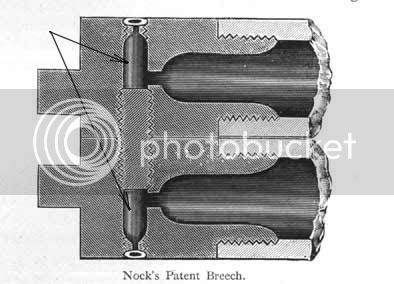

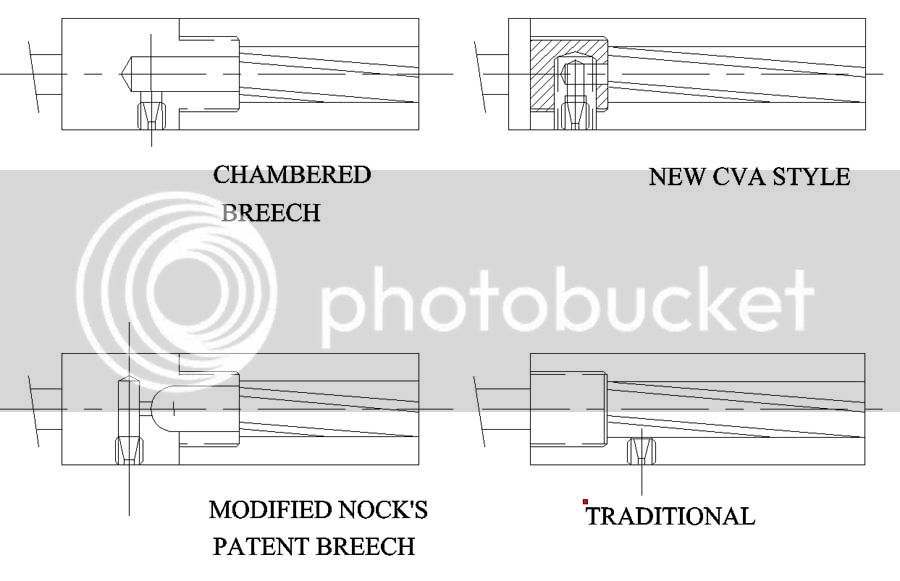

It is true that your GPR has a reduced diameter breech area. While a brush can be used to clean the breech, a little bit of care can keep the fouling from blocking the breech.

If you wipe between shots, use a damp patch and don't run the patch all the way to the patent breech. Occasionally with the damp patch at the breech, fire a cap to clear fouling from the flash chamber. That damp patch will pull all sorts of fouling flakes.

You have a hooked breech. It is simple to pull the wedges to remove the barrel during cleaning. Remove the nipple and with the breech in a bucket of warm water, the flushing action of the cleaning will clean all the fouling from the breech. I like to use WD40 to displace water as I dry the bore. Before putting the gun away, I use a good rust inhibiting lube and I store the rifle with the muzzle down allowing the oils to drain away from the breech. Before your trip to the range, wipe the bore with an alcohol dampened patch to remove the remaining oil.