I'm inletting the lock in my "Leman - sort of" project, and I've made a little mistake.

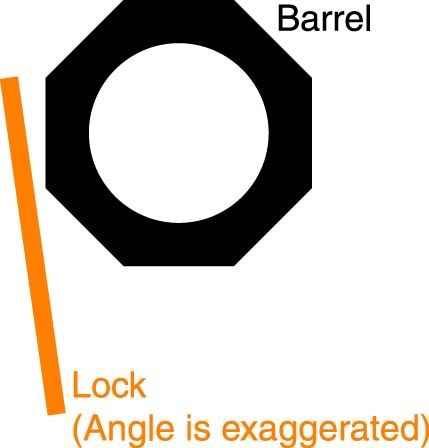

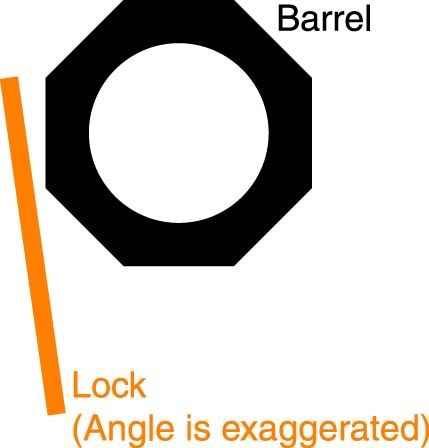

I've inletted the lock opening too deep on the bottom of the lockplate. When the plate hits the bottom on the inletted area, it's not perpendicular to the barrel face. The top is fine, because it rests against the barrel.

How can I raise the area at the bottom of the inletted area? I only need to kick it out about 1/32" or so.

Thanks in advance,

WindLaker

I've inletted the lock opening too deep on the bottom of the lockplate. When the plate hits the bottom on the inletted area, it's not perpendicular to the barrel face. The top is fine, because it rests against the barrel.

How can I raise the area at the bottom of the inletted area? I only need to kick it out about 1/32" or so.

Thanks in advance,

WindLaker

unfortunate days where things just don't go as they are supposed to go..... :shake:

unfortunate days where things just don't go as they are supposed to go..... :shake: