Hi all! A friend of mine is starting a project of refinishing his dads percussion pendersoli double-barrel smoothbore. He tried to remove both nipples and one came out easily. The other was so corroded it snapped. He was able to drill it out and asked me to re-tap it.

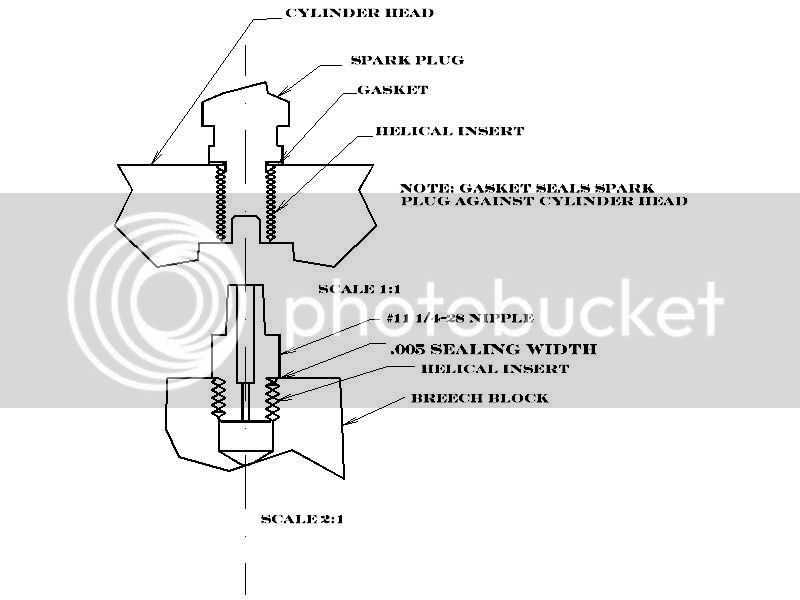

I was able to re-tap it (1/4-28), but when he drilled out the nipple, he opened the top too wide and the threads will not catch.

I feel like I have two choices and the first may not even be a option. I don't know:

1. Find a nipple that has about twice the ammount of threads. (If they make these it may work because the threads go pretty far down).

2. Open it up to the next common size? (maybe 5/16-24?)

If I go that route, should I do them both or leave them different. He does not plan to shoot single projectile. His plan is to shoot shot for small game type shooting.

Thanks in advance for any input!

I was able to re-tap it (1/4-28), but when he drilled out the nipple, he opened the top too wide and the threads will not catch.

I feel like I have two choices and the first may not even be a option. I don't know:

1. Find a nipple that has about twice the ammount of threads. (If they make these it may work because the threads go pretty far down).

2. Open it up to the next common size? (maybe 5/16-24?)

If I go that route, should I do them both or leave them different. He does not plan to shoot single projectile. His plan is to shoot shot for small game type shooting.

Thanks in advance for any input!