- Joined

- Apr 1, 2005

- Messages

- 1,143

- Reaction score

- 17

Yeha! :grin:

Well my birthday is coming up but unlike Mule Brain I aint rich like him. So I had to settle for something homemade instead.

I can tell you one thing, give me a little time and a welder and I can stick some stuff together. Actually Mud Dobbers could do a better job.

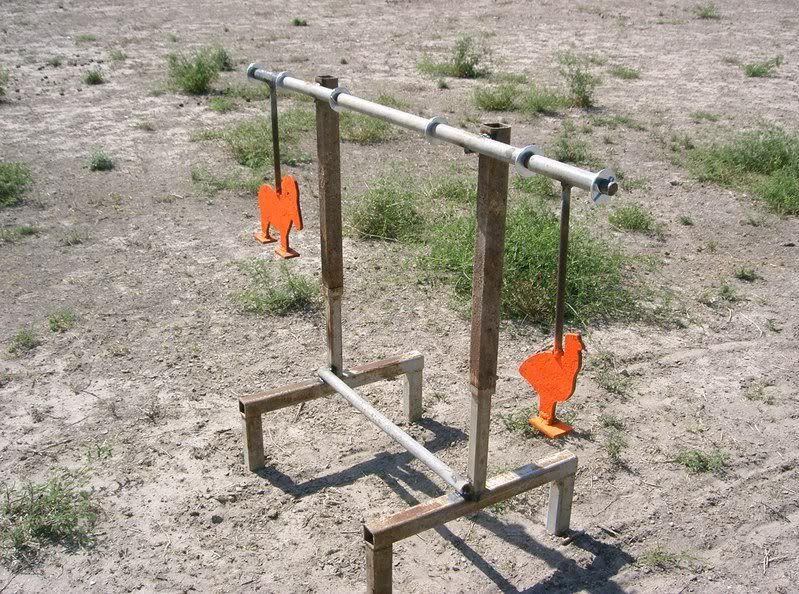

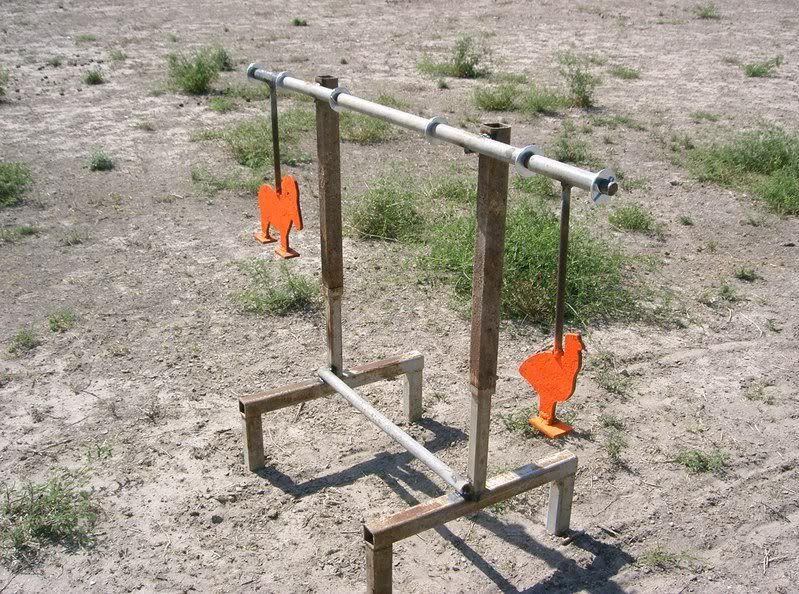

The Texas State Silhouette Shoot is coming up soon so I thought I would make a swinging silhouette target, one that I don't have to do down range and set up all the time. I think it came out pretty well considering the surplus material and a no-count welder immitator.

Enjoy the pics and make one for yourself, it's going to be a blast ringing the steel with Big 58! :thumbsup:

rabbit03

Well my birthday is coming up but unlike Mule Brain I aint rich like him. So I had to settle for something homemade instead.

I can tell you one thing, give me a little time and a welder and I can stick some stuff together. Actually Mud Dobbers could do a better job.

The Texas State Silhouette Shoot is coming up soon so I thought I would make a swinging silhouette target, one that I don't have to do down range and set up all the time. I think it came out pretty well considering the surplus material and a no-count welder immitator.

Enjoy the pics and make one for yourself, it's going to be a blast ringing the steel with Big 58! :thumbsup:

rabbit03