I don't favor use of alcohol for patch lube. It evaporates so rapidly I question whether any remains after a few hours/days/weeks when applied to the cloth. BTW, I cannot find reference to the characteristics of castor oil that make is useful for our purposes. Can somebody help?

I use only alcohol based lubes, because I hate putting water down my barrel when shooting. Water and black powder, don’t like each other. “Keep yer powder dry

Castor oil is an incredibly effective lubricant under extreme heat and pressure. Even if the oil leaves (evaporates), a wax is left behind that is an effective lubricant. Castor oil polymerizes at very high temps and is low ash, according to our race testing. We ran it in outboards at way over 10k rpm.

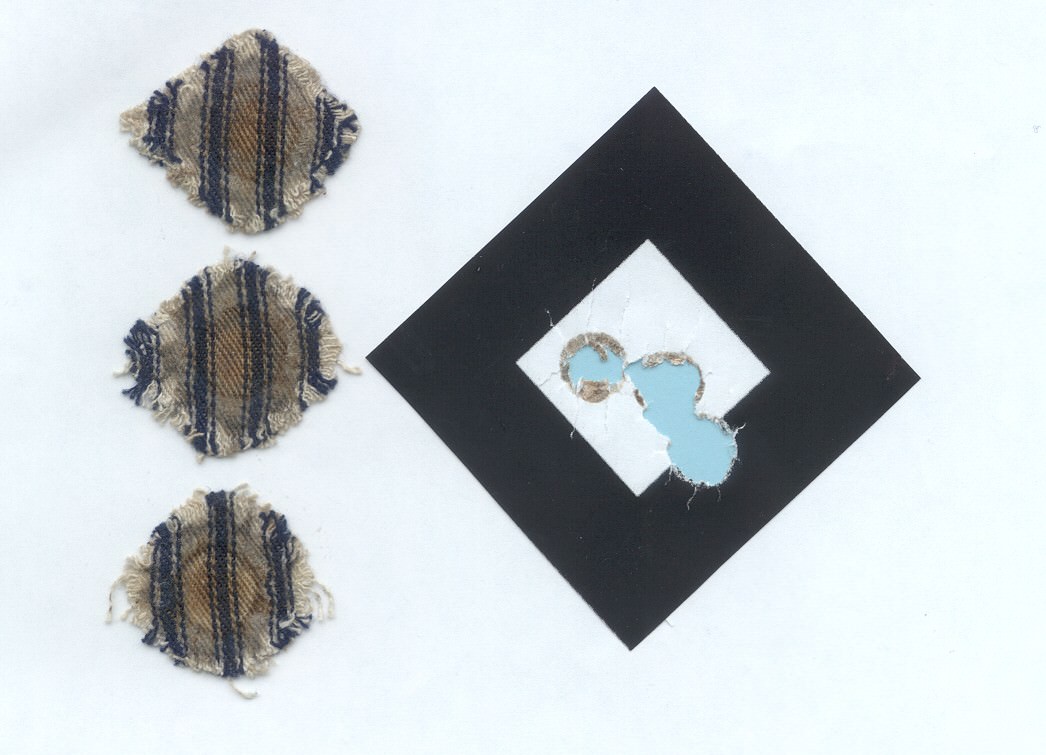

I’ve shot over 130 shots in a small caliber rifle in a day match with never a swabbing. And the last shot went down as easy as the second. I use a very tight combination of land diameter ball & .020 ticking patch. In testing water based lubes, swabbing and not, in my scoped test barrel, this combination provided the most consistent accuracy and velocity. Did testing on some of my others as well up to 50 cal. Same result.