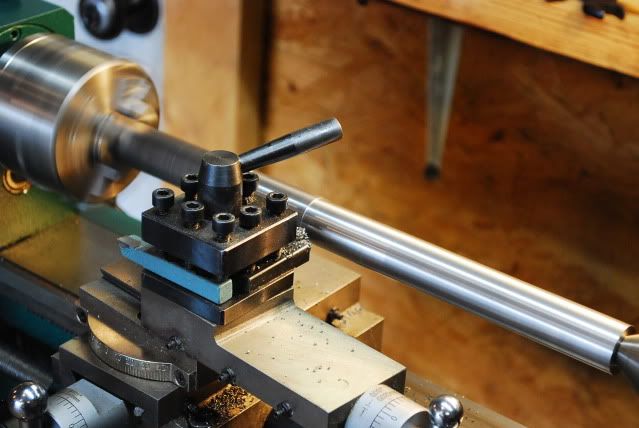

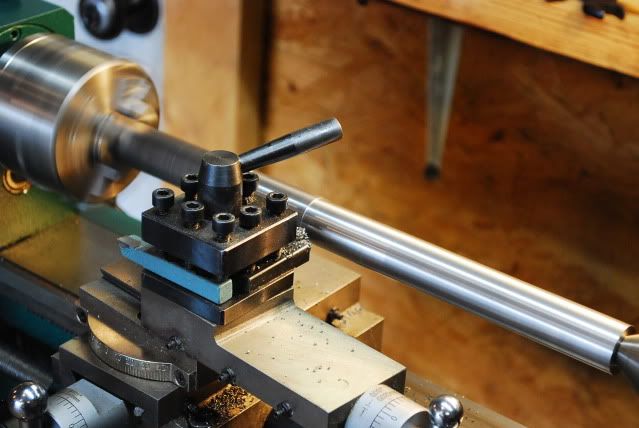

Well got my barrel and stock in yesterday and i decided i could not go with a straight barrel.so i put it in the lathe and made it about a 2\3 round to octagonal. It should really help with the weight and it is swamped, but in the done picture it is hard to tell. I am not buying nothing else for this gun but a lock and maybe a trigger guard.I will need to draw file the back part to get the scratches out, but i think i am going to just polish it and let it patina over or blue and knock it back with steel wool. But i have a long way to go before i worry about that. the stock is supposed to be a ++p but i dont know? mike miller is sending me a pattern for this gun. very nice of him... i will take better pictures later.