Nock's Patent breech was made long before the Percussion ignition system was in use.

Nock, an English gunsmith who made very high class shotguns wanted to come up with something that would be better than the traditional, vent thru the barrel wall design.

He reasoned, if a small anti-chamber was added below the powder, it would fill with powder when the gun was loaded.

The vent was located so the flash from the pan would pass directly into this anti-chamber.

The powder in the chamber, once ignited would create a jet of flame into the main powder charge which would cause it to burn faster and more cleanly.

It worked, and Nock Patented the idea.

His Patent breech caused a better ignition of the main powder charge and that not only increased the velocity of the shot but it created less fouling.

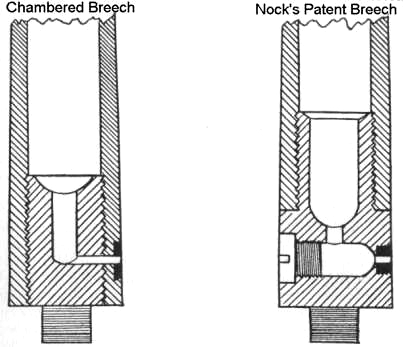

Below is a drawing of Nock's Patent breech.

Notice the large hole that connects the anti-chamber with the powder chamber. This is important because it does allow the anti-chamber to fill easily with powder so the powder is resting right next to the vent hole.

NocksPatent

NocksPatent by

James King, on Flickr

Manton, one of Nock's chief competitors wanted to do something that would give similar results but he did not want to pay royalties so he came up with the chambered breech.

His chambered breech uses a smaller chamber in the breech plug, directly in line with the bore of the gun.

Its location created a need to connect this chamber with the vent so it uses a flame channel between the vent hole and the chamber.

This flame channels extra length can cause problems. If it becomes fouled with oil or fouling, it can prevent the loose powder from the main powder charge to get completely to the vent hole.

This Manton design is what many of the modern reproduction guns use and although many of us modern people (incorrectly) call it a Patent breech, Manton never patented it.