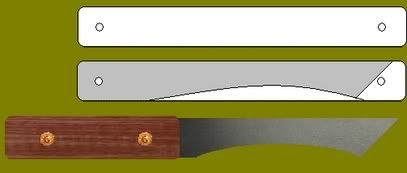

A good source of patch knife material is from bandsaw blades, specifically those used in the lumber sawing mills. I occassionally break a blade and rather than throw them in the trash, they go into a (I'll reuse it later for another purpose bin). The blades I use are 0.042" thick and measure 1" from tooth gullet to back edge, leaving plenty of room for shaping with a grinder or belt sander. I then put a sharp straight chisel edge on the blade with the planer blade sharpening machine but this can be done with a wide belt sander using fine grit.

[/img]

[/img]

Good luck with the blade making

Good luck with the blade making

Similar threads

- Replies

- 1

- Views

- 269

- Replies

- 17

- Views

- 973

- Replies

- 14

- Views

- 993

- Replies

- 5

- Views

- 815

- Replies

- 0

- Views

- 366