I know that some of you folks are fairly new to working with wood and you didn't have a chance to take subjects like Wood Shop or even a General Shop class in school. This is for you.

The word "Grain" is used to describe the bundles of fibers that the plant made to form the support structure for it. These bundles are packed close together and they form the board or stock that you will be working with and although they form the wood each grain bundle is separate from the others and can have an influence on how your tools cut it.

A woods grain is seldom parallel with the actual boards edges or with a stocks form. Because of this the grain is usually meeting the surface or the tool at an angle and it is important to recognize this when your working with wood.

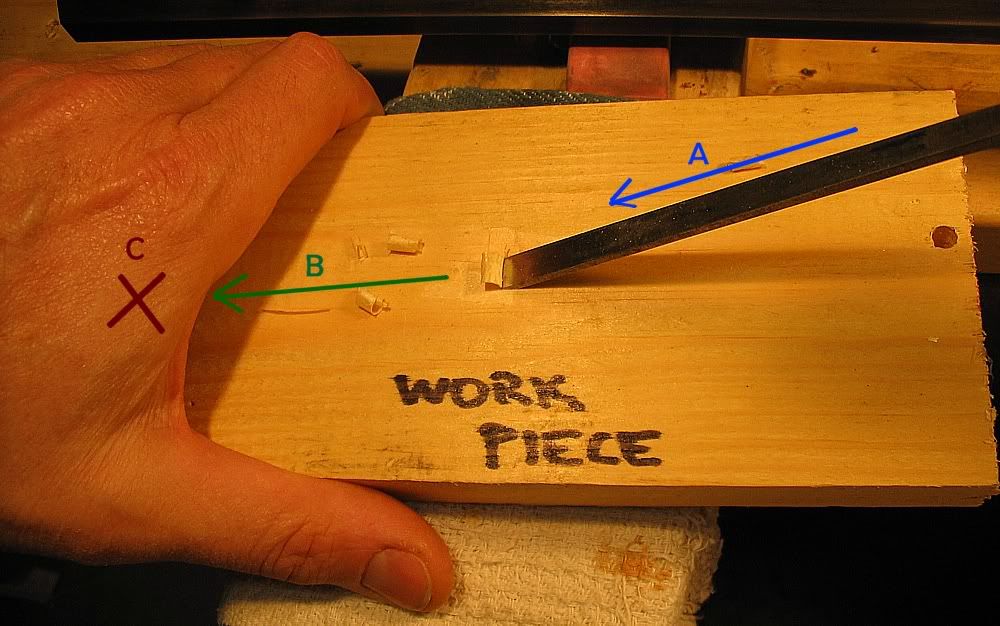

The following is written with a chisel in mind but it applies for any bladed tool that you may be using including scrapers and knives.

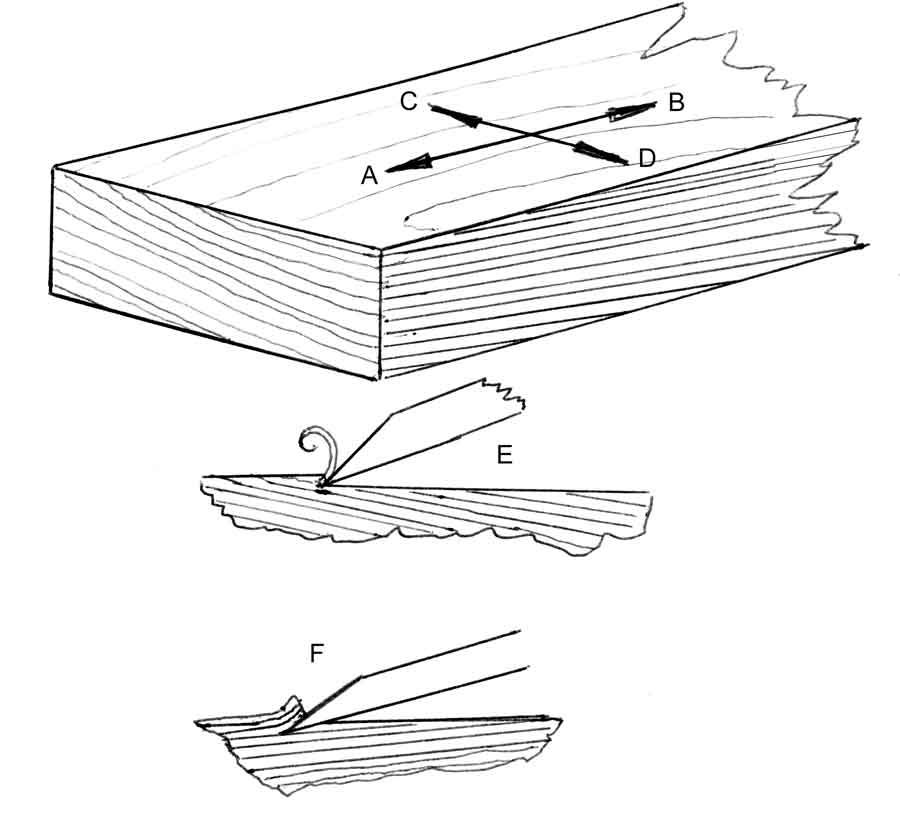

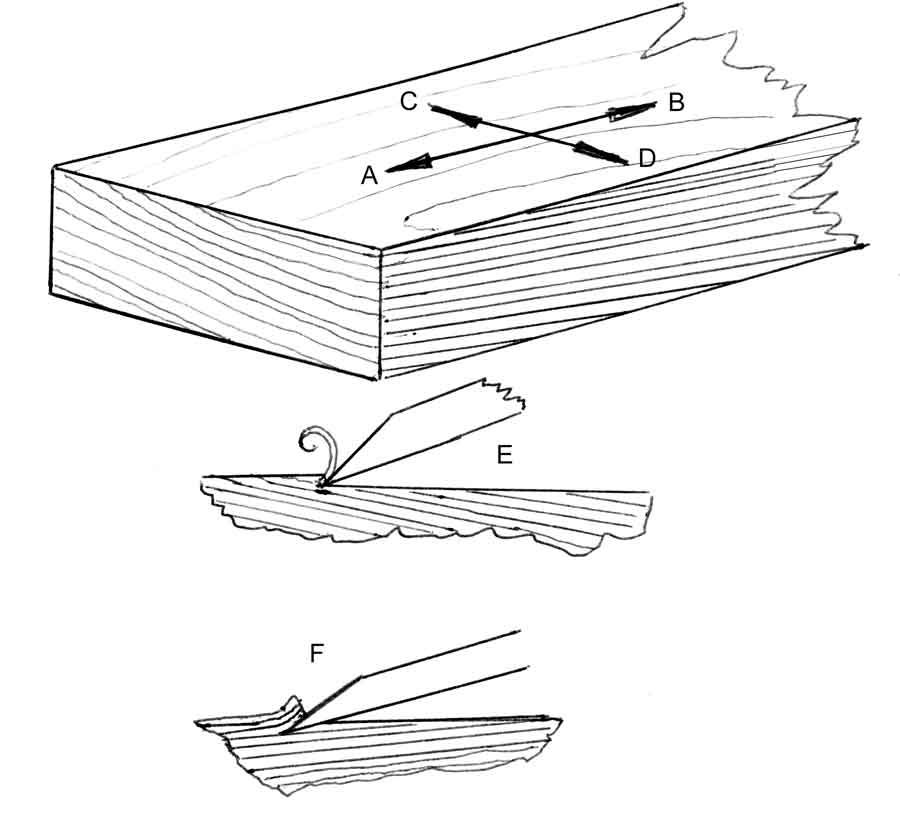

In the drawing below, the long direction of the wood represents the main direction of the woods grain.

You should notice how the grain meets the surface of the board. It is rising from the lower area of the board on the right side and coming out the upper surface towards the left side. In the cross grain direction it is coming from the lower right and moving towards the upper left of the board.

If you are using a chisel to cut into the top surface you have 4 major directions that you can push the chisel, A, B, C and D.

If you push the chisel in the A direction the chisel will smoothly cut into the wood as is shown in E producing a smooth curling chip.

This is called "cutting With the grain". The cut will be smooth and the chisel is easy to control. It will not want to plow into the wood because it is being supported by the fiber between the grains.

If you push the chisel in the B direction the chisel will tend to follow the grain of the wood and it will plow into the board as shown in view F. This is called "cutting AGAINST the grain" and it should be avoided at all costs unless there is absolutely no other way to remove some wood from the board or stock.

There will be times when your only choice is to cut the grain as depicted by C or D.

This is called "Cutting Across the Grain."

Because cutting in this direction tends to slice thru the grain bundles perpendicular to the grain flow the cuts will be clean and the chisel will not want to plow into the wood.

It does tend to leave small bits of fibers sticking out of the surface where the edge of the chisel stops but a bit of sanding or scraping can eliminate these.

So. Now your sitting there looking at your stock and the first question is, "OK Zonie, I see the main direction of the grain and its running the length of the stock. I know I want to chisel it "with the grain" but how the Hell do I figure out which direction is "with the grain"?"

The answer is, "Let the wood tell you."

"Ah?" says you. "Ole Zonie has really flipped out this time. He thinks wood can talk!"

Well, it can't talk by itself but it can "talk" to your tools.

As soon as you start to cut it the wood will either allow the cutting edge to glide smoothly along cutting with the grain or the cutting edge will want to plow into the surface. If it wants to plow in, your cutting against the grain.

As soon as you feel the cutting edge start to plow into the wood, STOP. Reverse the direction of the cut and then proceed if it is possible.

If it is not possible you can either change the direction so the tool is cutting across the grain or bite the bullet and tell yourself, "There is no other way so be VERY careful."

If you MUST cut against the grain reduce the angle of the tool to the work so it is just barely cutting into the surface while keeping it from skimming across the wood without cutting. This is a fine line to walk and it takes some practice.

This is especially important if you are working with the "curly" woods because they will grab the cutting edge worse than normal wood. Curly wood also tends to "chip out" when your cutting against the grain so be very careful.

To sum up, wood has grain. The subtile angles that it meets the surface at cannot always be seen but your tool can tell you if your cutting in the best direction.

The grain can be used to help you or you can fight it.

Going with the grain is always best.

I know you folks already know this but keep your chisels SHARP. They should be as sharp as a razor blade. If they are as sharp as they should be light to medium hand pressure is all that is required to cut wood and by keeping your hand pressure light you will be able to control exactly where and how deep the tool is cutting.

Have Fun.

As usual, I forgot to talk about another common situation when working with a chisel.

That is, cutting across the "End Grain" which is another way of saying cutting across the grain bundles where the board ends.

For a single edged tool like a chisel this can be a challenge, even if the chisel is kept razor sharp.

Wood grains are pretty tough little critters and they don't like being whacked off. In fact, working together they can rapidly dull your razor sharp chisel edge.

There will be times when their is no other choice but to cut directly across the grain, like when you are finishing the end of the barrel channel for the barrel to rest against.

The first thing to recognize is that when the grain bundles are cut they will use their grip on the adjacent uncut wood fibers to stay where they are. The only way to remove them is to break their bond or grip on the adjacent fibers.

Because of this, keep the depth of your cut very shallow. Do not try to remove 1/8" of wood at one time by whacking the chisel with a hammer in an attempt to drive it down into the wood. Doing this will really dull up your chisel and it usually breaks the grain bundles away from their neighboring grains resulting in weakening the wood.

Few people would try to cut thru the grain of a piece of meat by pushing their knife directly down thru it. Rather, they slice the meat by moving the knifes edge back and forth while applying the downward pressure.

Cutting thru end grain of wood works exactly the same way. If you can slide the chisel back and forth like a knife while applying downward pressure the main resistance from the wood will be restricted to the woods resistance to breaking away and if the cut is shallow removing the wood will not be difficult.

This idea kinda eliminates the possibility of doing what many new builders want to do.

"What is that?" you ask?

They always want to use a 1 inch wide chisel to clean up the end of the barrel channel for a 1 inch barrel based on the idea that they can do it, "all in just one cut. :grin: "

Actually IMO for gun building a chisel wider than 1/2 inch is pretty useless.

A 1/2" wide chisel will allow it to be moved sideways to slice thru end grain and because it is narrow it is easier to control.

A 3/8" or 1/4" wide chisel is even easier to control so don't say ol' Zonie said you need to run out and buy a 1/2" chisel.

Also don't forget that when your cutting wood to get a good fit between the wood and a metal part it is much better to shave off just a hair of wood and check the fit many times than to try to remove a lot of wood with one cut.

Now you can go Have Fun.

The word "Grain" is used to describe the bundles of fibers that the plant made to form the support structure for it. These bundles are packed close together and they form the board or stock that you will be working with and although they form the wood each grain bundle is separate from the others and can have an influence on how your tools cut it.

A woods grain is seldom parallel with the actual boards edges or with a stocks form. Because of this the grain is usually meeting the surface or the tool at an angle and it is important to recognize this when your working with wood.

The following is written with a chisel in mind but it applies for any bladed tool that you may be using including scrapers and knives.

In the drawing below, the long direction of the wood represents the main direction of the woods grain.

You should notice how the grain meets the surface of the board. It is rising from the lower area of the board on the right side and coming out the upper surface towards the left side. In the cross grain direction it is coming from the lower right and moving towards the upper left of the board.

If you are using a chisel to cut into the top surface you have 4 major directions that you can push the chisel, A, B, C and D.

If you push the chisel in the A direction the chisel will smoothly cut into the wood as is shown in E producing a smooth curling chip.

This is called "cutting With the grain". The cut will be smooth and the chisel is easy to control. It will not want to plow into the wood because it is being supported by the fiber between the grains.

If you push the chisel in the B direction the chisel will tend to follow the grain of the wood and it will plow into the board as shown in view F. This is called "cutting AGAINST the grain" and it should be avoided at all costs unless there is absolutely no other way to remove some wood from the board or stock.

There will be times when your only choice is to cut the grain as depicted by C or D.

This is called "Cutting Across the Grain."

Because cutting in this direction tends to slice thru the grain bundles perpendicular to the grain flow the cuts will be clean and the chisel will not want to plow into the wood.

It does tend to leave small bits of fibers sticking out of the surface where the edge of the chisel stops but a bit of sanding or scraping can eliminate these.

So. Now your sitting there looking at your stock and the first question is, "OK Zonie, I see the main direction of the grain and its running the length of the stock. I know I want to chisel it "with the grain" but how the Hell do I figure out which direction is "with the grain"?"

The answer is, "Let the wood tell you."

"Ah?" says you. "Ole Zonie has really flipped out this time. He thinks wood can talk!"

Well, it can't talk by itself but it can "talk" to your tools.

As soon as you start to cut it the wood will either allow the cutting edge to glide smoothly along cutting with the grain or the cutting edge will want to plow into the surface. If it wants to plow in, your cutting against the grain.

As soon as you feel the cutting edge start to plow into the wood, STOP. Reverse the direction of the cut and then proceed if it is possible.

If it is not possible you can either change the direction so the tool is cutting across the grain or bite the bullet and tell yourself, "There is no other way so be VERY careful."

If you MUST cut against the grain reduce the angle of the tool to the work so it is just barely cutting into the surface while keeping it from skimming across the wood without cutting. This is a fine line to walk and it takes some practice.

This is especially important if you are working with the "curly" woods because they will grab the cutting edge worse than normal wood. Curly wood also tends to "chip out" when your cutting against the grain so be very careful.

To sum up, wood has grain. The subtile angles that it meets the surface at cannot always be seen but your tool can tell you if your cutting in the best direction.

The grain can be used to help you or you can fight it.

Going with the grain is always best.

I know you folks already know this but keep your chisels SHARP. They should be as sharp as a razor blade. If they are as sharp as they should be light to medium hand pressure is all that is required to cut wood and by keeping your hand pressure light you will be able to control exactly where and how deep the tool is cutting.

Have Fun.

As usual, I forgot to talk about another common situation when working with a chisel.

That is, cutting across the "End Grain" which is another way of saying cutting across the grain bundles where the board ends.

For a single edged tool like a chisel this can be a challenge, even if the chisel is kept razor sharp.

Wood grains are pretty tough little critters and they don't like being whacked off. In fact, working together they can rapidly dull your razor sharp chisel edge.

There will be times when their is no other choice but to cut directly across the grain, like when you are finishing the end of the barrel channel for the barrel to rest against.

The first thing to recognize is that when the grain bundles are cut they will use their grip on the adjacent uncut wood fibers to stay where they are. The only way to remove them is to break their bond or grip on the adjacent fibers.

Because of this, keep the depth of your cut very shallow. Do not try to remove 1/8" of wood at one time by whacking the chisel with a hammer in an attempt to drive it down into the wood. Doing this will really dull up your chisel and it usually breaks the grain bundles away from their neighboring grains resulting in weakening the wood.

Few people would try to cut thru the grain of a piece of meat by pushing their knife directly down thru it. Rather, they slice the meat by moving the knifes edge back and forth while applying the downward pressure.

Cutting thru end grain of wood works exactly the same way. If you can slide the chisel back and forth like a knife while applying downward pressure the main resistance from the wood will be restricted to the woods resistance to breaking away and if the cut is shallow removing the wood will not be difficult.

This idea kinda eliminates the possibility of doing what many new builders want to do.

"What is that?" you ask?

They always want to use a 1 inch wide chisel to clean up the end of the barrel channel for a 1 inch barrel based on the idea that they can do it, "all in just one cut. :grin: "

Actually IMO for gun building a chisel wider than 1/2 inch is pretty useless.

A 1/2" wide chisel will allow it to be moved sideways to slice thru end grain and because it is narrow it is easier to control.

A 3/8" or 1/4" wide chisel is even easier to control so don't say ol' Zonie said you need to run out and buy a 1/2" chisel.

Also don't forget that when your cutting wood to get a good fit between the wood and a metal part it is much better to shave off just a hair of wood and check the fit many times than to try to remove a lot of wood with one cut.

Now you can go Have Fun.