I have a Howdah Pistol with overcleaned barrels. Had some surface rust and dunked it in my electrolysis barrel. I want to be able to see the Damascus patterns but get rid of the "over-sanitized" Look. What chemicals do I need and best way of applying same?

-

This community needs YOUR help today. We rely 100% on Supporting Memberships to fund our efforts. With the ever increasing fees of everything, we need help. We need more Supporting Members, today. Please invest back into this community. I will ship a few decals too in addition to all the account perks you get.

Sign up here: https://www.muzzleloadingforum.com/account/upgrades -

Friends, our 2nd Amendment rights are always under attack and the NRA has been a constant for decades in helping fight that fight.

We have partnered with the NRA to offer you a discount on membership and Muzzleloading Forum gets a small percentage too of each membership, so you are supporting both the NRA and us.

Use this link to sign up please; https://membership.nra.org/recruiters/join/XR045103

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to work with staining Damascus?

- Thread starter Marplot

- Start date

Help Support Muzzleloading Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Most knife makers use a combination of muriatic acid and hydrogen peroxide to etch Damascus steel.

A simple acid treatment should bring out the Damascus pattern. Then neutralize and wax. I believe using H2O2, mustard or other chemicals would add effects that are not part of the true pattern that is in the barrel. BTW, interesting pistol there.

Sam squanch

62 Cal.

- Joined

- Oct 9, 2019

- Messages

- 2,749

- Reaction score

- 3,769

If you use any acid, please wear the proper protective gear. And have a way to neutralize the acid when you get the finish you want.

Scota@4570

54 Cal.

- Joined

- Nov 25, 2019

- Messages

- 1,733

- Reaction score

- 2,102

Larry Akers

40 Cal.

- Joined

- Jun 6, 2016

- Messages

- 414

- Reaction score

- 193

An excellent in-depth treatise on this subject can be found in The Double Gun Journal, Vol.8 nos. 2 and 3. Short version, decide if you want a brown or black color. If brown, coat the barrel (after degreasing) with a slow rust product ( ie LMF) allow to rust then card ALL the rust off then plug the barrel and immerse in a 15% dilution of commercial ferric chloride for 10-15 seconds. Rinse immediately and card again. Repeat until color is satisfactory. If desired color is black, apply browning solution, allow to rust, boil in distilled water 15-20 min. then card. Immerse in the ferric chloride as above and repeat until desired color is achieved.

Just ordered ferric chloride from Amazon. Thanks, especially I need to plug the barrel(s)

- Joined

- Nov 26, 2005

- Messages

- 5,021

- Reaction score

- 9,981

Hi,

The formulas used to brown stub and Damascus barrels are less important than how they are applied. In general, you want any acid solution to be dilute even if you buy it commercially, dilute it with something like alcohol. To do a first rate job, the barrel should be very well polished. Degrease the barrel thoroughly and wear rubber gloves when handling the barrel. Acetone works well for that. Apply a thin coat of browning solution on the barrel with a swab but just swab once and evenly. Don't rub back and forth and put on a heavy coat. Let the barrel sit until it develops a thin coat of rust but no more than 4 hours unless you are in a very dry location. It is best to have a soft stainless steel buffing wheel such as those made by Grobet. These are very soft, more mop like than bristle like. Fine Scotch Bright pads will work in a pinch. If using the wheel, turn at very slow rpms so no heat develops and card the barrel (remove the loose rust) with the wheel. Then apply the next coat of dilute browning and repeat. However, just let the barrel rust for 2 hours or so and card again. You may have to repeat the cycles 20-30 times to create the color you desire but be patient. The goal is very fine grained rusting that leaves a smooth shiny translucent surface behind rather than a coarse, mat surface. After the final carding you can do several things. Wash the barrel in water and dry it and then simply heat the barrel a little and apply beeswax and buff it to a high polish. You can also wash the barrel with scalding (NOT BOILING) water, dry it and let it after rust a little, then a final carding. That will bring out deeper red colors and then heat and buff with beeswax. Finally, you can wash or sit the barrel in boiling water, remove, let dry and then gently rub it with fine Scotch Bright or 0000 steel wool, heat and buff it with beeswax. The boiling will turn the browning to a blue-black color.

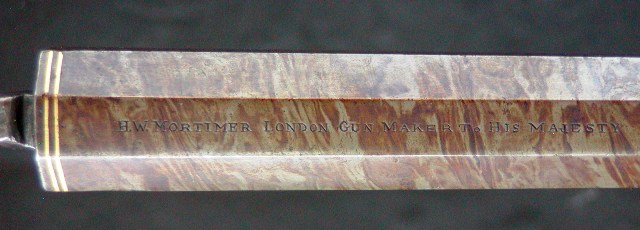

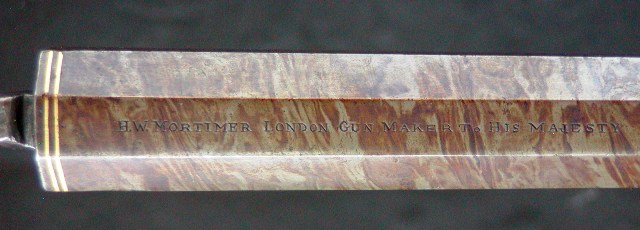

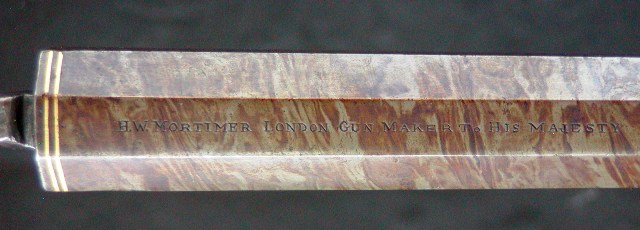

Here is a barrel done by Pete Mazur, one of the best gun finishers around, that shows the fine, smooth, translucent finish found on high quality English guns.

dave

The formulas used to brown stub and Damascus barrels are less important than how they are applied. In general, you want any acid solution to be dilute even if you buy it commercially, dilute it with something like alcohol. To do a first rate job, the barrel should be very well polished. Degrease the barrel thoroughly and wear rubber gloves when handling the barrel. Acetone works well for that. Apply a thin coat of browning solution on the barrel with a swab but just swab once and evenly. Don't rub back and forth and put on a heavy coat. Let the barrel sit until it develops a thin coat of rust but no more than 4 hours unless you are in a very dry location. It is best to have a soft stainless steel buffing wheel such as those made by Grobet. These are very soft, more mop like than bristle like. Fine Scotch Bright pads will work in a pinch. If using the wheel, turn at very slow rpms so no heat develops and card the barrel (remove the loose rust) with the wheel. Then apply the next coat of dilute browning and repeat. However, just let the barrel rust for 2 hours or so and card again. You may have to repeat the cycles 20-30 times to create the color you desire but be patient. The goal is very fine grained rusting that leaves a smooth shiny translucent surface behind rather than a coarse, mat surface. After the final carding you can do several things. Wash the barrel in water and dry it and then simply heat the barrel a little and apply beeswax and buff it to a high polish. You can also wash the barrel with scalding (NOT BOILING) water, dry it and let it after rust a little, then a final carding. That will bring out deeper red colors and then heat and buff with beeswax. Finally, you can wash or sit the barrel in boiling water, remove, let dry and then gently rub it with fine Scotch Bright or 0000 steel wool, heat and buff it with beeswax. The boiling will turn the browning to a blue-black color.

Here is a barrel done by Pete Mazur, one of the best gun finishers around, that shows the fine, smooth, translucent finish found on high quality English guns.

dave

Awesome and worth the effort!

Hi,

The formulas used to brown stub and Damascus barrels are less important than how they are applied. In general, you want any acid solution to be dilute even if you buy it commercially, dilute it with something like alcohol. To do a first rate job, the barrel should be very well polished. Degrease the barrel thoroughly and wear rubber gloves when handling the barrel. Acetone works well for that. Apply a thin coat of browning solution on the barrel with a swab but just swab once and evenly. Don't rub back and forth and put on a heavy coat. Let the barrel sit until it develops a thin coat of rust but no more than 4 hours unless you are in a very dry location. It is best to have a soft stainless steel buffing wheel such as those made by Grobet. These are very soft, more mop like than bristle like. Fine Scotch Bright pads will work in a pinch. If using the wheel, turn at very slow rpms so no heat develops and card the barrel (remove the loose rust) with the wheel. Then apply the next coat of dilute browning and repeat. However, just let the barrel rust for 2 hours or so and card again. You may have to repeat the cycles 20-30 times to create the color you desire but be patient. The goal is very fine grained rusting that leaves a smooth shiny translucent surface behind rather than a coarse, mat surface. After the final carding you can do several things. Wash the barrel in water and dry it and then simply heat the barrel a little and apply beeswax and buff it to a high polish. You can also wash the barrel with scalding (NOT BOILING) water, dry it and let it after rust a little, then a final carding. That will bring out deeper red colors and then heat and buff with beeswax. Finally, you can wash or sit the barrel in boiling water, remove, let dry and then gently rub it with fine Scotch Bright or 0000 steel wool, heat and buff it with beeswax. The boiling will turn the browning to a blue-black color.

Here is a barrel done by Pete Mazur, one of the best gun finishers around, that shows the fine, smooth, translucent finish found on high quality English guns.

dave

Dave's words of wisdom need to be heeded.

Similar threads

- Replies

- 3

- Views

- 353

- Replies

- 3

- Views

- 223

- Replies

- 29

- Views

- 2K