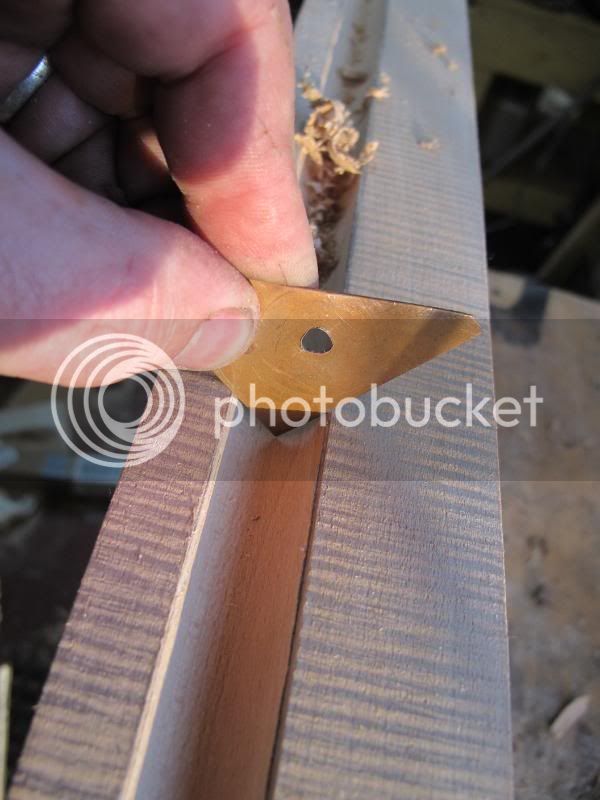

I will start out with Barrel layout.. The only measurements I get are the breech height/width and then at the muzzle.

Basic layout lines to start out from.

Having removed the waste wood I have found where I want to have the barrel centered. Allowing enough room for the lock panels and cast off.

I am going to be using a router to help remove a bit of wood. If you do not have a router my method will still work.

My outside vice with the router.. if its raining out I do the inlet all with hand tools if I can't wait.

My first cuts are with a 3/4" square bit..

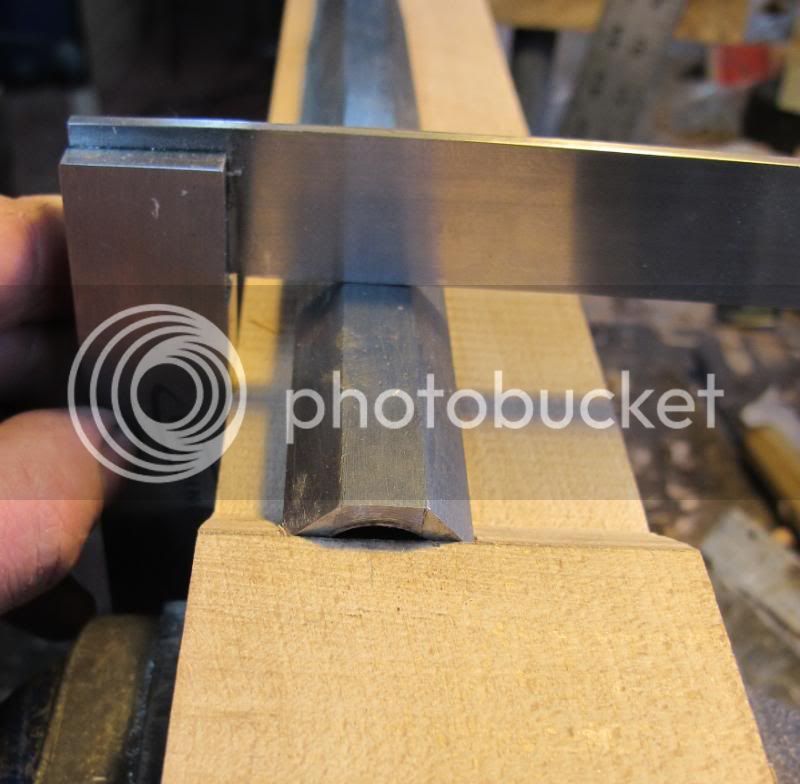

Depth gauge showing I took it to my center mark of the barrel.

Basic layout lines to start out from.

Having removed the waste wood I have found where I want to have the barrel centered. Allowing enough room for the lock panels and cast off.

I am going to be using a router to help remove a bit of wood. If you do not have a router my method will still work.

My outside vice with the router.. if its raining out I do the inlet all with hand tools if I can't wait.

My first cuts are with a 3/4" square bit..

Depth gauge showing I took it to my center mark of the barrel.