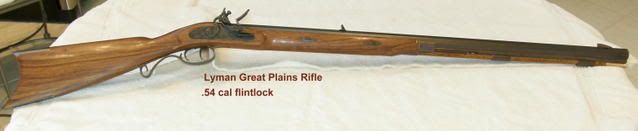

I just received my first muzzleloader for Christmas. It’s a Lyman .54 Cal Great Plains Percussion Rifle (1-60” twist) kit and I have a ton of questions that I’m hoping that some of you folks can help me out with.

As instructed I removed all of the “unfinished” metal parts that were attached to stock. Once I remove all of the casting marks, dents nicks and scratches from them they will be shinny raw steel. I’m wondering what is the best way to finish them? Should I blue or brown them, or leave them alone and possibly lacquer them to keep them rusting. I know that a lot of this is a personal preference, but I like to hear your expert opinions. Also if I Blue or Brown how much buffing is required? So far I’ve removed all of the heavy scratches. I plan upon using this gun to hunt, so I’m not sure how to take it. Truthfully I’m leaning towards Browning just to match the already finished Lock assembly, but I just learned if I buy the “hunter” barrel with a 1-30” twist that it only comes Blued.

Also the Forend Cap is held on with a single pin but it is a tad loose. I was wondering if I could use glue or something else to make it more solid? That may make removing it a later date harder. Is that something I should worry about?

So far I’m fairly impressed with the Lyman’s kit. The only issue I have is I think that they took a little too much wood where the Tang sits. There may be a small gap on the end of the Tang that I fill, but I’m not certain since it still needs some adjusting.

You help is appreciated!

As instructed I removed all of the “unfinished” metal parts that were attached to stock. Once I remove all of the casting marks, dents nicks and scratches from them they will be shinny raw steel. I’m wondering what is the best way to finish them? Should I blue or brown them, or leave them alone and possibly lacquer them to keep them rusting. I know that a lot of this is a personal preference, but I like to hear your expert opinions. Also if I Blue or Brown how much buffing is required? So far I’ve removed all of the heavy scratches. I plan upon using this gun to hunt, so I’m not sure how to take it. Truthfully I’m leaning towards Browning just to match the already finished Lock assembly, but I just learned if I buy the “hunter” barrel with a 1-30” twist that it only comes Blued.

Also the Forend Cap is held on with a single pin but it is a tad loose. I was wondering if I could use glue or something else to make it more solid? That may make removing it a later date harder. Is that something I should worry about?

So far I’m fairly impressed with the Lyman’s kit. The only issue I have is I think that they took a little too much wood where the Tang sits. There may be a small gap on the end of the Tang that I fill, but I’m not certain since it still needs some adjusting.

You help is appreciated!