- Joined

- Nov 26, 2005

- Messages

- 5,020

- Reaction score

- 9,978

Hi,

There is a current thread asking about what to do to refurbish a Pedersoli Brown Bess musket to make the gun more historically correct. After contributing to that discussion, I thought I would add this separate thread that describes how I go about historically upgrading those guns. I will document a refurbishing job that I am currently doing and I will post photos and text as I go. First and foremost, you have to know the historical details for the different musket patterns. The Pedersoli Bess is essentially a 1769 short land pattern. There are 2 major issues that are very difficult or impossible to correct on the Perdersolis. First, the lock is incorrectly marked “Grice 1762”. By the time the pattern 1769 was issued, musket locks were no longer engraved with the lock contractor’s name and the date of lock manufacture (not the date issued or date installed on a musket by ordnance). If you have an original short land pattern Bess with a lock marked “Grice” or some other contractor, you likely have a 1759 Marine and militia musket. Pattern 1769s that made it to America should be engraved “Dublin Castle” or “Tower” with no date. Second, the buttplate is 1/4”-3/8” too small in height. That does not sound like much but it makes a big difference in the lower profile of the buttstock making the butt stock too small. That is why Pedersoli Besses always look like the butt is disproportionately small relative to the lock area compared with original Brown Besses. These are items that you normally have to live with. What you do not have to live with is the fact that Pedersoli and all other mass reproduced Besses are like ¾ completed kits with respect to the stock and fittings. This is where I will begin and eventually I will work on the lock, barrel, and swivels.

Below, I have a Pedersoli Bess made during the 1970s. It is definitely one of the better guns historically because they did a better job shaping the lock area and reducing wood along the forestock. This is a re-enactors gun and it clearly was not well cared for. I will clean up all the metal parts and barrel. A previous owner obviously believed Brown Bess barrels should be browned. That will be removed when I derust and clean up the barrel. So my first job is to disassemble the gun completely and correct the inlets. This particular gun came apart OK but the tang screw, flintcock tumbler screw, and screw holding on the wrist plate were all badly corroded. I used penetrating oil where I could and then used an adjustable wrench on the shafts of my good fitting screw drivers to give me extra leverage. That did the trick because with one hand you can push down the turnscrew so it does not slip and with the other you turn the wrench. Be careful when removing the barrel, ramrod thimble, trigger guard, and trigger pins. My rule is that they all are tapped out from the lock side and reinserted from the sideplate side. That is consistent with other British sporting guns at the time. The exceptions are the trigger pin and the front trigger guard pin. Those I tap from the side plate side so they exit within the lock mortice. The pins were usually filed flush with the wood and may have a burr that can chip the stock as they are removed. The rest of the gun should come apart easily. When removing the lock, back out the bolts all the way and then tap them to push the lock out. It is wise to place the lock at halfcock when removing it for the first time to prevent the mainspring from catching in the mortice should it be close to the edge of the lockplate when at rest.

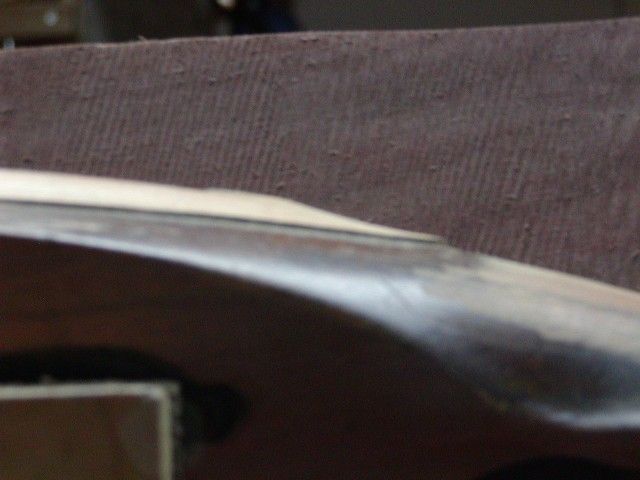

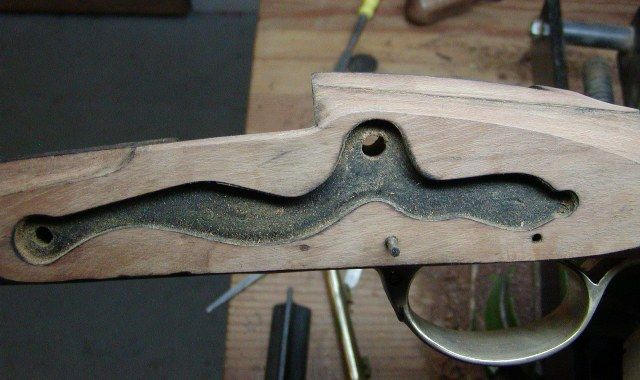

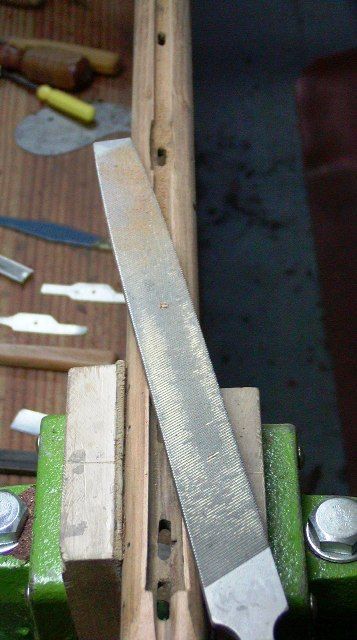

I’ll start by reshaping the barrel tang apron, the lock panels, and fixing the inletting of the hardware. Note in the photos below, that the trigger guard, trigger plate, lock, and rear ramrod thimble are all set in the wood too deeply. Actually, they are fine with respect to their correct positions in the stock, it is just that the stock has too much wood left on. The barrel tang apron sits up too high and does not have the correct concave surface. I draw a border around the tang that will remain untouched and then start filing and scraping to lower the apron and give it a concave surface.

I'll add more soon.

dave

There is a current thread asking about what to do to refurbish a Pedersoli Brown Bess musket to make the gun more historically correct. After contributing to that discussion, I thought I would add this separate thread that describes how I go about historically upgrading those guns. I will document a refurbishing job that I am currently doing and I will post photos and text as I go. First and foremost, you have to know the historical details for the different musket patterns. The Pedersoli Bess is essentially a 1769 short land pattern. There are 2 major issues that are very difficult or impossible to correct on the Perdersolis. First, the lock is incorrectly marked “Grice 1762”. By the time the pattern 1769 was issued, musket locks were no longer engraved with the lock contractor’s name and the date of lock manufacture (not the date issued or date installed on a musket by ordnance). If you have an original short land pattern Bess with a lock marked “Grice” or some other contractor, you likely have a 1759 Marine and militia musket. Pattern 1769s that made it to America should be engraved “Dublin Castle” or “Tower” with no date. Second, the buttplate is 1/4”-3/8” too small in height. That does not sound like much but it makes a big difference in the lower profile of the buttstock making the butt stock too small. That is why Pedersoli Besses always look like the butt is disproportionately small relative to the lock area compared with original Brown Besses. These are items that you normally have to live with. What you do not have to live with is the fact that Pedersoli and all other mass reproduced Besses are like ¾ completed kits with respect to the stock and fittings. This is where I will begin and eventually I will work on the lock, barrel, and swivels.

Below, I have a Pedersoli Bess made during the 1970s. It is definitely one of the better guns historically because they did a better job shaping the lock area and reducing wood along the forestock. This is a re-enactors gun and it clearly was not well cared for. I will clean up all the metal parts and barrel. A previous owner obviously believed Brown Bess barrels should be browned. That will be removed when I derust and clean up the barrel. So my first job is to disassemble the gun completely and correct the inlets. This particular gun came apart OK but the tang screw, flintcock tumbler screw, and screw holding on the wrist plate were all badly corroded. I used penetrating oil where I could and then used an adjustable wrench on the shafts of my good fitting screw drivers to give me extra leverage. That did the trick because with one hand you can push down the turnscrew so it does not slip and with the other you turn the wrench. Be careful when removing the barrel, ramrod thimble, trigger guard, and trigger pins. My rule is that they all are tapped out from the lock side and reinserted from the sideplate side. That is consistent with other British sporting guns at the time. The exceptions are the trigger pin and the front trigger guard pin. Those I tap from the side plate side so they exit within the lock mortice. The pins were usually filed flush with the wood and may have a burr that can chip the stock as they are removed. The rest of the gun should come apart easily. When removing the lock, back out the bolts all the way and then tap them to push the lock out. It is wise to place the lock at halfcock when removing it for the first time to prevent the mainspring from catching in the mortice should it be close to the edge of the lockplate when at rest.

I’ll start by reshaping the barrel tang apron, the lock panels, and fixing the inletting of the hardware. Note in the photos below, that the trigger guard, trigger plate, lock, and rear ramrod thimble are all set in the wood too deeply. Actually, they are fine with respect to their correct positions in the stock, it is just that the stock has too much wood left on. The barrel tang apron sits up too high and does not have the correct concave surface. I draw a border around the tang that will remain untouched and then start filing and scraping to lower the apron and give it a concave surface.

I'll add more soon.

dave