-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

patch cutter

- Thread starter Griz

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I use the "converted hole saw" method, probably used by many on the Forum. Obtain a hole saw of the proper diameter, and some hardwood blocks. Select a block about 1/2 - 3/4" thick and drill a hole in it with the new hole saw. Do this before the next step, which is to remove the teeth from the saw. The hole drilled with the teeth will be just a tiny bit larger than the body of the saw without the teeth, which allows clearance through the block when cutting patches. Remove the teeth from the saw by grinding them off, making an effort toward keeping the new edge uniform and level. Grind a bevel on the outside to as sharp as you can get it and then sharpen some more with a stone. As visible in the photo, I glued sandpaper on both the base block and the hold down block, to assist in holding the cloth from spinning. This method will cut through 5-6 layers of ticking like poop through a goose and will probably do more if you are impatient. This method works best with a drill press, however it may work with a hand drill. I have never tried it that way.

There's absolutely no law against using square patches. Some original bags have square patches threaded together on a string so you can just pull one off the stack as needed.

I have used both and my rifles seem to hold a tighter group with a small round patch. 1-1/8" for a .50 gave me the best groups. When I went to a bigger patch or a square patch my POI went wild. I do know that in some rifles a square patch will work great, I just haven't had luck with them in mine. If it is weird I own it.

Guest

Griz says:"If it is weird I own it."

Better'n me! If it's wierd I MARRIED IT!!!!

Better'n me! If it's wierd I MARRIED IT!!!!

I use a rotary cutter from Walmart. In the sewing section, get the large 60mm cutter, a 36" cutting mat & the wide 36" clear ruler all in the same section.

You can lay out the material to just over 36" & cut 8-10 layers at a time & cut over 10,000 1" patches in about 15 minutes.

In an hour I cut more patches in 1", 1 1/4", 1 1/2" and 1 3/4" than I can shoot in 2 years.

BE VERY CAREFUL with this rotary cutter. If will flat slice you to the bone in nothing flat. I got the one with a locking guard as when I went there to look at them one was laying out & I picked it up not knowing it was unlocked & proceeded from there directly to the pharmacy for a bandaid ! But anyway, with this one when I am done with it I can lock it & put it back in the package it came in.

I have shot them square cut & round for years & really cannot tell a difference in them. However, one time I used a Snickers wrapper for a shotgun wad too & it didn't show any difference in my shooting, other than making the shot more colerful by the confetti decoration ! ha ha !

You can lay out the material to just over 36" & cut 8-10 layers at a time & cut over 10,000 1" patches in about 15 minutes.

In an hour I cut more patches in 1", 1 1/4", 1 1/2" and 1 3/4" than I can shoot in 2 years.

BE VERY CAREFUL with this rotary cutter. If will flat slice you to the bone in nothing flat. I got the one with a locking guard as when I went there to look at them one was laying out & I picked it up not knowing it was unlocked & proceeded from there directly to the pharmacy for a bandaid ! But anyway, with this one when I am done with it I can lock it & put it back in the package it came in.

I have shot them square cut & round for years & really cannot tell a difference in them. However, one time I used a Snickers wrapper for a shotgun wad too & it didn't show any difference in my shooting, other than making the shot more colerful by the confetti decoration ! ha ha !

My "Chief-of-Staff" has been making very fine quilts for years and has more darn high tech quilting equipment than I have rifles and hunting[url] equipment...in[/url] fact, a couple of my muzzleloaders were sympathy purchases after she bought the latest and greatest robotically controlled, electric start super-duper quilting machine apparatus that took me a day to set up !!

She has a cutting table & board with rotary cutters set up on a table in that room and every now and then if she has some leftover cotton or flannel material, she'll cut out a couple hundred cleaning patches in the blink of an eye.

Just this weekend I tried to get her to make some out of an old flannel nightgown but she wouldn't take it off!

::

She has a cutting table & board with rotary cutters set up on a table in that room and every now and then if she has some leftover cotton or flannel material, she'll cut out a couple hundred cleaning patches in the blink of an eye.

Just this weekend I tried to get her to make some out of an old flannel nightgown but she wouldn't take it off!

::

Last edited by a moderator:

RussB

45 Cal.

- Joined

- Feb 25, 2004

- Messages

- 882

- Reaction score

- 13

West coast, I am not the brightest bulb in the pack. where is page 2 that you are talking about? I finished a search but had no luck finding it.

Me too Griz....... ::

Russ

Griz; I think at the bottom of the index there are 3 pg's, pg 2 and 3 are in white. Anyway there are the pic's of the one I made (with the wife's help).

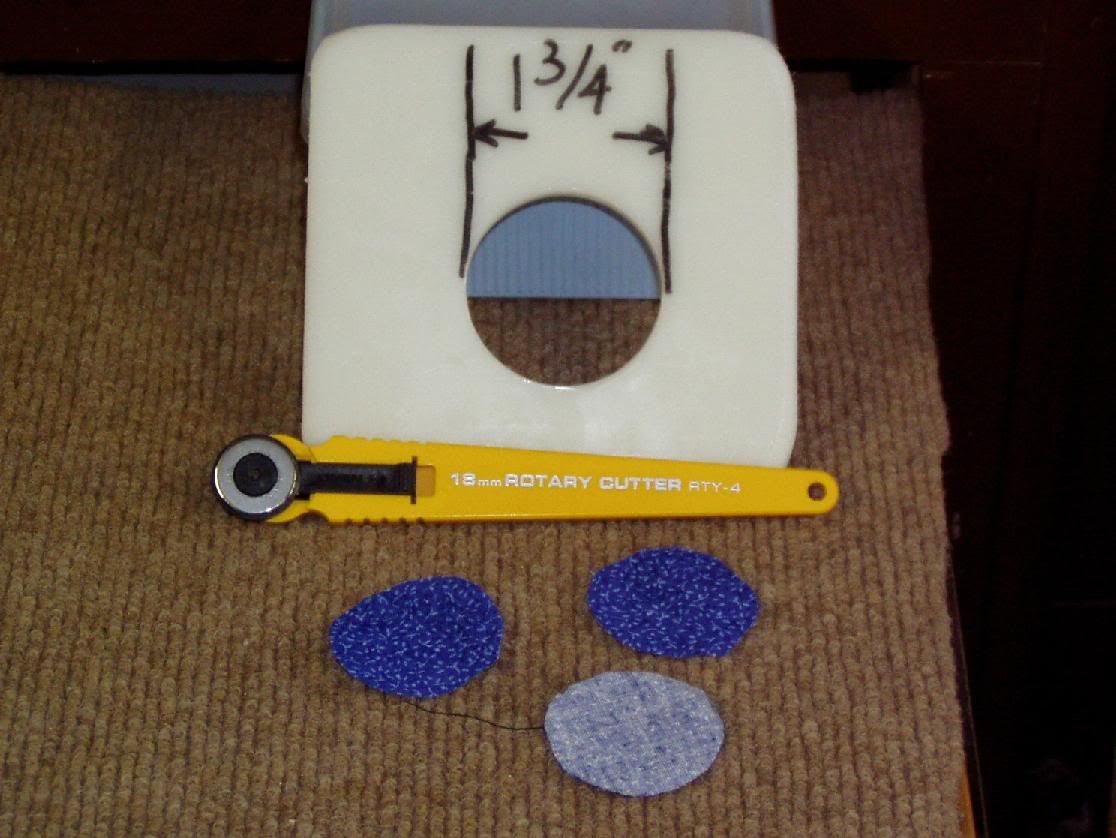

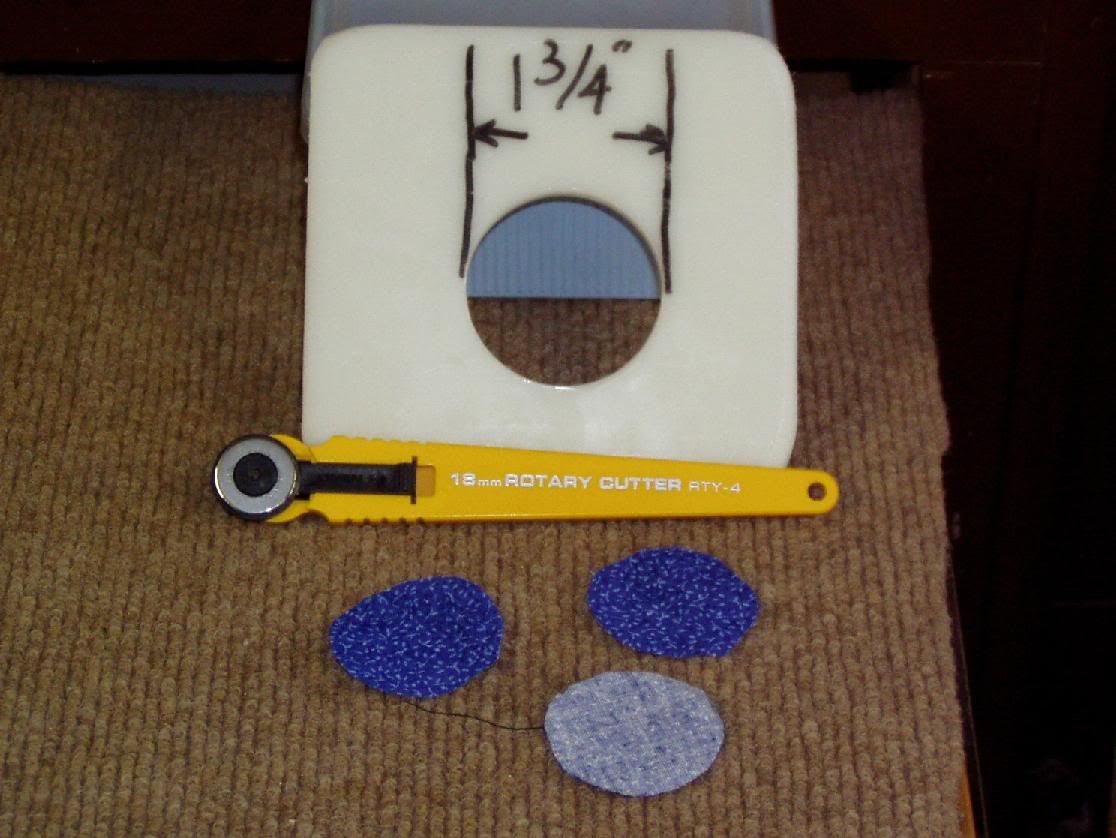

Used the smallest circle cutter they make and a 1/4 by 4x4 inch plastic I got free from a local plastic shop. The black side of the cutter is facing the inside to make it cut better, change the dia of the hole for your cal.

rex (westcoastBPgramps)

bp can be fun

Used the smallest circle cutter they make and a 1/4 by 4x4 inch plastic I got free from a local plastic shop. The black side of the cutter is facing the inside to make it cut better, change the dia of the hole for your cal.

rex (westcoastBPgramps)

bp can be fun