old ugly

40 Cal.

good morning. i have a question re butt plate attachment.

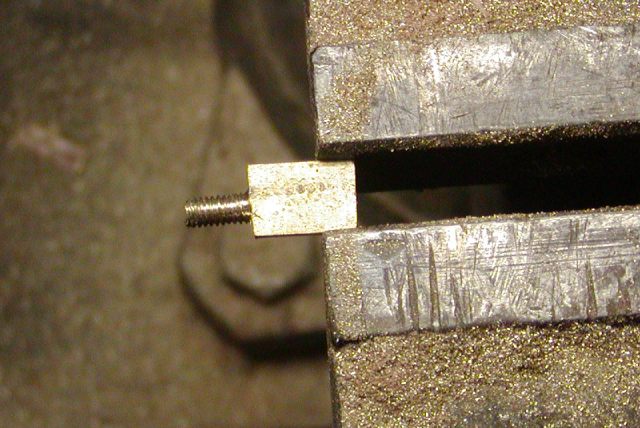

i have a TOW fowler style butt plate, iron, the TOW plate does not have the lug on the tang that secures the front of the return to the stock.

i don't really want to use the MIG to weld one on, but it may be the only way. I don't want a visible screw in the return.

Would this sort of thing have been attached by,

a mortised through the hardware and then riveted over to hold it ? this will be visible.

or

would it have been soldered?

or

maybe by mortise and then solder ?

what have you done?

thanks

ou

tom

i have a TOW fowler style butt plate, iron, the TOW plate does not have the lug on the tang that secures the front of the return to the stock.

i don't really want to use the MIG to weld one on, but it may be the only way. I don't want a visible screw in the return.

Would this sort of thing have been attached by,

a mortised through the hardware and then riveted over to hold it ? this will be visible.

or

would it have been soldered?

or

maybe by mortise and then solder ?

what have you done?

thanks

ou

tom