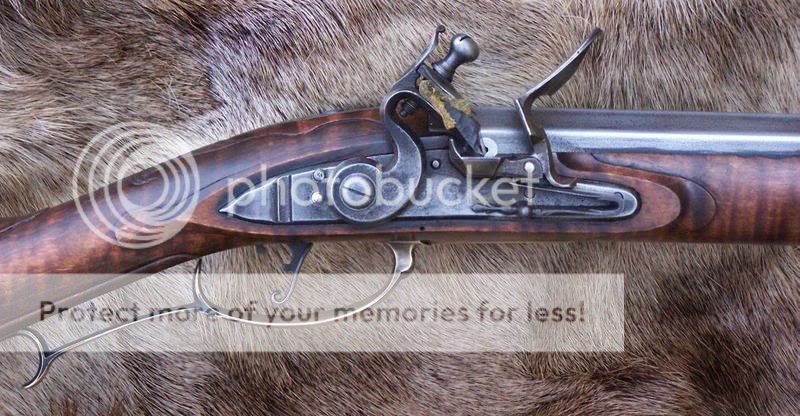

Okay thought the last thread was getting pretty lengthy so here's the part 2. Thanks for everyone's input on the forearm profile. I'm pretty happy with it now. I've started to shape the lock panel now and here's what I've got so far:

Keep in mind I haven't started to blend the molding lines. I just have the outlines carved. So yes, I know the front point is pretty drastic, it will be more suttle soon.

Keep in mind I haven't started to blend the molding lines. I just have the outlines carved. So yes, I know the front point is pretty drastic, it will be more suttle soon.