The extension on the top of the butt plate should be parallel with the comb of the stock at the rear.

When installed it will be flush with the top of the comb and look like a continuation of the wood surface.

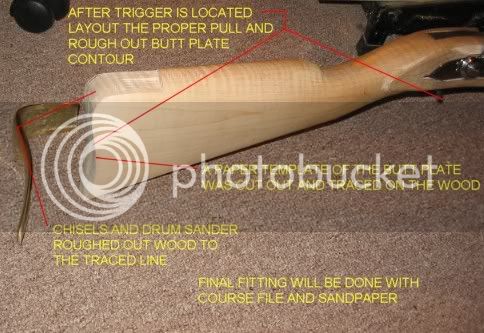

The length of pull, measured from the shooting trigger should be to the area half way between the heel and the toe. With deeply curved butt plates this is usually the "lowest" area.

I usually make a paper pattern of the surfaces that will end up against the wood and use this as a guide for drawing the shape on the stock.

It usually takes several "drawings" before I'm sure both sides of the stock have marking that is right.

After getting the lines drawn I rough saw the shape to about 1/4" from the lines.

I also cheat a bit by using 2 inch diameter expanding drums with replaceable sandpaper cylinders in my electric drill to remove most of the material down to the drawn lines.

Once this is done I will locate the butt plate against the wood and draw the forward location of the 'return'. Once drawn I cut on this line down

almost to the full depth that will be required to position the top of return flush with the comb. The final depth and location will be made with chisels.

After the cuts are at this stage I go to my double cut files and occasionally the 1/2" rubber expanding sanding drum in my Dremals flexable drive.

Check out this link for a bit more on installing a butt plate.

http://www.muzzleloadingforum.com/...d/15625/post/15625/hl/"bgunbut1"/fromsearch/1/